3D Laser Cutting: Revolutionizing Manufacturing and Design

Introduction

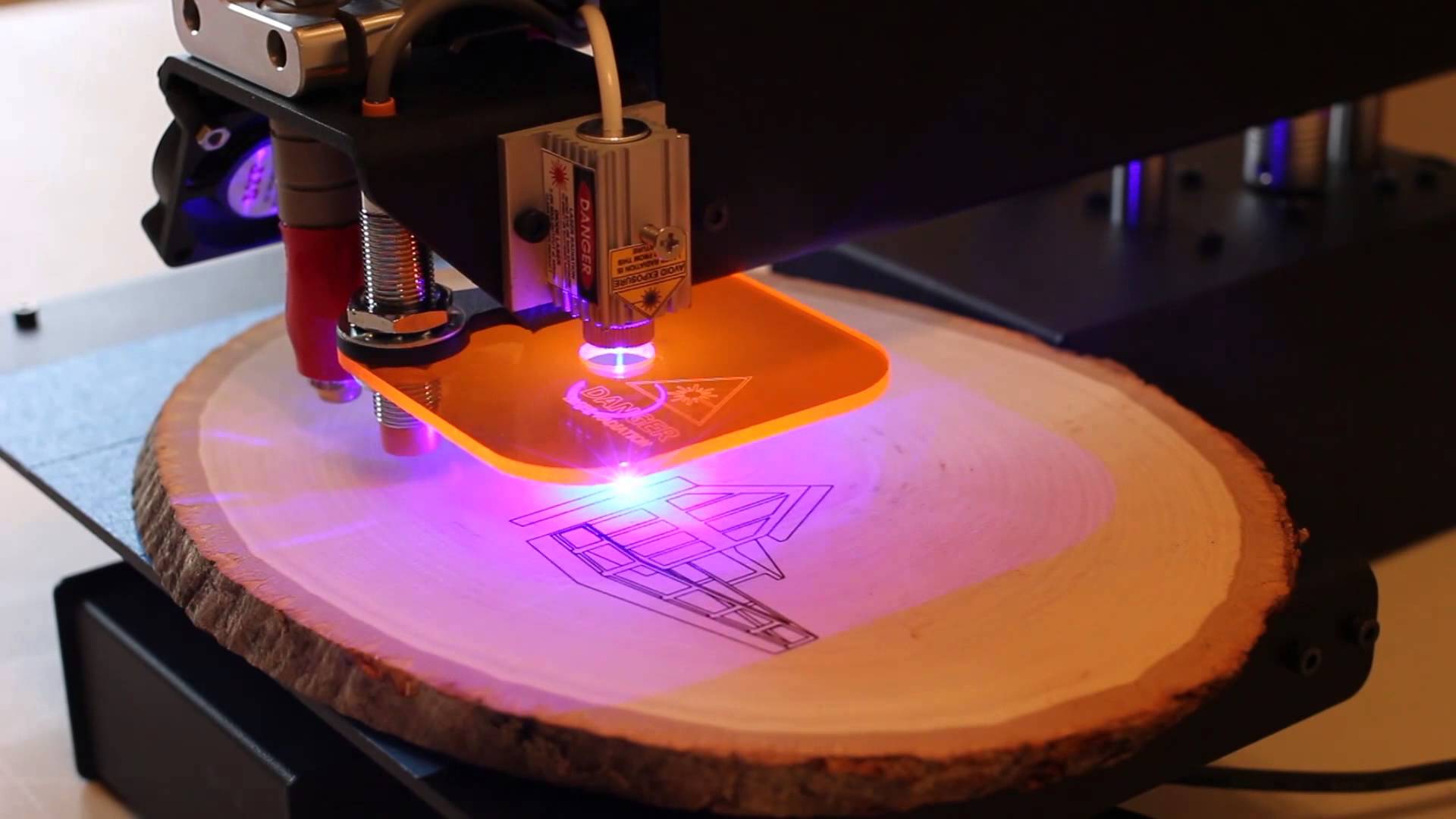

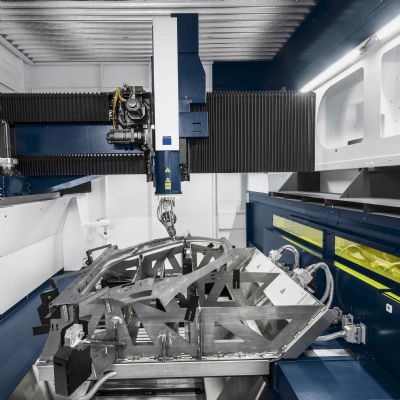

3D laser cutting has emerged as a transformative technology that has revolutionized the manufacturing and design industries. This advanced cutting process utilizes a high-powered laser to precisely cut and shape three-dimensional objects from various materials. With its unparalleled accuracy, versatility, and speed, 3D laser cutting has become an indispensable tool for a wide range of applications, from prototyping to mass production.

