3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

Introduction

3D 6-axis laser cutting is an advanced manufacturing technique that has revolutionized the fabrication of complex and intricate parts. By combining the precision of laser cutting with the flexibility of 6-axis robotic movement, this technology enables manufacturers to achieve unparalleled levels of accuracy, speed, and efficiency.

Table of Content

- 1 3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

- 1.1 Introduction

- 1.2 What is 3D 6-Axis Laser Cutting?

- 1.3 Benefits of 3D 6-Axis Laser Cutting

- 1.4 Applications of 3D 6-Axis Laser Cutting

- 1.5 What is 3D 6-Axis Laser Cutting?

- 1.6 Benefits of 3D 6-Axis Laser Cutting

- 1.7 How 3D 6-Axis Laser Cutting Works

- 1.8 Considerations for 3D 6-Axis Laser Cutting

- 1.9 Conclusion

- 1.10 FAQs

What is 3D 6-Axis Laser Cutting?

Benefits of 3D 6-Axis Laser Cutting

3D 6-axis laser cutting offers numerous benefits over traditional manufacturing methods, including:

1. Precision and Accuracy: The combination of laser precision and robotic control ensures exceptional precision and accuracy in cutting complex shapes and intricate details.

2. Speed and Efficiency: The high-power laser beam and rapid robotic movement enable fast and efficient cutting, significantly reducing production time.

3. Flexibility and Versatility: The 6-axis robotic arm allows for cutting in various orientations and complex angles, providing maximum flexibility and versatility in fabrication.

4. Reduced Material Waste: The precise cutting process minimizes material waste, resulting in cost savings and reduced environmental impact.

5. Automation and Repeatability: 3D 6-axis laser cutting can be automated, ensuring consistent quality and repeatability in high-volume production.

Applications of 3D 6-Axis Laser Cutting

3D 6-axis laser cutting finds application in a wide range of industries, including:

1. Automotive: Fabrication of complex parts, such as body panels, exhaust systems, and interior components.

3D 6-axis laser cutting is an advanced manufacturing technique that has revolutionized the fabrication of complex and intricate parts. By combining the precision of laser cutting with the flexibility of 6-axis robotic movement, this technology enables manufacturers to achieve unparalleled levels of accuracy, speed, and efficiency.

- Shapeways Laser Cutting Shapeways Laser Cutting: A Comprehensive Guide To Advanced Manufacturing

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- Thingiverse Laser Cut Thingiverse Laser Cut: Unleashing The Power Of Digital Fabrication

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide To Precision Fabrication

- 3 D Laser Cutting 3D Laser Cutting: A Revolutionary Technology For Precision Manufacturing

What is 3D 6-Axis Laser Cutting?

