3D Laser Cut Designs: Unleashing Creativity and Precision

Introduction

3D laser cutting technology has revolutionized the design and manufacturing industries, enabling the creation of intricate and highly detailed three-dimensional objects. This article explores the captivating world of 3D laser cut designs, showcasing their versatility, applications, and potential to transform various sectors.

Table of Content

- 1 3D Laser Cut Designs: Unleashing Creativity and Precision

- 1.1 Introduction

- 2 H1: The Art of 3D Laser Cutting

- 2.2 H2: Advantages of 3D Laser Cutting

- 3 H1: Applications of 3D Laser Cut Designs

- 3.3 H2: Architecture and Design

- 4 H1: The Art of 3D Laser Cutting

- 4.4 H2: How 3D Laser Cutting Works

- 4.5 H2: Advantages of 3D Laser Cutting

- 4.6 H2: Product Design and Manufacturing

- 4.7 H2: Art and Crafts

- 5 H1: The Future of 3D Laser Cut Designs

- 5.8 H2: Advancements in Technology

- 5.9 H2: Emerging Applications

- 6 Conclusion

- 7 FAQs

- 7.10 Q: What materials can be laser cut in 3D?

- 7.11 Q: What software is used for 3D laser cutting?

- 7.12 Q: How do I choose the right laser cutter for 3D projects?

H1: The Art of 3D Laser Cutting

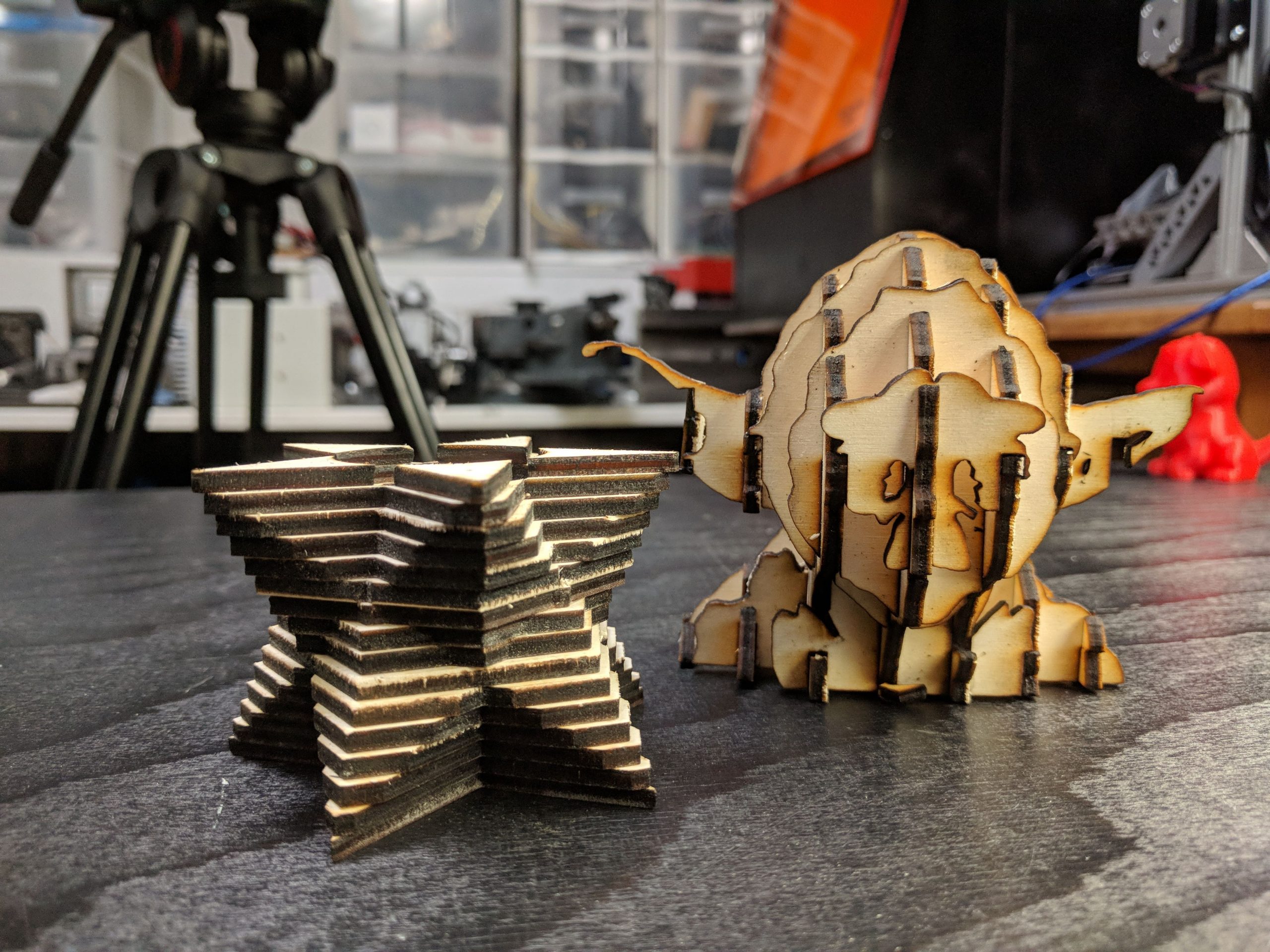

3D laser cutting involves a computer-controlled laser beam that precisely cuts and shapes materials such as wood, acrylic, metal, and fabric. The laser beam melts, vaporizes, or sublimates the material, creating a three-dimensional design. This process allows for complex and intricate cuts that would be challenging or impossible to achieve with traditional methods.

