2D/3D Laser Cutting Machine: Revolutionizing Manufacturing and Fabrication

Introduction

In the realm of modern manufacturing and fabrication, laser cutting machines have emerged as indispensable tools, offering unparalleled precision, speed, and versatility. Among these advanced machines, 2D/3D laser cutting machines stand out as the epitome of innovation, capable of cutting complex shapes and intricate designs with unmatched accuracy and efficiency.

Table of Content

- 1 2D/3D Laser Cutting Machine: Revolutionizing Manufacturing and Fabrication

- 1.1 Introduction

- 1.2 Understanding 2D/3D Laser Cutting

- 1.3 Advantages of 2D/3D Laser Cutting Machines

- 1.4 Understanding 2D/3D Laser Cutting

- 1.5 Applications of 2D/3D Laser Cutting Machines

- 1.6 Factors to Consider When Choosing a 2D/3D Laser Cutting Machine

- 1.7 Conclusion

- 1.8 FAQs

Understanding 2D/3D Laser Cutting

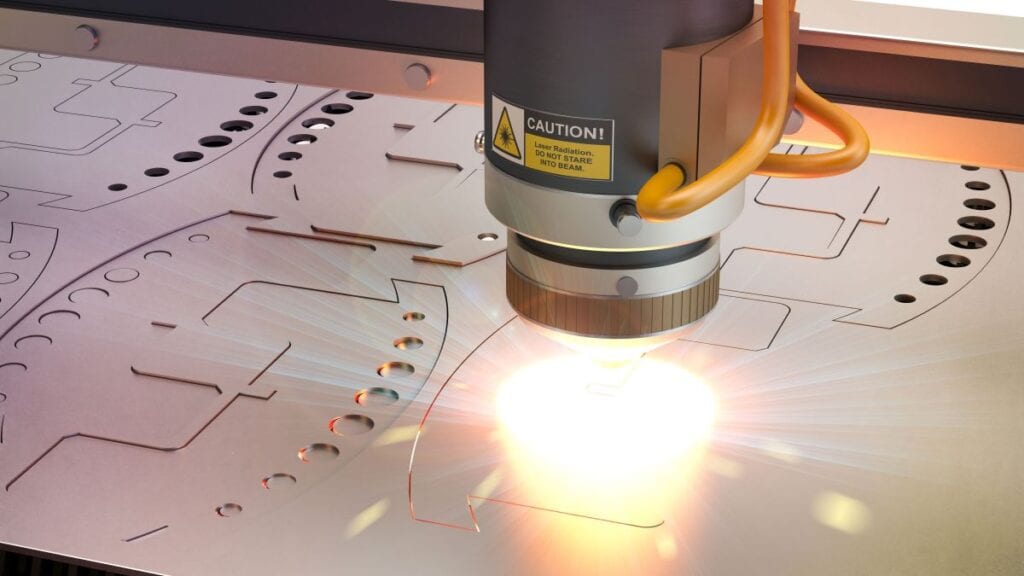

2D laser cutting machines utilize a focused laser beam to cut flat materials, such as sheet metal, acrylic, wood, and fabric. The laser beam is directed along a 2D plane, enabling precise cutting of shapes and patterns.

3D Laser Cutting:

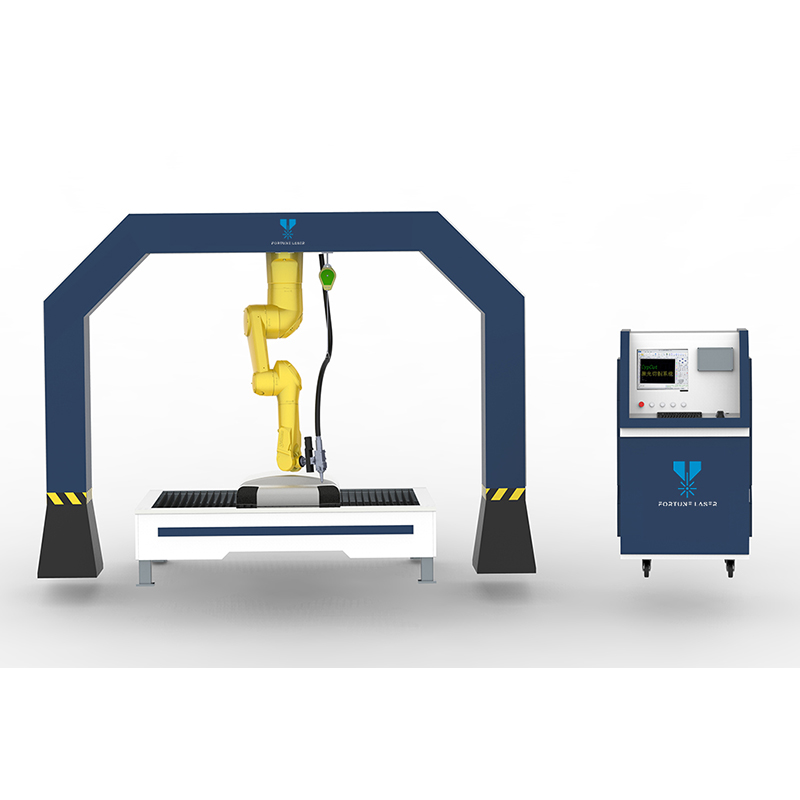

3D laser cutting machines extend the capabilities of 2D machines by incorporating a 5-axis or 6-axis motion system. This advanced system allows the laser beam to move in multiple directions, enabling the cutting of complex 3D shapes and geometries.

