3D Laser Cut Files: Unleashing Creativity and Innovation

Introduction

In the realm of digital fabrication, 3D laser cut files have emerged as a transformative tool, empowering makers, designers, and businesses alike to realize their creative visions with unparalleled precision and versatility. Laser cutting technology utilizes a focused laser beam to cut, engrave, and shape various materials, including wood, acrylic, metal, and fabric, opening up endless possibilities for creating intricate designs, prototypes, and finished products.

Table of Content

- 1 3D Laser Cut Files: Unleashing Creativity and Innovation

- 1.1 Introduction

- 1.2 Understanding 3D Laser Cut Files

- 1.3 File Formats and Compatibility

- 1.4 Designing for Laser Cutting

- 1.5 Understanding 3D Laser Cut Files

- 1.6 File Formats and Compatibility

- 1.7 Applications of 3D Laser Cut Files

- 1.8 Benefits of Using 3D Laser Cut Files

- 1.9 Conclusion

- 1.10 FAQs

Understanding 3D Laser Cut Files

File Formats and Compatibility

Various file formats are used for 3D laser cut files, each with its unique characteristics and compatibility with different laser cutting software. Common file formats include:

- DXF (Drawing Exchange Format): A widely used format for 2D and 3D drawings, compatible with most laser cutting software.

- DWG (AutoCAD Drawing Database): A proprietary format developed by Autodesk, used primarily for AutoCAD drawings.

- AI (Adobe Illustrator): A vector-based format commonly used for creating illustrations and graphics, compatible with some laser cutting software.

- SVG (Scalable Vector Graphics): An XML-based format for vector graphics, suitable for creating simple 2D designs for laser cutting.

Designing for Laser Cutting

To optimize the laser cutting process and achieve desired results, it is essential to consider several design principles:

In the realm of digital fabrication, 3D laser cut files have emerged as a transformative tool, empowering makers, designers, and businesses alike to realize their creative visions with unparalleled precision and versatility. Laser cutting technology utilizes a focused laser beam to cut, engrave, and shape various materials, including wood, acrylic, metal, and fabric, opening up endless possibilities for creating intricate designs, prototypes, and finished products.

- 3d 6 Axis Laser Cutting 3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- Snapmaker Cnc Cutting Wood Snapmaker CNC: Unleashing Precision And Versatility For Woodworking