Table of Content

- 1 3D Laser Cutting: Revolutionizing Manufacturing and Design

- 1.1 Introduction

- 1.2 How Does 3D Laser Cutting Work?

- 1.3 Advantages of 3D Laser Cutting

- 1.4 Applications of 3D Laser Cutting

- 1.5 How Does 3D Laser Cutting Work?

- 1.6 Advantages of 3D Laser Cutting

- 1.7 Materials Suitable for 3D Laser Cutting

- 1.8 Factors Affecting 3D Laser Cutting Performance

- 1.9 Conclusion

- 1.10 Frequently Asked Questions (FAQs)

How Does 3D Laser Cutting Work?

Advantages of 3D Laser Cutting

3D laser cutting offers numerous advantages over traditional manufacturing methods:

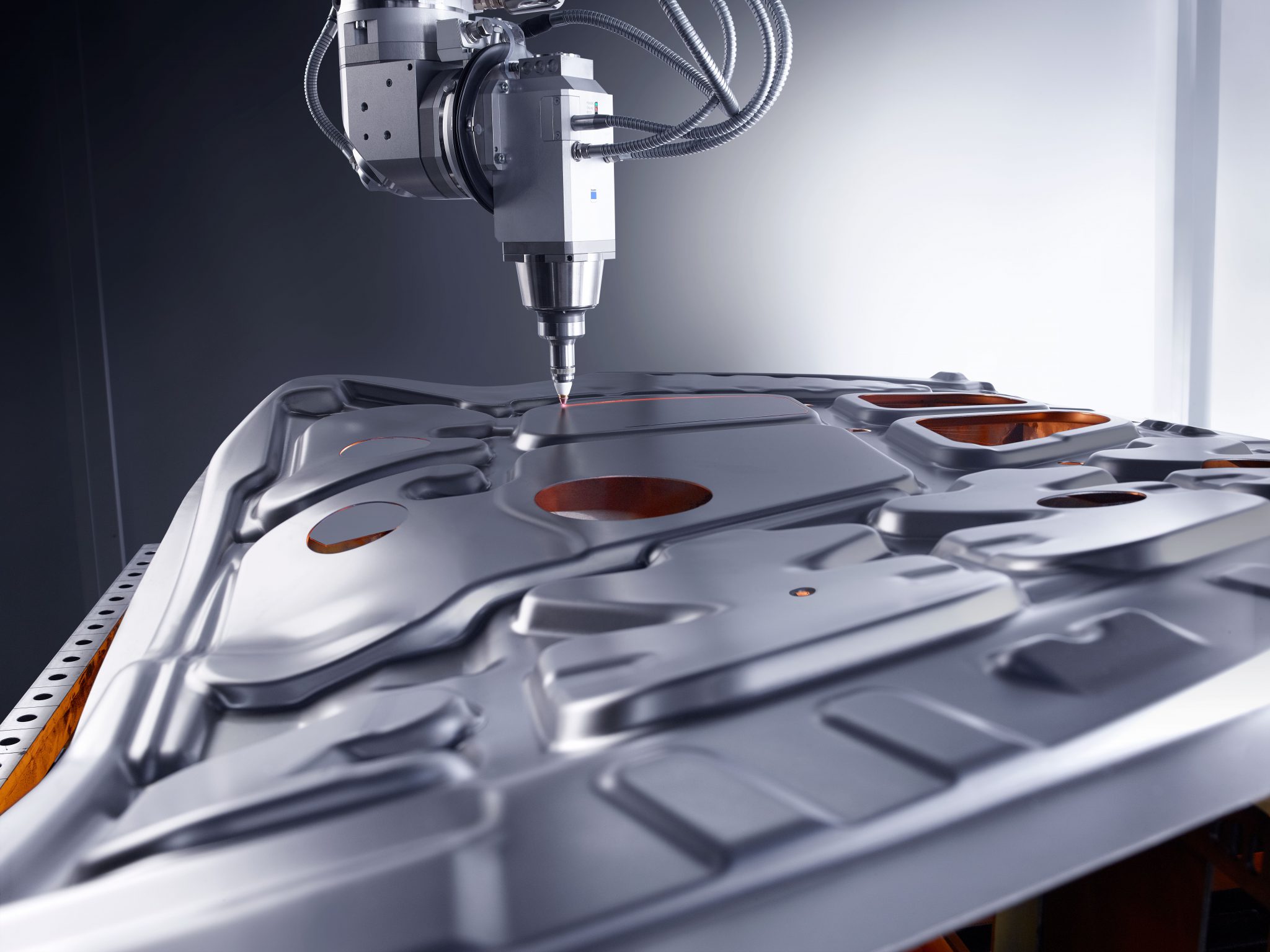

- High Precision: The laser beam’s focused nature allows for extremely precise cuts with minimal tolerances.