Advantages of 2D/3D Laser Cutting Machines

Precision and Accuracy:

Laser cutting machines offer unparalleled precision and accuracy, resulting in sharp, clean cuts with minimal distortion. This precision is crucial for intricate designs and applications requiring tight tolerances.

Speed and Efficiency:

Laser cutting is a highly efficient process, capable of cutting materials at rapid speeds. This increased productivity translates into faster turnaround times and reduced production costs.

Versatility:

2D/3D laser cutting machines can cut a wide range of materials, including metals, plastics, composites, and wood. This versatility makes them suitable for diverse applications across various industries.

In the realm of modern manufacturing and fabrication, laser cutting machines have emerged as indispensable tools, offering unparalleled precision, speed, and versatility. Among these advanced machines, 2D/3D laser cutting machines stand out as the epitome of innovation, capable of cutting complex shapes and intricate designs with unmatched accuracy and efficiency.

- 3d Layered Laser Cut 3D Layered Laser Cut: Revolutionizing Manufacturing And Design

- 3d Laser Cut Models Download 3D Laser Cut Models Download: A Comprehensive Guide

- 3d Laser Cutting Metal 3D Laser Cutting Metal: A Comprehensive Guide

- 3d Laser Cut Wooden Models For Sale 3D Laser Cut Wooden Models For Sale: A Comprehensive Guide

- What Is 3d Laser Cutting What Is 3D Laser Cutting?

Understanding 2D/3D Laser Cutting

2D Laser Cutting:

2D laser cutting machines utilize a focused laser beam to cut flat materials, such as sheet metal, acrylic, wood, and fabric. The laser beam is directed along a 2D plane, enabling precise cutting of shapes and patterns.

3D Laser Cutting:

3D laser cutting machines extend the capabilities of 2D machines by incorporating a 5-axis or 6-axis motion system. This advanced system allows the laser beam to move in multiple directions, enabling the cutting of complex 3D shapes and geometries.

Automation and Flexibility:

Many laser cutting machines feature automated systems, enabling unattended operation and seamless integration with automated production lines. This automation enhances productivity and reduces labor costs.

Applications of 2D/3D Laser Cutting Machines

Industrial Manufacturing:

2D/3D laser cutting machines are widely used in industrial manufacturing, including automotive, aerospace, electronics, and medical device production. They are employed for cutting sheet metal parts, chassis, and intricate components.

Prototyping and Model Making:

Laser cutting is ideal for prototyping and model making, allowing designers and engineers to quickly and accurately create physical models for testing and validation.

Signage and Graphics:

Laser cutting machines are used to produce high-quality signage, displays, and graphics for commercial and industrial applications. They can cut complex shapes and designs in a variety of materials, such as acrylic, metal, and wood.

Jewelry and Fashion:

Laser cutting is employed in the jewelry and fashion industries to create intricate designs and patterns in precious metals, fabrics, and leather. The precision and detail achievable with laser cutting enhances the aesthetics and value of these products.

Factors to Consider When Choosing a 2D/3D Laser Cutting Machine

Material Type and Thickness:

The type and thickness of the material to be cut should be considered when selecting a laser cutting machine. Different machines are designed for specific material types and thicknesses.

Cutting Speed and Accuracy:

The cutting speed and accuracy requirements of the application should be taken into account. Higher cutting speeds may be desired for production environments, while higher accuracy may be necessary for precision applications.

Automation and Software:

The level of automation and software compatibility should be evaluated. Advanced machines offer automated features and compatibility with design and manufacturing software for efficient operation.

Conclusion

2D/3D laser cutting machines have revolutionized manufacturing and fabrication by providing unparalleled precision, speed, and versatility. Their ability to cut complex shapes and intricate designs in a wide range of materials has made them essential tools in various industries. By carefully considering the application requirements and factors discussed above, businesses can select the optimal 2D/3D laser cutting machine to meet their specific needs and drive innovation and efficiency.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting cuts flat materials along a 2D plane, while 3D laser cutting utilizes a 5-axis or 6-axis motion system to cut complex 3D shapes and geometries.

Q: What materials can be cut with a 2D/3D laser cutting machine?

A: 2D/3D laser cutting machines can cut a wide range of materials, including metals, plastics, composites, wood, fabric, and leather.

Q: What are the advantages of laser cutting over traditional cutting methods?

A: Laser cutting offers higher precision, faster cutting speeds, reduced distortion, and greater versatility compared to traditional cutting methods like stamping or punching.