3D Laser Cut Wood Projects: A Comprehensive Guide to Crafting Unique and Intricate Designs

Introduction

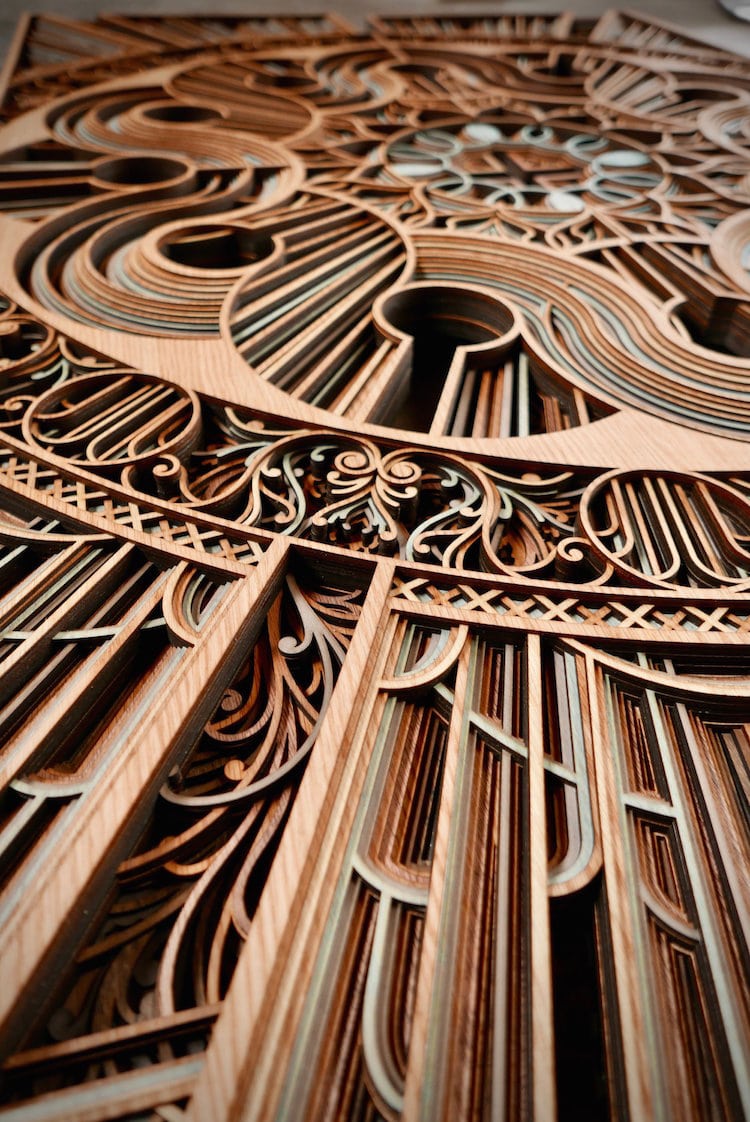

Laser cutting has revolutionized the world of woodworking, empowering hobbyists and professionals alike to create stunning three-dimensional (3D) objects from wood. With the precision and versatility of laser technology, the possibilities for 3D laser cut wood projects are endless, from intricate sculptures to functional home décor. This comprehensive guide will delve into the techniques, materials, and design considerations involved in laser cutting 3D wood projects, providing you with the knowledge and inspiration to embark on your own creative journey.

Table of Content

- 1 3D Laser Cut Wood Projects: A Comprehensive Guide to Crafting Unique and Intricate Designs

- 1.1 Introduction

- 2 Understanding the Laser Cutting Process

- 2.2 Factors Affecting Laser Cutting Quality

- 3 Choosing the Right Wood for 3D Laser Cutting

- 4 Understanding the Laser Cutting Process

- 4.3 Factors Affecting Laser Cutting Quality

- 4.4 Considerations for Selecting Wood Thickness

- 5 Designing 3D Laser Cut Wood Projects

- 5.5 Tips for Designing 3D Wood Projects

- 6 Cutting and Assembling 3D Laser Cut Wood Projects

- 6.6 Laser Cutting Process

- 6.7 Assembly Techniques

- 7 Creative Applications of 3D Laser Cut Wood Projects

- 7.8 Conclusion

- 8 FAQs

- 8.9 Q: What is the best laser cutter for 3D wood projects?

- 8.10 Q: Can I laser cut wood at home?

- 8.11 Q: What are the best ways to finish 3D laser cut wood projects?

- 8.12 Q: How can I learn more about 3D laser cut wood projects?

Understanding the Laser Cutting Process

Factors Affecting Laser Cutting Quality

Several factors influence the quality of laser-cut wood projects:

- Laser power: Higher power lasers can cut thicker materials and achieve finer details.

- Laser wavelength: Different laser wavelengths are absorbed by different materials. CO2 lasers are well-suited for cutting wood.

- Laser beam focus: A focused laser beam produces cleaner cuts and less debris.

- Material type and thickness: Different wood species and thicknesses require different laser settings.

- Cutting speed: The speed at which the laser moves affects the cut quality and edge finish.

