3D Laser Cutting: A Comprehensive Guide

Introduction

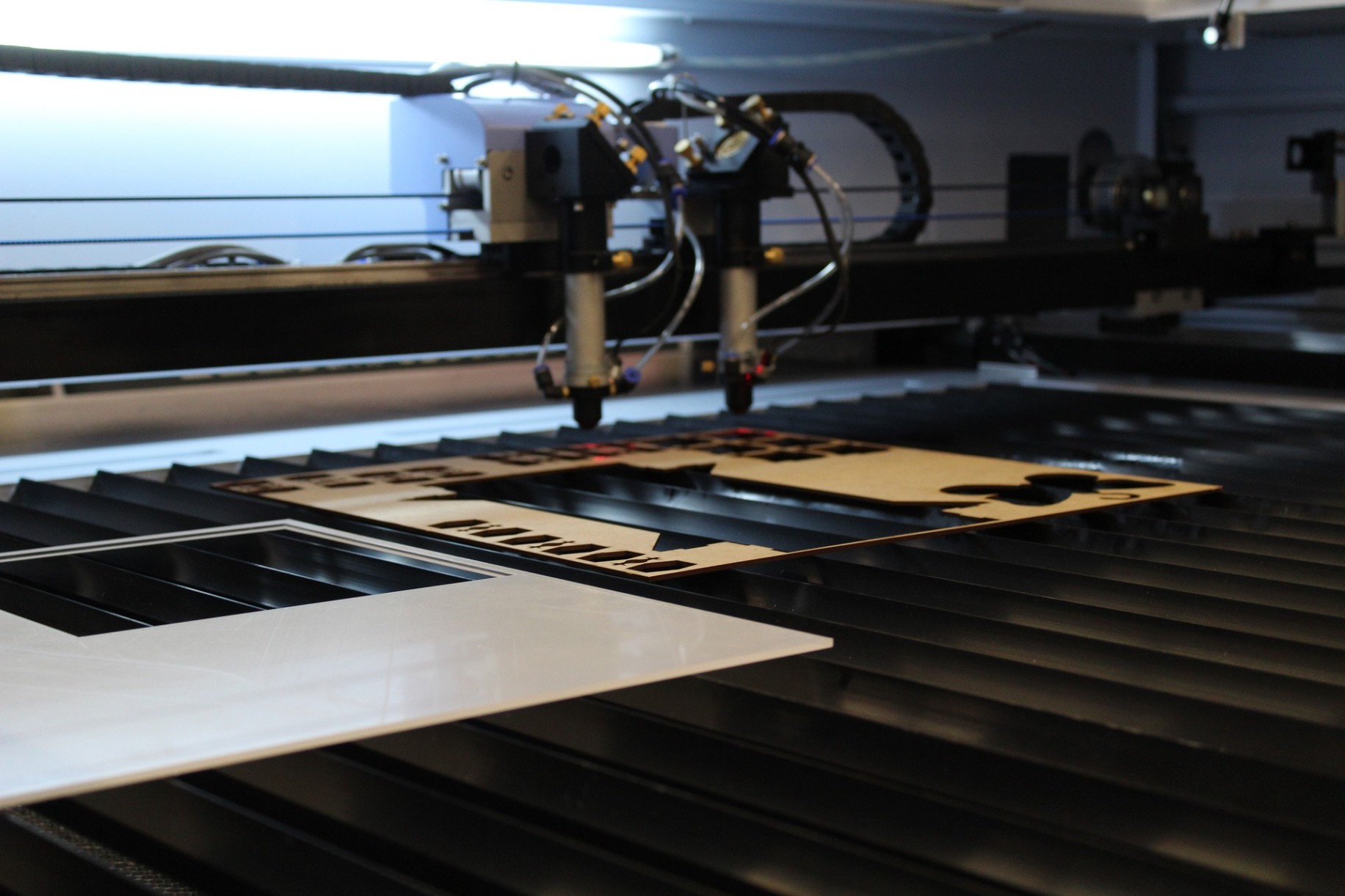

3D laser cutting is a revolutionary manufacturing process that utilizes a high-powered laser beam to cut complex shapes and designs into three-dimensional materials. This advanced technology offers unparalleled precision, speed, and versatility, making it a preferred choice for a wide range of industries.

Table of Content

How 3D Laser Cutting Works

Advantages of 3D Laser Cutting

1. High Precision and Accuracy:

3D laser cutting delivers exceptional precision, enabling the creation of intricate designs with tight tolerances. This level of accuracy is crucial for applications requiring precise dimensions and complex shapes.

2. Fast and Efficient:

Laser cutting is a rapid process, significantly reducing production time compared to traditional methods. The high-powered laser beam quickly vaporizes the material, minimizing heat-affected zones and ensuring fast turnaround times.

3. Versatile Material Compatibility:

3D laser cutting can process a wide range of materials, including metals, plastics, wood, ceramics, and composites. This versatility makes it suitable for various applications across different industries.

