3D Laser Cut Template: A Comprehensive Guide

Introduction

3D laser cut templates have revolutionized the fabrication industry, enabling the creation of intricate and precise three-dimensional objects from various materials. These templates guide laser cutting machines to cut and shape materials with unparalleled accuracy and efficiency, opening up a world of possibilities for designers, engineers, and manufacturers.

Table of Content

- 1 3D Laser Cut Template: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Advantages of 3D Laser Cut Templates

- 1.3 H2: Types of 3D Laser Cut Templates

- 1.4 H3: Material Considerations for 3D Laser Cutting

- 1.5 H1: Advantages of 3D Laser Cut Templates

- 1.6 H4: Applications of 3D Laser Cut Templates

- 1.7 H5: Design Considerations for 3D Laser Cut Templates

- 1.8 H6: Conclusion

- 1.9 FAQs

H1: Advantages of 3D Laser Cut Templates

2. Design Flexibility: Templates allow for the creation of complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

3. Material Versatility: 3D laser cut templates can be used with a wide range of materials, including metals, plastics, wood, and composites.

4. Cost-Effectiveness: Laser cutting templates reduce waste and streamline production processes, leading to significant cost savings.

5. Time-Saving: Laser cutting with templates is a highly efficient process, significantly reducing lead times and speeding up production.