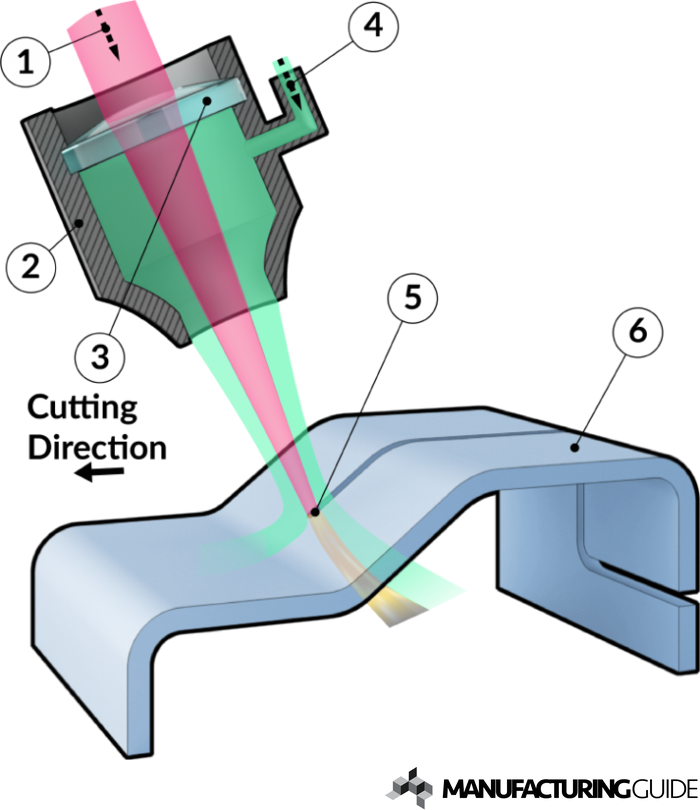

3D 6-axis laser cutting involves using a laser beam to cut and shape materials in three dimensions. The laser beam is guided by a robotic arm with six axes of movement, allowing it to reach and cut complex geometries with ease. This technology is particularly well-suited for cutting intricate shapes, curves, and angles, as well as for cutting materials that are difficult to process with traditional methods.

Benefits of 3D 6-Axis Laser Cutting

3D 6-axis laser cutting offers numerous benefits over traditional manufacturing methods, including:

1. Precision and Accuracy: The combination of laser precision and robotic control ensures exceptional precision and accuracy in cutting complex shapes and intricate details.

2. Aerospace: Cutting of lightweight and high-strength materials for aircraft and spacecraft components.

3. Medical: Production of medical devices, surgical instruments, and orthopedic implants.

4. Electronics: Fabrication of intricate electronic components, such as circuit boards and connectors.

5. Construction: Cutting of architectural panels, cladding, and other building components.

How 3D 6-Axis Laser Cutting Works

The process of 3D 6-axis laser cutting involves several key steps:

1. CAD/CAM Modeling: A computer-aided design (CAD) model of the desired part is created. This model is then converted into a computer-aided manufacturing (CAM) program that generates the cutting path for the robot.

2. Material Setup: The material to be cut is placed in the cutting area of the machine. The laser head is positioned above the material, and the robotic arm moves it along the cutting path.

3. Laser Cutting: The laser beam is activated, and it cuts through the material according to the CAM program. The robotic arm moves the laser head in three dimensions, ensuring precise cutting of complex geometries.

Considerations for 3D 6-Axis Laser Cutting

When considering 3D 6-axis laser cutting, several factors should be taken into account:

1. Material Properties: The type of material being cut will influence the laser cutting parameters, such as power, speed, and focus.

2. Laser Power: The laser power determines the thickness and types of materials that can be cut.

3. Cutting Speed: The cutting speed affects the quality and accuracy of the cut.

4. Robotic Accuracy: The precision of the robotic arm is crucial for achieving high-quality cuts.

Conclusion

3D 6-axis laser cutting is a transformative technology that has revolutionized the fabrication of complex and intricate parts. By combining the precision of laser cutting with the flexibility of 6-axis robotic movement, this technology enables manufacturers to achieve unparalleled levels of accuracy, speed, and efficiency. With its wide range of applications and benefits, 3D 6-axis laser cutting is poised to continue driving innovation and growth in various industries.

FAQs

1. What is the difference between 3-axis and 6-axis laser cutting?

3-axis laser cutting allows movement in the X, Y, and Z directions, while 6-axis laser cutting adds the ability to rotate around the X, Y, and Z axes. This additional flexibility enables cutting in complex angles and orientations.

2. Can 3D 6-axis laser cutting be used for all types of materials?

While 3D 6-axis laser cutting is versatile, it is most suitable for cutting metals, plastics, and composites. The specific materials that can be cut depend on the laser power and the material’s properties.

3. Is 3D 6-axis laser cutting automated?

Yes, 3D 6-axis laser cutting can be automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This automation ensures consistent quality and repeatability in high-volume production.

4. What are the advantages of 3D 6-axis laser cutting over traditional cutting methods?

3D 6-axis laser cutting offers higher precision, faster cutting speeds, increased flexibility, reduced material waste, and the ability to automate production.

5. What industries benefit the most from 3D 6-axis laser cutting?

Industries such as automotive, aerospace, medical, electronics, and construction heavily utilize 3D 6-axis laser cutting for the fabrication of complex and intricate parts.