3D Laser Cut Wood: The Ultimate Guide to Precision and Creativity

Introduction

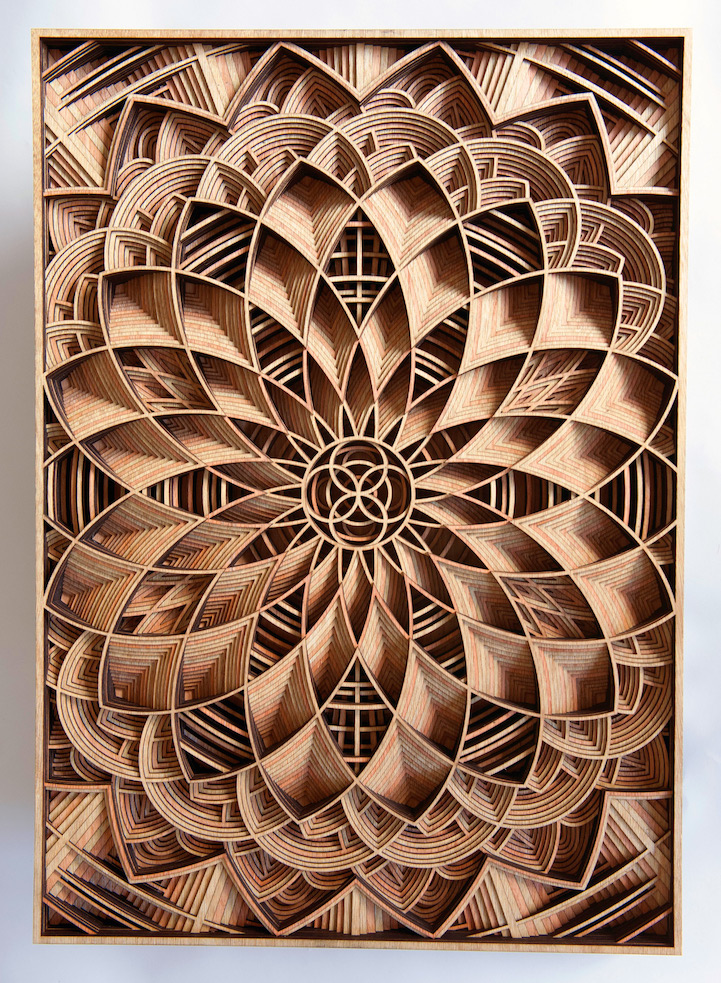

3D laser cut wood is a revolutionary technology that has transformed the way we create intricate and unique wooden objects. By utilizing a high-powered laser to precisely cut and engrave wood, 3D laser cutting allows for the production of complex designs with unmatched accuracy and detail. In this comprehensive guide, we will delve into the world of 3D laser cut wood, exploring its capabilities, benefits, applications, and the factors that influence its quality.

Table of Content

- 1 3D Laser Cut Wood: The Ultimate Guide to Precision and Creativity

- 1.1 Introduction

- 2 H1: Understanding 3D Laser Cut Wood

- 2.2 H2: Types of 3D Laser Cut Wood

- 2.3 H2: Benefits of 3D Laser Cut Wood

- 3 H1: Understanding 3D Laser Cut Wood

- 3.4 H2: The Technology Behind Laser Cutting

- 3.5 H2: Types of 3D Laser Cut Wood

- 4 H1: Applications of 3D Laser Cut Wood

- 4.6 H2: Home Decor and Furniture

- 4.7 H2: Product Design and Prototyping

- 4.8 H2: Art and Craft

- 5 H1: Factors Influencing the Quality of 3D Laser Cut Wood

- 5.9 H2: Laser Power and Focus

- 5.10 H2: Wood Type and Grain

- 5.11 H2: Cutting Speed and Feed Rate

- 6 H1: Conclusion

- 7 FAQs

- 7.12 Q: What is the difference between 3D laser cut wood and traditional woodworking?

- 7.13 Q: Can 3D laser cut wood be used to create objects of any size?

- 7.14 Q: Is 3D laser cut wood suitable for outdoor use?

H1: Understanding 3D Laser Cut Wood

3D laser cutting involves using a computer-controlled laser to vaporize or melt specific areas of wood, creating precise cuts and engravings. The laser beam is typically generated by a carbon dioxide (CO2) or fiber laser and directed onto the wood surface through a series of mirrors and lenses. The laser’s intensity and focus can be adjusted to achieve the desired depth and precision of the cut.

H2: Types of 3D Laser Cut Wood

3D laser cut wood can be classified into two main types:

- Flat Cut: Involves cutting and engraving a single layer of wood, resulting in a 2D design.

- Stacked Cut: Involves cutting and engraving multiple layers of wood and stacking them together, creating a 3D object.

H2: Benefits of 3D Laser Cut Wood

- Precision: Laser cutting provides unmatched precision, allowing for the creation of complex designs with intricate details.

