3D Laser Cut Patterns: Unleashing Design Possibilities in the Third Dimension

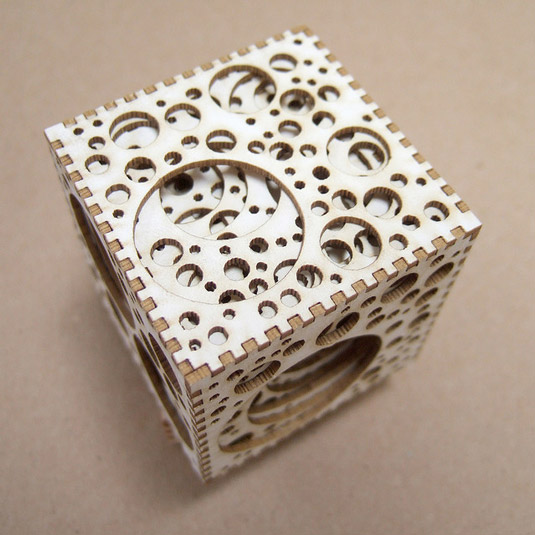

Laser cutting technology has revolutionized the world of design, enabling the creation of intricate and precise patterns in a wide range of materials. 3D laser cutting takes this technology a step further, allowing designers and manufacturers to create three-dimensional objects and patterns with unparalleled precision and detail.

H2: Understanding 3D Laser Cutting Technology

Table of Content

- 1 3D Laser Cut Patterns: Unleashing Design Possibilities in the Third Dimension

- 1.1 H2: Understanding 3D Laser Cutting Technology

- 1.2 H3: Applications of 3D Laser Cut Patterns

- 1.3 H2: Understanding 3D Laser Cutting Technology

- 1.4 H2: Materials Suitable for 3D Laser Cutting

- 1.5 H2: Benefits of 3D Laser Cutting

- 1.6 H2: Design Considerations for 3D Laser Cut Patterns

- 1.7 H2: Conclusion

- 1.8 FAQs

3D laser cutting involves using a computer-controlled laser to cut or engrave patterns into a three-dimensional object. The laser beam is directed onto the material, vaporizing or melting it to create the desired shape. Unlike traditional 2D laser cutting, 3D laser cutting allows for the creation of complex geometries and intricate details on all sides of the object.

A wide variety of materials can be used for 3D laser cutting, including:

- Wood: Ideal for creating decorative items, furniture, and architectural elements.

- Acrylic: A lightweight and versatile material suitable for signage, display stands, and jewelry.

- Metal: Can be cut precisely to create durable and functional components.

- Glass: Used for intricate engraving and cutting of delicate designs.

- Leather: Creates unique and personalized accessories, apparel, and home décor.

H3: Applications of 3D Laser Cut Patterns

The applications of 3D laser cut patterns are vast and diverse, spanning various industries:

H2: Understanding 3D Laser Cutting Technology

- 3d Laser Cut Models Download 3D Laser Cut Models Download: A Comprehensive Guide

- 3d Laser Crystal Engraving Machine 3D Laser Crystal Engraving Machine: Unlocking Limitless Creative Possibilities

- 3d Laser Cut Template 3D Laser Cut Template: A Comprehensive Guide

- Sketchup Laser Cutting H1: Unleashing The Power Of SketchUp Laser Cutting: A Comprehensive Guide

- Wedding Invitations 3d Laser Cut Wedding Invitations 3D Laser Cut: A Guide To The Ultimate First Impression

3D laser cutting involves using a computer-controlled laser to cut or engrave patterns into a three-dimensional object. The laser beam is directed onto the material, vaporizing or melting it to create the desired shape. Unlike traditional 2D laser cutting, 3D laser cutting allows for the creation of complex geometries and intricate details on all sides of the object.

H2: Materials Suitable for 3D Laser Cutting

A wide variety of materials can be used for 3D laser cutting, including:

- Wood: Ideal for creating decorative items, furniture, and architectural elements.

- Architecture: Custom panels, decorative elements, and architectural models.

- Interior Design: Unique lighting fixtures, furniture, and wall art.

- Product Design: Prototyping, functional components, and personalized products.

- Fashion: Custom jewelry, accessories, and clothing embellishments.

- Art and Sculpture: Intricate sculptures, wall hangings, and installations.

- Precision: Laser beams provide highly accurate and repeatable cuts, ensuring precise dimensions and intricate details.

- Speed: Laser cutting is a fast process, allowing for rapid production of large quantities of parts.

- Versatility: Can cut a wide range of materials, enabling designers to explore different aesthetic and functional possibilities.