Choosing the Right Wood for 3D Laser Cutting

Laser cutting has revolutionized the world of woodworking, empowering hobbyists and professionals alike to create stunning three-dimensional (3D) objects from wood. With the precision and versatility of laser technology, the possibilities for 3D laser cut wood projects are endless, from intricate sculptures to functional home décor. This comprehensive guide will delve into the techniques, materials, and design considerations involved in laser cutting 3D wood projects, providing you with the knowledge and inspiration to embark on your own creative journey.

- 3d Laser Cut Bee 3D Laser Cut Bee: A Buzzing Masterpiece Of Precision And Creativity

- 3d Laser Cut Animal 3D Laser Cut Animal: A Comprehensive Guide To Laser Cutting Animal Designs

- 3d Laser Cutting Files 3D Laser Cutting Files: A Comprehensive Guide For Design And Fabrication

- 3d Laser Cut Car 3D Laser Cut Car: A Comprehensive Guide To Precision And Customization

- 3d Laser Cut Animals 3D Laser Cut Animals: Unlocking A World Of Intricate And Customizable Creations

Understanding the Laser Cutting Process

Laser cutting is a computer-controlled process that uses a high-powered laser beam to cut or engrave materials. For 3D laser cut wood projects, a laser cutter equipped with a CO2 laser is typically used. The laser beam is directed onto the wood surface, vaporizing or burning the material to create precise cuts or etchings.

Factors Affecting Laser Cutting Quality

Several factors influence the quality of laser-cut wood projects:

- Plywood: A versatile and inexpensive material available in various thicknesses and grades.

- MDF (Medium-Density Fiberboard): A dense and smooth material suitable for intricate designs.

- Hardwoods: Such as oak, maple, and walnut, offer a rich grain and durability.

- Softwoods: Such as pine and cedar, are lightweight and easy to cut but may have a less refined finish.

- AutoCAD: A professional-grade CAD software used for creating precise designs.

- SketchUp: A user-friendly 3D modeling software suitable for beginners.

- Fusion 360: A cloud-based CAD software with advanced features for complex designs.

- Start with simple designs: Begin with straightforward projects to gain confidence and master the basics.

- Consider the grain direction: The wood grain affects the cut quality and the overall aesthetic of the project.

- Design for assembly: Ensure that the individual components fit together seamlessly.

- Use tabs and slots: These features facilitate assembly and provide structural stability.

- Optimize for laser cutting: Avoid excessive details or sharp corners that may compromise cut quality.

- Prepare the laser cutter: Calibrate the laser and set the appropriate cutting parameters for the chosen wood.

- Secure the wood: Clamp the wood firmly to the cutting bed to prevent movement during cutting.

- Run the laser cutter: Initiate the cutting process and monitor the progress to ensure accuracy.

- Dry fit: Assemble the components without glue to ensure proper fit.

- Glue assembly: Use wood glue to bond the components together. Apply glue sparingly to avoid excess squeeze-out.

- Clamping: Clamp the assembled project to secure the joints while the glue dries.

- Sanding and finishing: Smooth any rough edges and apply a finish, such as paint or stain, to enhance the appearance and durability.

- Home décor: Wall art, sculptures, lamps, and furniture

- Toys and games: Puzzles, building blocks, and dollhouses

- Jewelry and accessories: Earrings, pendants, and bracelets

- Industrial and architectural applications: Prototyping, signage, and model making

- Musical instruments: Guitar bodies, drums, and wind instruments

The choice of wood for 3D laser cutting depends on the desired project outcome. Some suitable wood species include:

Considerations for Selecting Wood Thickness

The thickness of the wood affects the cutting depth and the overall structural integrity of the project. For intricate designs, thinner wood is preferred to achieve finer details. For sturdier projects, thicker wood provides greater strength and durability.

Designing 3D Laser Cut Wood Projects

Designing 3D laser cut wood projects requires a combination of technical skills and creativity. Several software programs are available for creating 3D models, including:

Tips for Designing 3D Wood Projects

Cutting and Assembling 3D Laser Cut Wood Projects

Laser Cutting Process

Assembly Techniques

Creative Applications of 3D Laser Cut Wood Projects

The possibilities for 3D laser cut wood projects are vast, including:

Conclusion

3D laser cut wood projects offer a unique and versatile medium for expressing creativity and crafting functional objects. By understanding the laser cutting process, choosing the right wood, designing effectively, and mastering assembly techniques, you can create stunning and intricate 3D wood creations. Whether you are a hobbyist or a professional, the possibilities are endless with 3D laser cut wood projects.

FAQs

Q: What is the best laser cutter for 3D wood projects?

A: The best laser cutter depends on your specific needs and budget. Consider factors such as laser power, bed size, and software compatibility.

Q: Can I laser cut wood at home?

A: Yes, small laser cutters are available for home use. However, ensure proper ventilation and follow safety precautions.

Q: What are the best ways to finish 3D laser cut wood projects?

A: Sanding, painting, staining, and varnishing are common finishing techniques. Choose a finish that enhances the appearance and durability of the project.

Q: How can I learn more about 3D laser cut wood projects?

A: Online resources, workshops, and books provide valuable information on design, cutting techniques, and assembly.