H2: Types of 3D Laser Cut Templates

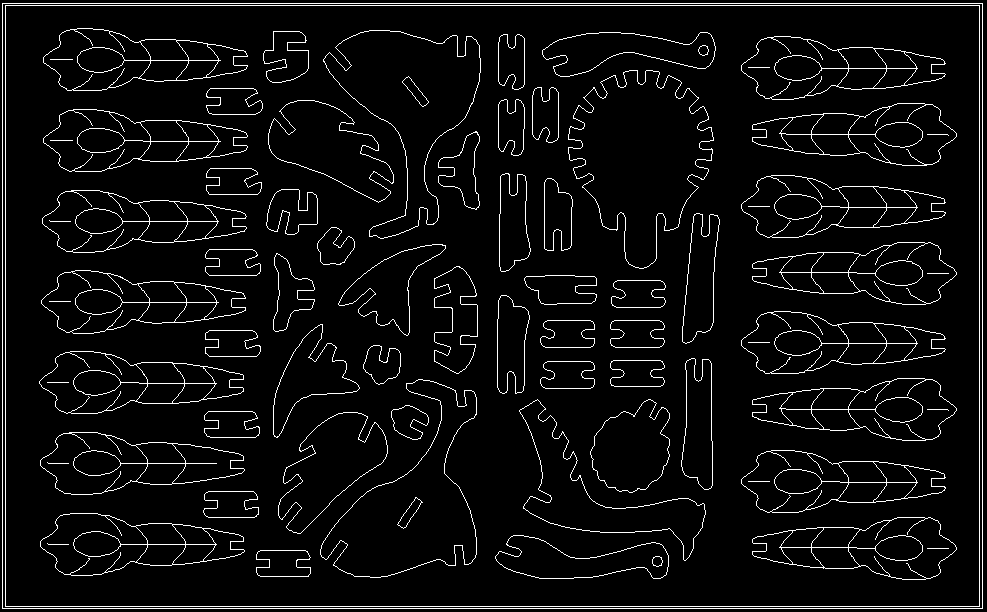

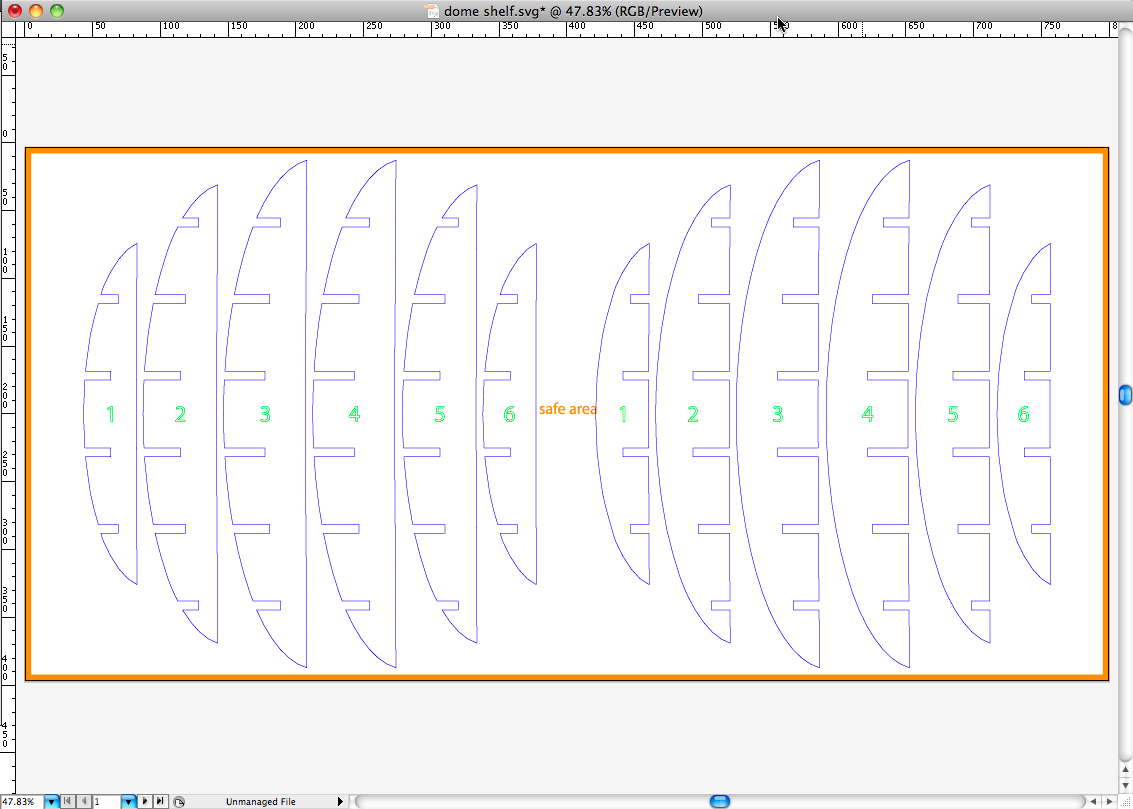

1. Vector-Based Templates: Created using vector graphics software, these templates define the paths that the laser will follow to cut the material.

2. Raster-Based Templates: Generated from bitmap images, these templates provide a more detailed representation of the object to be cut.

3. Parametric Templates: These templates use mathematical equations to define the shape and dimensions of the object, allowing for easy customization.

H3: Material Considerations for 3D Laser Cutting

1. Thickness: The thickness of the material will determine the power and speed settings of the laser.

3D laser cut templates have revolutionized the fabrication industry, enabling the creation of intricate and precise three-dimensional objects from various materials. These templates guide laser cutting machines to cut and shape materials with unparalleled accuracy and efficiency, opening up a world of possibilities for designers, engineers, and manufacturers.

- 3d Laser Cut Wood 3D Laser Cut Wood: Unlocking Intricate Designs And Precision Craftsmanship

- 3d Laser Cutting Files 3D Laser Cutting Files: A Comprehensive Guide For Design And Fabrication

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- 3d Laser Cut Puzzle 3D Laser Cut Puzzles: An Intriguing World Of Precision And Creativity

- 3d Cutting Design 3D Cutting Design: Unleashing Precision And Creativity In Manufacturing

H1: Advantages of 3D Laser Cut Templates

1. Precision and Accuracy: Laser cutting guided by 3D templates delivers unmatched precision, resulting in components with tight tolerances and smooth surfaces.

2. Design Flexibility: Templates allow for the creation of complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods.

3. Material Versatility: 3D laser cut templates can be used with a wide range of materials, including metals, plastics, wood, and composites.

4. Cost-Effectiveness: Laser cutting templates reduce waste and streamline production processes, leading to significant cost savings.

2. Reflectivity: Reflective materials can interfere with laser cutting, requiring special techniques or coatings.

3. Thermal Conductivity: Materials with high thermal conductivity may require slower cutting speeds to prevent heat buildup.

H4: Applications of 3D Laser Cut Templates

1. Industrial Manufacturing: Aerospace, automotive, and medical industries rely heavily on 3D laser cut templates for high-precision components.