H2: Advantages of 3D Laser Cutting

- Precision and Detail: Lasers offer unparalleled precision and accuracy, enabling the creation of designs with sharp edges, smooth curves, and intricate details.

- Versatility: 3D laser cutting can work with a wide range of materials, opening up possibilities for diverse applications.

- Speed and Efficiency: Laser cutting is a fast and efficient process, reducing production time and increasing productivity.

- Design Flexibility: Computer-aided design (CAD) software allows for limitless design possibilities, enabling the creation of unique and personalized objects.

H1: Applications of 3D Laser Cut Designs

H2: Architecture and Design

3D laser cutting technology has revolutionized the design and manufacturing industries, enabling the creation of intricate and highly detailed three-dimensional objects. This article explores the captivating world of 3D laser cut designs, showcasing their versatility, applications, and potential to transform various sectors.

- 3d Cutting Design 3D Cutting Design: Unleashing Precision And Creativity In Manufacturing

- Anycubic Mega Pro Laser Cutting Anycubic Mega Pro: A Comprehensive Guide To Laser Cutting Precision

- 3d Laser Cutting Files 3D Laser Cutting Files: A Comprehensive Guide For Design And Fabrication

- 3d Laser Cutting Machine 3D Laser Cutting Machine: A Comprehensive Guide

- 3d Laser Cut Acrylic Letters 3D Laser Cut Acrylic Letters: A Comprehensive Guide

H1: The Art of 3D Laser Cutting

H2: How 3D Laser Cutting Works

3D laser cutting involves a computer-controlled laser beam that precisely cuts and shapes materials such as wood, acrylic, metal, and fabric. The laser beam melts, vaporizes, or sublimates the material, creating a three-dimensional design. This process allows for complex and intricate cuts that would be challenging or impossible to achieve with traditional methods.

H2: Advantages of 3D Laser Cutting

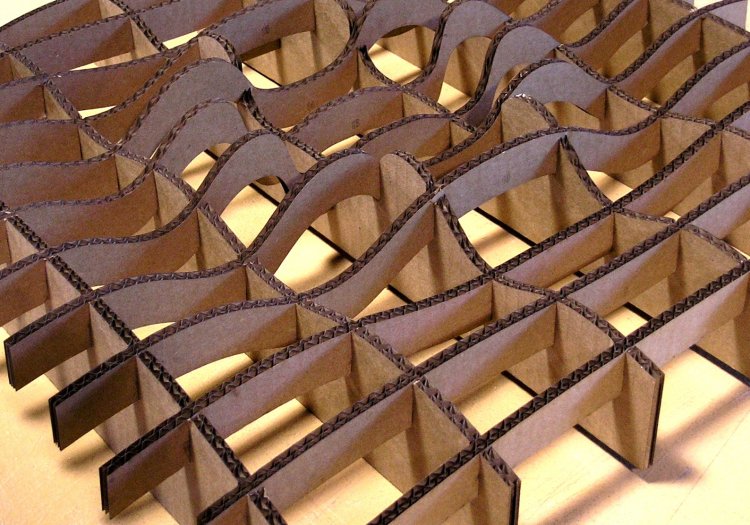

3D laser cut designs are transforming architecture and interior design, creating eye-catching structures, wall panels, and furniture. The ability to customize and create complex geometries has led to innovative and aesthetically pleasing spaces.

H2: Product Design and Manufacturing

3D laser cutting plays a vital role in product design and manufacturing, enabling the creation of prototypes, custom parts, and finished products. The precision and detail of laser cutting ensures high-quality and consistent results.

H2: Art and Crafts

3D laser cutting has opened new avenues for artists and crafters, enabling the creation of intricate sculptures, jewelry, and decorative pieces. The ability to cut and shape materials with precision allows for unique and expressive designs.

H1: The Future of 3D Laser Cut Designs

H2: Advancements in Technology

Continuous advancements in laser technology, such as ultra-short pulsed lasers, are expanding the capabilities of 3D laser cutting. These lasers offer even greater precision and detail, enabling the creation of even more intricate designs.

H2: Emerging Applications

3D laser cutting is finding new applications in industries such as aerospace, medical, and automotive. Its precision and versatility make it ideal for creating custom components, surgical instruments, and prototypes.

Conclusion

3D laser cut designs are revolutionizing various industries, enabling the creation of intricate and highly detailed three-dimensional objects. The precision, versatility, and design flexibility of laser cutting technology offer endless possibilities for innovation and creativity. As technology continues to advance, we can expect even more groundbreaking applications and stunning designs in the future.

FAQs

Q: What materials can be laser cut in 3D?

A: 3D laser cutting can work with a wide range of materials, including wood, acrylic, metal, fabric, and some plastics.

Q: What software is used for 3D laser cutting?

A: CAD software is typically used to create the 3D designs for laser cutting. Popular software options include AutoCAD, SolidWorks, and SketchUp.

Q: How do I choose the right laser cutter for 3D projects?

A: Consider factors such as the materials you need to cut, the desired precision, and the size of your projects. Consult with laser cutter manufacturers or experts for guidance.