- Customization: Allows for the creation of unique and personalized objects tailored to specific needs.

- Sustainability: Minimal waste production and reduced energy consumption compared to traditional manufacturing methods.

- Material Thickness: The thickness of the material will determine the depth and precision of the cuts.

- Cut Path: The laser beam’s path through the material must be carefully planned to avoid overlaps or inconsistencies.

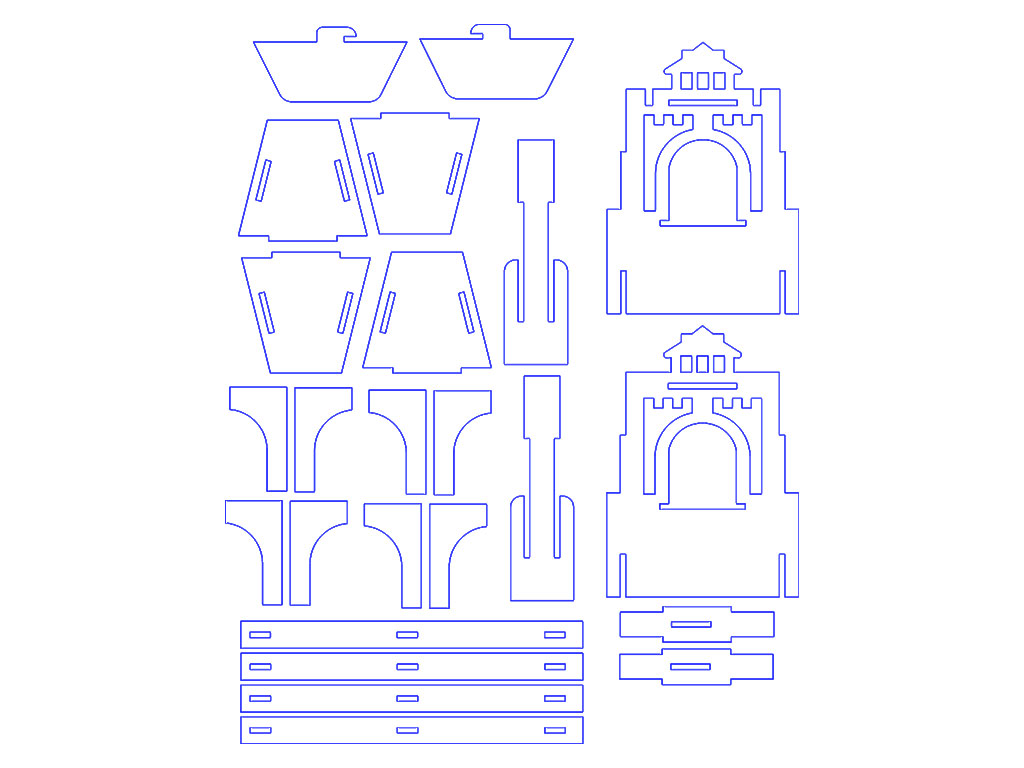

- Joinery: Consider how different parts will be joined together to ensure structural integrity and aesthetic appeal.

- Detailing: Intricate details can be achieved with precision, but it may require multiple passes or specialized techniques.

- File Format: Ensure the design file is in a compatible format for the laser cutting machine.

H2: Benefits of 3D Laser Cutting

3D laser cutting offers numerous advantages over traditional manufacturing methods:

H2: Design Considerations for 3D Laser Cut Patterns

When designing for 3D laser cutting, several factors should be considered:

H2: Conclusion

3D laser cut patterns have revolutionized the design process, enabling the creation of complex and intricate objects with unparalleled precision and detail. The versatility, speed, and sustainability of this technology make it an invaluable tool for designers and manufacturers across various industries. As technology continues to advance, the possibilities for 3D laser cut patterns are endless, pushing the boundaries of design and innovation.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting creates flat patterns on a two-dimensional surface, while 3D laser cutting creates three-dimensional objects and patterns.

Q: Can 3D laser cutting be used on any material?

A: While a wide range of materials can be laser cut, the suitability depends on factors such as thickness, density, and heat tolerance.

Q: How accurate is 3D laser cutting?

A: Laser cutting provides highly accurate cuts, with tolerances typically within a few thousandths of an inch.

Q: Is 3D laser cutting expensive?

A: The cost of 3D laser cutting varies depending on the material, complexity of the design, and quantity produced. However, it can be a cost-effective solution for small-batch production and prototyping.

Q: What industries use 3D laser cut patterns?

A: 3D laser cut patterns are used in various industries, including architecture, interior design, product design, fashion, and art.