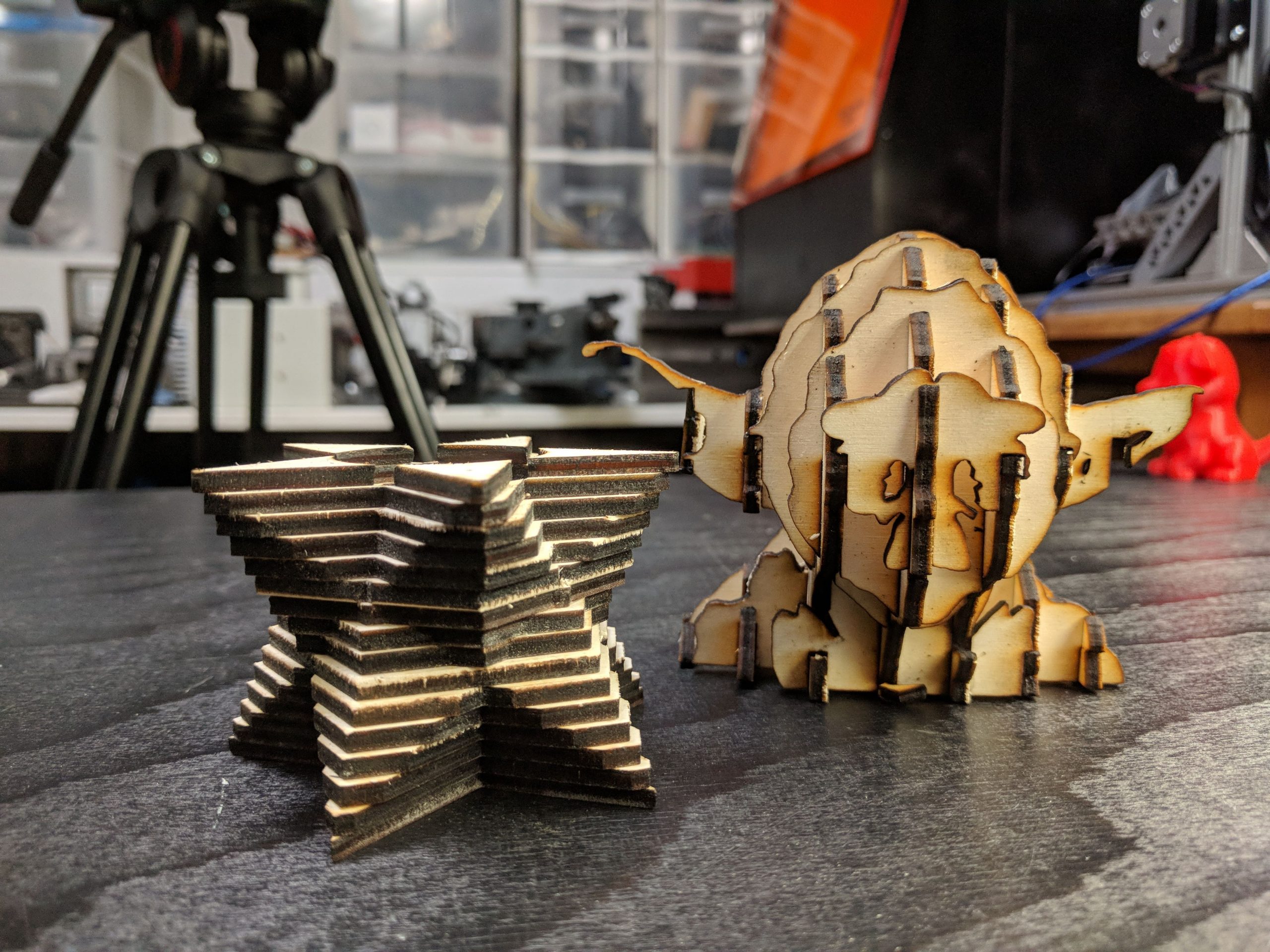

2. Architecture and Design: Templates are used to create intricate building facades, furniture, and decorative elements.

3. Arts and Crafts: Laser cut templates enable the creation of unique and personalized items for home decor, jewelry, and more.

H5: Design Considerations for 3D Laser Cut Templates

1. Kerf Width: The width of the laser beam will affect the size and accuracy of the cut.

2. Overburn: Excessive laser power can burn or melt the material around the cut.

3. Material Shrinkage: Some materials may shrink or warp during laser cutting, which should be accounted for in the template design.

H6: Conclusion

3D laser cut templates are a powerful tool that has transformed the fabrication industry. Their precision, flexibility, and cost-effectiveness make them an ideal solution for a wide range of applications. By understanding the advantages, types, and design considerations associated with 3D laser cut templates, designers and manufacturers can unlock the full potential of this technology.

FAQs

1. What is the difference between vector and raster templates?

Vector templates use mathematical equations to define lines and shapes, while raster templates are based on bitmap images.

2. What materials can be cut with 3D laser cut templates?

3D laser cut templates can be used with a wide range of materials, including metals, plastics, wood, and composites.

3. How can I create my own 3D laser cut templates?

You can use vector graphics software or online tools to create your own 3D laser cut templates.

4. What are the benefits of using parametric templates?

Parametric templates allow for easy customization of the shape and dimensions of the object to be cut.

5. What are the challenges associated with laser cutting reflective materials?

Reflective materials can interfere with laser cutting, requiring special techniques or coatings to achieve optimal results.