3D Laser Cut Models: Unleashing the Power of Precision and Creativity

Introduction

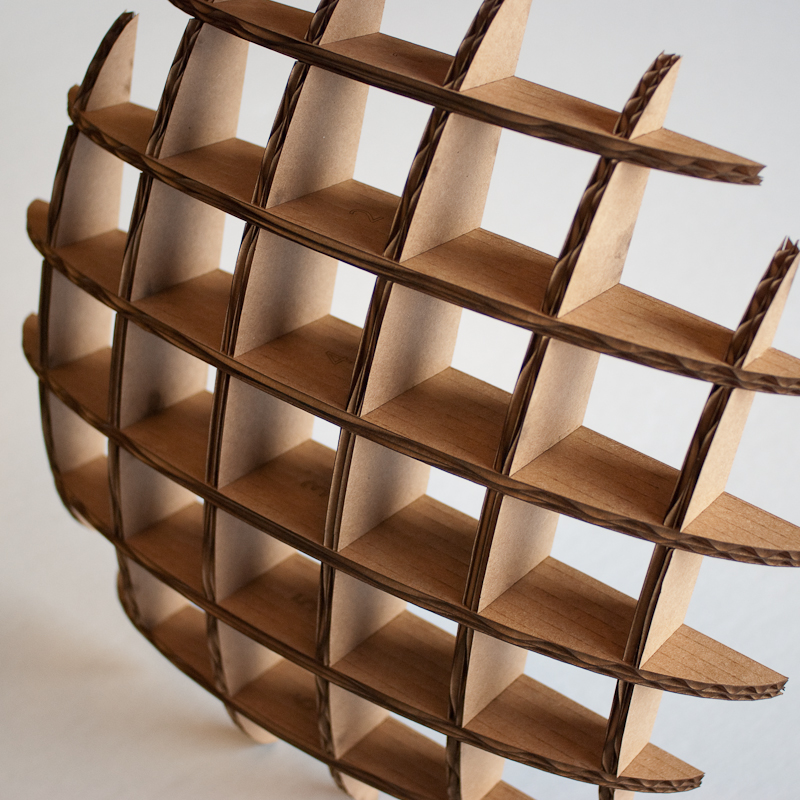

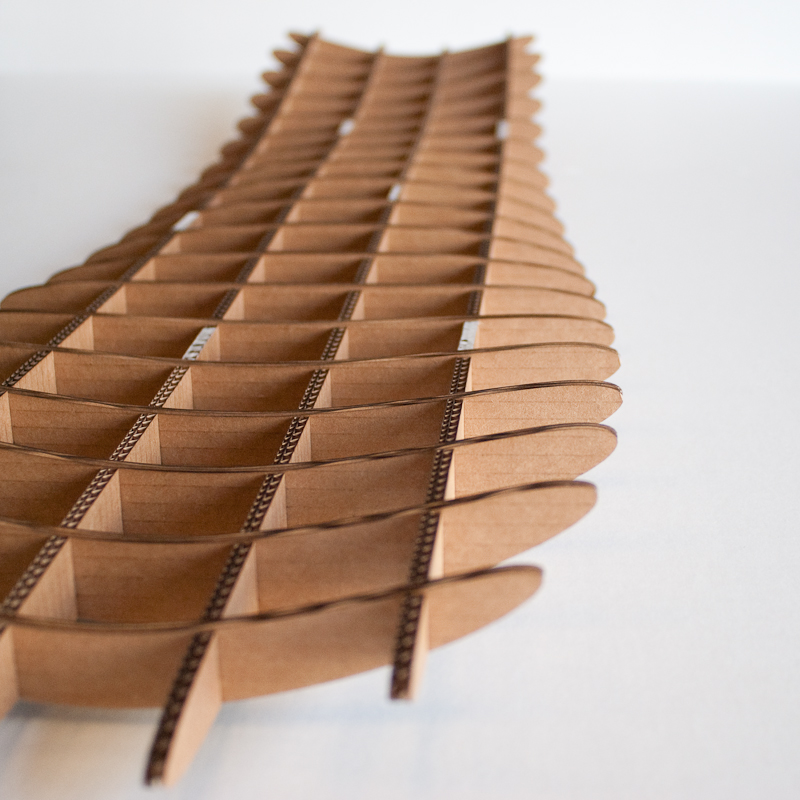

In the realm of fabrication and design, 3D laser cut models have emerged as a transformative force, unlocking unparalleled levels of precision and creativity. These models, meticulously crafted using advanced laser cutting technology, offer a wide range of applications, from architectural visualization to personalized décor. This comprehensive guide delves into the captivating world of 3D laser cut models, exploring their advantages, applications, and the intricate processes involved in their creation.