- 3d Cnc Cutting Design 3D CNC Cutting Design: A Comprehensive Guide

- 3d Laser Wood Cutter 3D Laser Wood Cutter: A Comprehensive Guide

Understanding 3D Laser Cut Files

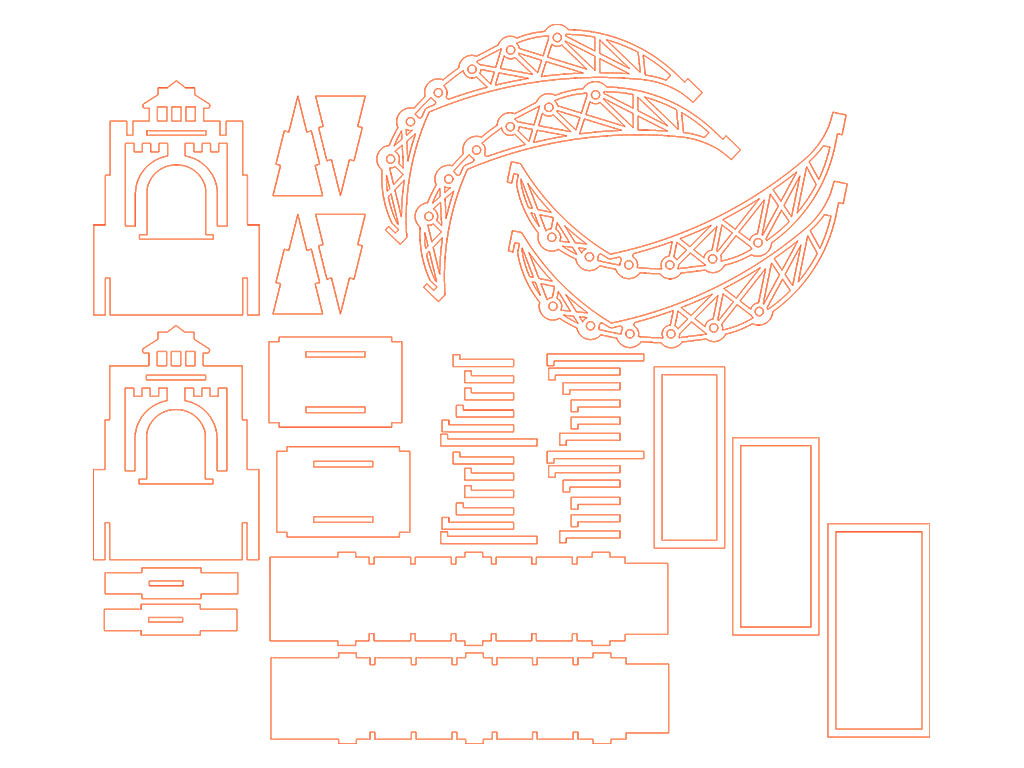

3D laser cut files are digital blueprints that define the three-dimensional shape and design of an object to be cut using a laser cutter. These files are typically created using computer-aided design (CAD) software, where the user designs the object in a virtual environment and generates the necessary cutting instructions.

File Formats and Compatibility

Various file formats are used for 3D laser cut files, each with its unique characteristics and compatibility with different laser cutting software. Common file formats include:

- Line Thickness: The thickness of the lines in the laser cut file determines the width of the cut. Laser cutters typically have a minimum line width that they can cut, which varies depending on the material and laser power.

- Kerf: Kerf refers to the width of the material removed by the laser beam during cutting. It is important to account for kerf when designing joints and fitting components together.

- Material Thickness: The thickness of the material being cut determines the laser power and cutting speed required. Different materials have varying laser absorption and cutting properties.

- Grain Direction (for Wood): For wood materials, it is crucial to consider the grain direction. Cutting against the grain can result in splintering or uneven cuts.