4. Intricate Designs and Complex Geometries:

The ability to cut complex shapes and geometries is a key advantage of 3D laser cutting. This technology allows for the creation of intricate designs that would be impossible to achieve with traditional cutting methods.

Applications of 3D Laser Cutting

3D laser cutting is a revolutionary manufacturing process that utilizes a high-powered laser beam to cut complex shapes and designs into three-dimensional materials. This advanced technology offers unparalleled precision, speed, and versatility, making it a preferred choice for a wide range of industries.

- Sculpteo Laser Cutting Sculpteo Laser Cutting: A Comprehensive Guide To Precision Manufacturing

- 3d Printing And Laser Cutting 3D Printing And Laser Cutting: A Comprehensive Guide

- Sketchup Laser Cutting H1: Unleashing The Power Of SketchUp Laser Cutting: A Comprehensive Guide

- Sketchup For Laser Cutting SketchUp For Laser Cutting: A Comprehensive Guide

- 3d Tube Cutting 3D Tube Cutting: A Comprehensive Guide To Advanced Manufacturing

How 3D Laser Cutting Works

The fundamental principle behind 3D laser cutting involves directing a focused laser beam onto the workpiece surface. The intense heat generated by the laser beam melts, vaporizes, or burns away the material, creating precise cuts and intricate geometries. The laser beam is controlled by a computer-aided design (CAD) system, ensuring accuracy and repeatability.

Advantages of 3D Laser Cutting

1. High Precision and Accuracy:

3D laser cutting delivers exceptional precision, enabling the creation of intricate designs with tight tolerances. This level of accuracy is crucial for applications requiring precise dimensions and complex shapes.

3D laser cutting has found widespread applications in numerous industries, including:

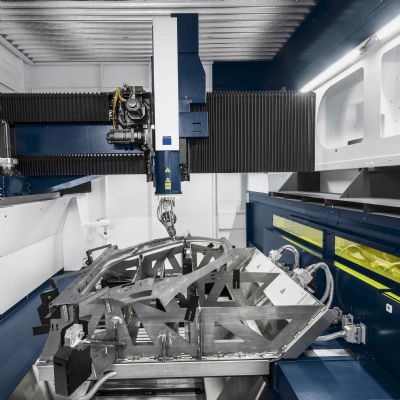

1. Aerospace:

Precision cutting of aircraft components, such as turbine blades, airfoils, and structural parts.

2. Automotive:

Manufacturing of complex automotive parts, including dashboards, interior trim, and exhaust systems.

3. Medical:

Production of medical devices, such as surgical instruments, implants, and prosthetics.

4. Electronics:

Fabrication of printed circuit boards (PCBs), connectors, and electronic components.

Factors Affecting 3D Laser Cutting

Several factors influence the effectiveness and quality of 3D laser cutting:

1. Laser Power:

The power of the laser beam determines the cutting speed, depth, and precision. Higher laser power results in faster cutting and deeper cuts.

2. Material Properties:

The material being cut affects the laser parameters required for optimal results. Different materials have varying thermal properties and require specific laser settings.

3. Cutting Speed:

The cutting speed must be optimized to balance precision and efficiency. Too high a speed can lead to rough cuts, while too low a speed can result in excessive heat-affected zones.

4. Gas Assist:

Inert gases, such as nitrogen or argon, are often used to assist in the cutting process. These gases help to remove debris, prevent oxidation, and improve cut quality.

Conclusion

3D laser cutting is a transformative technology that has revolutionized manufacturing processes across various industries. Its exceptional precision, speed, and versatility make it an ideal solution for cutting complex shapes and intricate geometries. By understanding the principles, advantages, and applications of 3D laser cutting, manufacturers can leverage this advanced technology to achieve superior results and enhance their competitiveness.

FAQs

1. What is the difference between 3D laser cutting and traditional cutting methods?

3D laser cutting utilizes a high-powered laser beam to melt, vaporize, or burn away material, while traditional cutting methods rely on mechanical or abrasive processes to remove material.

2. Can 3D laser cutting be used on any material?

3D laser cutting is compatible with a wide range of materials, including metals, plastics, wood, ceramics, and composites. However, the laser parameters and cutting strategy must be adjusted to suit the specific material properties.

3. How does 3D laser cutting ensure precision and accuracy?

The laser beam is controlled by a CAD system, which ensures precise positioning and repeatable cuts. Additionally, the laser’s focused beam minimizes heat-affected zones, resulting in high-quality cuts with tight tolerances.

4. What are the advantages of using 3D laser cutting in the automotive industry?

3D laser cutting allows for the production of complex automotive parts with precise dimensions and intricate designs. This technology reduces manufacturing time, improves part quality, and enables the creation of innovative and lightweight components.

5. How does 3D laser cutting contribute to advancements in the medical field?

3D laser cutting is used to fabricate medical devices with exceptional precision and accuracy. This technology enables the production of complex implants, surgical instruments, and prosthetics, improving patient outcomes and advancing surgical techniques.