Table of Content

H2: Advantages of 3D Laser Cut Models

Precision and Accuracy: Laser cutting utilizes a highly focused laser beam, resulting in precise cuts with minimal deviation. This level of accuracy ensures the creation of intricate designs and complex shapes with exceptional detail.

Versatility: Laser cutters can work with a diverse range of materials, including wood, acrylic, metal, and paper. This versatility enables the production of models for a wide variety of applications and industries.

Customization: 3D laser cut models allow for unparalleled customization, enabling the creation of unique and personalized designs. From intricate architectural models to personalized nameplates, the possibilities are limitless.

Speed and Efficiency: Laser cutting is a rapid and efficient process, significantly reducing production time compared to manual fabrication methods. This efficiency translates into cost savings and faster turnaround times.

H2: Applications of 3D Laser Cut Models

The applications of 3D laser cut models extend across various industries and disciplines:

Architecture and Design: Laser cut models play a crucial role in architectural visualization, allowing architects to create precise scale models of buildings and structures. These models provide a tangible representation of design concepts, enabling better communication with clients and stakeholders.

Product Development: In product development, laser cut models serve as prototypes and mockups, helping designers refine designs and test functionality before mass production. This iterative process reduces development time and improves product quality.

Personalized Décor: Laser cut models offer unique opportunities for personalized décor. From intricate wall art to custom furniture, these models add a touch of individuality and creativity to any space.

Education and Research: Laser cut models have educational value in fields such as engineering, science, and art. They provide hands-on learning experiences and enable students to explore complex concepts in a tangible way.

In the realm of fabrication and design, 3D laser cut models have emerged as a transformative force, unlocking unparalleled levels of precision and creativity. These models, meticulously crafted using advanced laser cutting technology, offer a wide range of applications, from architectural visualization to personalized décor. This comprehensive guide delves into the captivating world of 3D laser cut models, exploring their advantages, applications, and the intricate processes involved in their creation.

- 3d Laser Cut Bee 3D Laser Cut Bee: A Buzzing Masterpiece Of Precision And Creativity

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

- Laser Cutting Ender 3 Laser Cutting Ender 3: A Comprehensive Guide To Enhancing Your 3D Printer’s Capabilities

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide

H2: Advantages of 3D Laser Cut Models

3D laser cut models boast a multitude of advantages that set them apart from traditional fabrication methods:

Precision and Accuracy: Laser cutting utilizes a highly focused laser beam, resulting in precise cuts with minimal deviation. This level of accuracy ensures the creation of intricate designs and complex shapes with exceptional detail.

Versatility: Laser cutters can work with a diverse range of materials, including wood, acrylic, metal, and paper. This versatility enables the production of models for a wide variety of applications and industries.

Customization: 3D laser cut models allow for unparalleled customization, enabling the creation of unique and personalized designs. From intricate architectural models to personalized nameplates, the possibilities are limitless.

H2: Process of Creating 3D Laser Cut Models

The creation of 3D laser cut models involves a meticulous process:

Design: The first step involves designing the model using computer-aided design (CAD) software. This design determines the shape, size, and intricate details of the model.

Material Selection: The choice of material depends on the desired properties and application of the model. Factors to consider include durability, flexibility, and aesthetics.

Laser Cutting: The designed model is then transferred to a laser cutter, which uses a focused laser beam to cut the material with precision. The laser’s power, speed, and focus are carefully calibrated to achieve the desired results.

Assembly: For complex models, multiple laser-cut components are assembled together using adhesives, fasteners, or interlocking joints. This process requires careful alignment and precision to ensure the model’s stability and accuracy.

H2: Conclusion

3D laser cut models have revolutionized the field of fabrication and design, offering unparalleled precision, versatility, and customization. Their applications span a wide range of industries, from architecture and product development to personalized décor and education. The intricate process involved in their creation requires expertise in design, material selection, and laser cutting techniques. As technology continues to advance, the possibilities for 3D laser cut models will continue to expand, unlocking new frontiers of creativity and innovation.

FAQs

Q: What materials can be used for 3D laser cut models?

A: A wide range of materials can be used, including wood, acrylic, metal, paper, and cardboard.

Q: How accurate are 3D laser cut models?

A: Laser cutting offers exceptional accuracy, with deviations typically measured in thousandths of an inch.

Q: Can 3D laser cut models be customized?

A: Yes, laser cutting enables the creation of highly customized models based on specific designs and requirements.

Q: What is the typical production time for 3D laser cut models?

A: Production time varies depending on the complexity of the model and the number of units required. However, laser cutting offers significant speed and efficiency compared to manual fabrication methods.

Q: What industries benefit from 3D laser cut models?

A: 3D laser cut models find applications in architecture, product development, personalized décor, education, research, and various other industries.