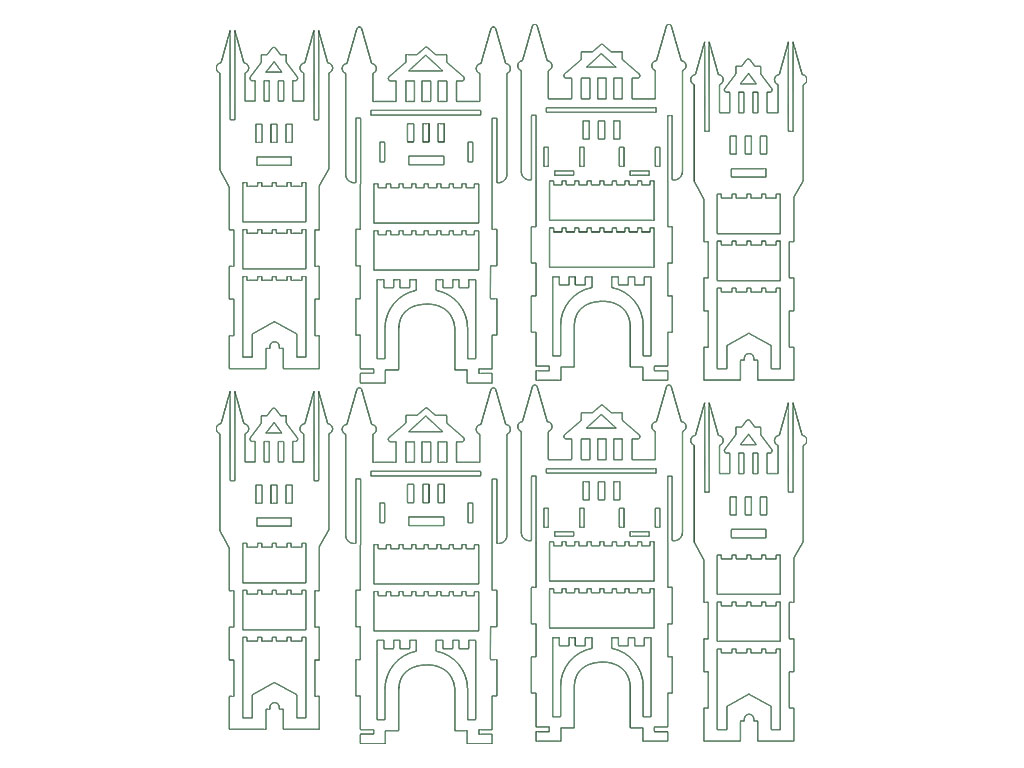

- Prototyping and Design: Laser cutting enables rapid prototyping of product concepts and design iterations, allowing designers to visualize and test their ideas quickly.

- Product Manufacturing: Laser cut files facilitate mass production of intricate parts, components, and finished products, ensuring consistent quality and precision.

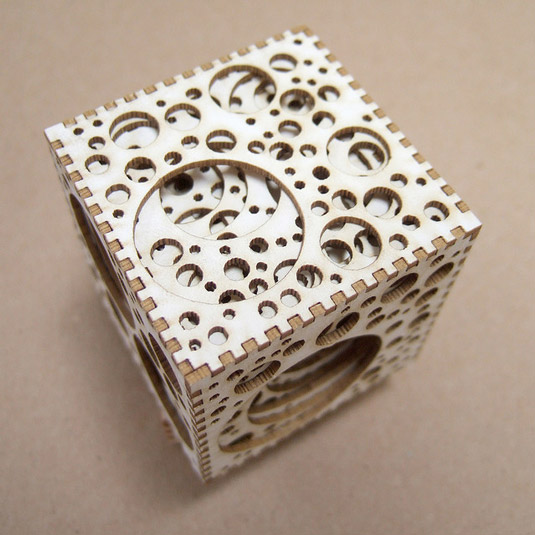

- Art and Crafts: Laser cutting empowers artists and crafters to create unique and personalized items, such as jewelry, home décor, and custom gifts.

- Architecture and Engineering: Laser cut files are used in architectural modeling, creating scale models and complex building components with high accuracy.

- Robotics and Automation: Laser cutting is employed in the fabrication of robotic parts, sensors, and other components for automated systems.

- Precision and Accuracy: Laser cutting provides unparalleled precision and accuracy, ensuring consistent and repeatable results.

- Versatility: Laser cutters can cut a wide range of materials, from thin paper to thick metals, expanding design possibilities.

- Speed and Efficiency: Laser cutting is a fast and efficient process, enabling rapid production of parts and products.

- Cost-Effectiveness: Laser cutting can be cost-effective, especially for small-batch production and customized items.

- Sustainability: Laser cutting minimizes material waste and reduces the need for manual labor, promoting sustainability.

Applications of 3D Laser Cut Files

The applications of 3D laser cut files are boundless, spanning various industries and creative pursuits:

Benefits of Using 3D Laser Cut Files

Leveraging 3D laser cut files offers numerous benefits:

Conclusion

3D laser cut files have revolutionized the way we design, prototype, and manufacture objects. With their exceptional precision, versatility, and cost-effectiveness, laser cut files empower makers, designers, and businesses to unleash their creativity and innovate like never before. As technology continues to advance, we can expect even more transformative applications of 3D laser cut files in the years to come.

FAQs

Q: What software is used to create 3D laser cut files?

A: Popular CAD software for creating 3D laser cut files include Autodesk Fusion 360, SolidWorks, and Rhino 3D.

Q: How do I optimize my laser cut files for best results?

A: Ensure proper line thickness, account for kerf, consider material thickness and grain direction (for wood), and test your designs before committing to large-scale production.

Q: What is the difference between 2D and 3D laser cut files?

A: 2D laser cut files define flat shapes, while 3D laser cut files define three-dimensional objects. 3D files provide additional depth and complexity to the designs.

Q: Can I cut any material with a laser cutter?

A: Laser cutters can cut a wide range of materials, including wood, acrylic, metal, fabric, and leather. However, the compatibility and optimal cutting parameters vary depending on the material.

Q: How do I find laser cutting services?

A: You can find laser cutting services through online marketplaces, local makerspaces, or by contacting professional laser cutting companies.