- 3d Fabric Laser Cut 3D Fabric Laser Cutting: A Revolutionary Textile Innovation

- 3d Laser Cut Bee 3D Laser Cut Bee: A Buzzing Masterpiece Of Precision And Creativity

- 3d Laser Cut Sticker 3D Laser Cut Stickers: Elevate Your Brand With Dimension And Impact

- 3d Laser Cut Butterfly 3D Laser Cut Butterfly: An Intricate And Delicate Work Of Art

- 3d Laser Cut Invitations 3D Laser Cut Invitations: Elevate Your Events With Intricate Beauty

- Versatility: 3D laser cutting can be used on a wide range of wood species, including hardwoods, softwoods, and plywood.

- Customization: Laser cutting enables the production of highly customized objects, tailored to specific requirements and preferences.

- Speed: Laser cutting is a relatively fast process, making it suitable for large-scale production or prototyping.

- Automation: Laser cutting can be automated, reducing labor costs and increasing efficiency.

3D laser cut wood is a revolutionary technology that has transformed the way we create intricate and unique wooden objects. By utilizing a high-powered laser to precisely cut and engrave wood, 3D laser cutting allows for the production of complex designs with unmatched accuracy and detail. In this comprehensive guide, we will delve into the world of 3D laser cut wood, exploring its capabilities, benefits, applications, and the factors that influence its quality.

H1: Understanding 3D Laser Cut Wood

H2: The Technology Behind Laser Cutting

3D laser cutting involves using a computer-controlled laser to vaporize or melt specific areas of wood, creating precise cuts and engravings. The laser beam is typically generated by a carbon dioxide (CO2) or fiber laser and directed onto the wood surface through a series of mirrors and lenses. The laser’s intensity and focus can be adjusted to achieve the desired depth and precision of the cut.

H2: Types of 3D Laser Cut Wood

3D laser cut wood can be classified into two main types:

H1: Applications of 3D Laser Cut Wood

H2: Home Decor and Furniture

3D laser cut wood is widely used in home decor and furniture, creating unique and stylish pieces such as:

- Wall art and sculptures

- Furniture accents and embellishments

- Lamps and lighting fixtures

- Custom-designed tables and chairs

H2: Product Design and Prototyping

3D laser cut wood is ideal for product design and prototyping, allowing for the rapid creation of functional and visually appealing prototypes. It is commonly used for:

- Architectural models

- Product packaging

- Industrial prototypes

- Custom toys and games

H2: Art and Craft

3D laser cut wood has become a popular medium for artists and crafters, enabling them to create intricate and personalized works of art. It is used for:

- Wood carvings and sculptures

- Jewelry and accessories

- Custom gifts and keepsakes

- Home decor and embellishments

H1: Factors Influencing the Quality of 3D Laser Cut Wood

H2: Laser Power and Focus

The power and focus of the laser significantly impact the quality of the cut. Higher power lasers can cut thicker wood and produce deeper engravings, while a sharper focus results in more precise cuts.

H2: Wood Type and Grain

The type of wood and its grain orientation can influence the cut quality. Softwoods, such as pine, tend to cut more easily than hardwoods, such as oak. Cutting against the grain can result in rougher edges.

H2: Cutting Speed and Feed Rate

The speed at which the laser moves across the wood and the feed rate, which controls the speed of the wood feed, affect the cut quality. Faster speeds can lead to rougher cuts, while slower speeds produce smoother and more precise cuts.

H1: Conclusion

3D laser cut wood is a versatile and transformative technology that has revolutionized the way we create wooden objects. Its unmatched precision, customization capabilities, and wide range of applications make it a valuable tool for designers, manufacturers, artists, and crafters alike. By understanding the technology, benefits, and factors that influence the quality of 3D laser cut wood, users can harness its potential to create stunning and innovative designs.

FAQs

Q: What is the difference between 3D laser cut wood and traditional woodworking?

A: Traditional woodworking involves manually cutting and shaping wood using tools such as saws, chisels, and planes. 3D laser cutting uses a high-powered laser to precisely cut and engrave wood, resulting in unmatched precision and detail.

Q: Can 3D laser cut wood be used to create objects of any size?

A: The size of objects that can be created using 3D laser cut wood is limited by the size of the laser cutter and the thickness of the wood. However, many laser cutters can accommodate large sheets of wood, allowing for the production of large-scale objects.

Q: Is 3D laser cut wood suitable for outdoor use?

A: Yes, 3D laser cut wood can be suitable for outdoor use if it is properly treated with protective finishes or coatings. However, it is important to note that wood is a natural material and may be susceptible to weathering and deterioration over time.

:max_bytes(150000):strip_icc()/__opt__aboutcom__coeus__resources__content_migration__treehugger__images__2018__03__laser-cut-wood-art-gabriel-schama-11-ced43bfa2bd6419da1c569254654ffcd.jpg)