- Versatility: 3D laser cutting can cut a wide range of materials with varying thicknesses and shapes.

- Speed: The laser beam’s rapid cutting speed enables high-volume production.

- Complexity: 3D laser cutting can create intricate and complex geometries that are impossible to achieve with conventional cutting methods.

- Automation: The process is highly automated, reducing labor costs and improving efficiency.

Applications of 3D Laser Cutting

3D laser cutting has emerged as a transformative technology that has revolutionized the manufacturing and design industries. This advanced cutting process utilizes a high-powered laser to precisely cut and shape three-dimensional objects from various materials. With its unparalleled accuracy, versatility, and speed, 3D laser cutting has become an indispensable tool for a wide range of applications, from prototyping to mass production.

- 3d Laser Cut Butterfly 3D Laser Cut Butterfly: An Intricate And Delicate Work Of Art

- Sketchup For Laser Cutting SketchUp For Laser Cutting: A Comprehensive Guide

- 3d Laser Cutting Design 3D Laser Cutting Design: Revolutionizing Manufacturing And Creativity

- 3d Laser Cut Model 3D Laser Cut Models: A Comprehensive Guide

- Thingiverse Laser Cut Thingiverse Laser Cut: Unleashing The Power Of Digital Fabrication

How Does 3D Laser Cutting Work?

The principle behind 3D laser cutting is simple yet sophisticated. A high-power laser beam is focused through a lens and directed onto the workpiece. The laser beam interacts with the material, causing it to melt, vaporize, or ablate (remove material by vaporization). By precisely controlling the laser beam’s position and intensity, complex three-dimensional shapes can be cut from a variety of materials, including metals, plastics, wood, and even ceramics.

Advantages of 3D Laser Cutting

3D laser cutting offers numerous advantages over traditional manufacturing methods:

- Automotive: Prototyping, component manufacturing, and interior design

- Aerospace: Structural components, turbine blades, and lightweight parts

- Medical: Surgical tools, implants, and prosthetics

- Electronics: Circuit boards, connectors, and enclosures

- Jewelry: Intricate designs, custom pieces, and mass production

- Architecture: Model making, decorative elements, and signage

- Metals: Steel, stainless steel, aluminum, titanium, and copper

- Plastics: Acrylic, polycarbonate, ABS, and polyethylene

- Wood: Plywood, MDF, and hardwoods

- Ceramics: Porcelain, tiles, and glass

- Laser Power: Higher power lasers can cut thicker materials faster.

- Wavelength: Different wavelengths are suitable for different materials.

- Cutting Speed: Faster cutting speeds result in lower precision.

- Material Properties: The material’s composition, thickness, and reflectivity affect the cutting process.

The applications of 3D laser cutting span a wide range of industries, including:

Materials Suitable for 3D Laser Cutting

3D laser cutting is compatible with a wide range of materials, including:

Factors Affecting 3D Laser Cutting Performance

Several factors can influence the performance and quality of 3D laser cutting:

Conclusion

3D laser cutting has revolutionized manufacturing and design, offering unparalleled precision, versatility, and speed. Its wide range of applications and compatibility with diverse materials make it an indispensable tool for industries seeking to create complex and innovative products. As technology continues to advance, 3D laser cutting is poised to play an even more pivotal role in shaping the future of manufacturing and design.

Frequently Asked Questions (FAQs)

Q: What is the difference between 3D laser cutting and traditional cutting methods?

A: 3D laser cutting uses a focused laser beam to precisely cut three-dimensional objects, while traditional cutting methods use mechanical tools such as saws or cutters to remove material.

Q: What are the benefits of using 3D laser cutting?

A: 3D laser cutting offers high precision, versatility, speed, and the ability to create complex geometries.

Q: What materials can be cut with 3D laser cutting?

A: 3D laser cutting can cut a wide range of materials, including metals, plastics, wood, and ceramics.

Q: What factors affect the performance of 3D laser cutting?

A: Factors such as laser power, wavelength, cutting speed, and material properties influence the performance and quality of 3D laser cutting.

Q: What industries use 3D laser cutting?

A: 3D laser cutting is used in various industries, including automotive, aerospace, medical, electronics, jewelry, and architecture.