3D Laser Cutting Adelaide: Revolutionizing Fabrication in South Australia

Introduction

3D laser cutting has emerged as a transformative technology in the manufacturing industry, offering unparalleled precision, speed, and versatility. Adelaide, the vibrant capital of South Australia, has embraced this innovative technology, boasting a thriving ecosystem of 3D laser cutting service providers. In this comprehensive guide, we will delve into the world of 3D laser cutting Adelaide, exploring its capabilities, benefits, and applications.

Table of Content

- 1 3D Laser Cutting Adelaide: Revolutionizing Fabrication in South Australia

- 1.1 Introduction

- 2 Understanding 3D Laser Cutting

- 2.2 How It Works

- 2.3 Materials Compatibility

- 3 Understanding 3D Laser Cutting

- 3.4 How It Works

- 3.5 Materials Compatibility

- 4 Benefits of 3D Laser Cutting Adelaide

- 4.6 Precision and Accuracy

- 4.7 Speed and Efficiency

- 4.8 Design Flexibility

- 4.9 Material Versatility

- 4.10 Applications of 3D Laser Cutting Adelaide

- 4.11 Manufacturing

- 4.12 Signage and Display

- 4.13 Art and Design

- 4.14 Medical and Dental

- 5 Choosing a 3D Laser Cutting Service Provider

- 5.15 Experience and Expertise

- 5.16 Equipment and Capabilities

- 5.17 Quality Control

- 5.18 Customer Service

- 6 Conclusion

- 7 FAQs

Understanding 3D Laser Cutting

How It Works

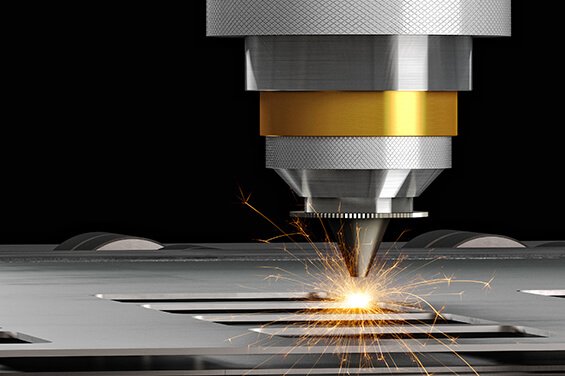

The laser beam is generated by a laser source and directed through a series of mirrors and lenses. The beam is then focused onto the workpiece, where it melts or vaporizes the material along its path. By precisely controlling the laser’s movement, complex 3D shapes can be created.

Materials Compatibility

3D laser cutting is compatible with a wide range of materials, including:

- Metals (e.g., stainless steel, aluminum, titanium)

- Plastics (e.g., acrylic, polycarbonate, ABS)

- Wood

- Composites

- Ceramics

- 3d Laser Cut Wall Art 3D Laser Cut Wall Art: A Stunning Addition To Your Home Decor

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

- 3d Laser Cut Art 3D Laser Cut Art: Unlocking A World Of Dimensional Creativity

- Snapmaker Cnc Cutting Wood Snapmaker CNC: Unleashing Precision And Versatility For Woodworking

- Simple 3d Laser Cut Simple 3D Laser Cut: A Comprehensive Guide

3D laser cutting has emerged as a transformative technology in the manufacturing industry, offering unparalleled precision, speed, and versatility. Adelaide, the vibrant capital of South Australia, has embraced this innovative technology, boasting a thriving ecosystem of 3D laser cutting service providers. In this comprehensive guide, we will delve into the world of 3D laser cutting Adelaide, exploring its capabilities, benefits, and applications.

Understanding 3D Laser Cutting

3D laser cutting is a fabrication process that utilizes a focused laser beam to cut complex shapes and designs into various materials. Unlike traditional cutting methods, 3D laser cutting allows for intricate cuts with exceptional accuracy and minimal material waste.

How It Works

The laser beam is generated by a laser source and directed through a series of mirrors and lenses. The beam is then focused onto the workpiece, where it melts or vaporizes the material along its path. By precisely controlling the laser’s movement, complex 3D shapes can be created.

Materials Compatibility

Benefits of 3D Laser Cutting Adelaide

Precision and Accuracy

3D laser cutting offers exceptional precision and accuracy, allowing for the creation of intricate designs with tight tolerances. The laser beam can achieve cutting widths as narrow as 0.005 inches, ensuring precise and repeatable results.

Speed and Efficiency

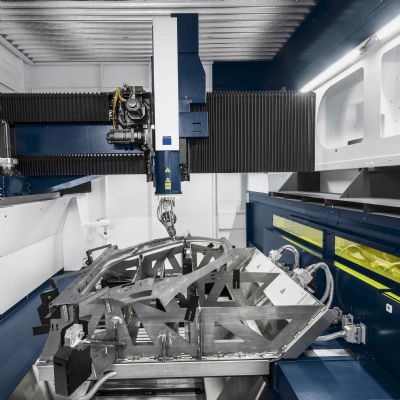

Laser cutting is a high-speed process, significantly reducing production times compared to traditional methods. The laser’s ability to cut complex shapes without the need for tool changes further enhances efficiency.

Design Flexibility

3D laser cutting enables the creation of complex and unconventional designs that would be impossible or impractical to achieve with other cutting techniques. This design flexibility opens up new possibilities for product innovation.

Material Versatility

The wide range of compatible materials makes 3D laser cutting suitable for various applications across different industries. From intricate metal parts to delicate wood carvings, the technology accommodates diverse material requirements.

Applications of 3D Laser Cutting Adelaide

Manufacturing

3D laser cutting is widely used in the manufacturing industry for applications such as:

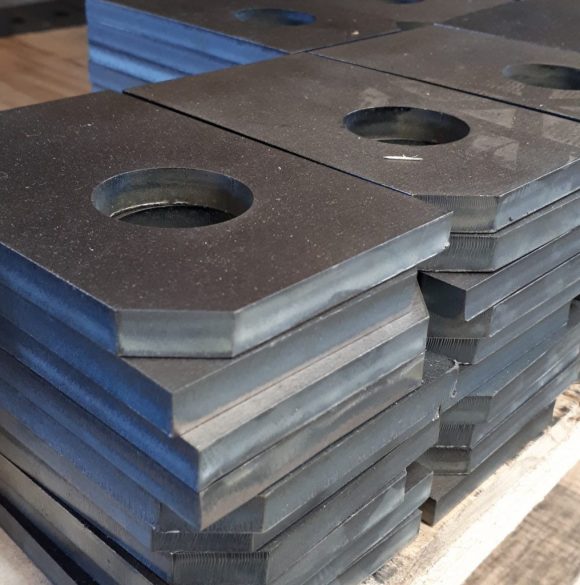

- Precision metal fabrication

- Prototype development

- Tool and mold making

- Aerospace components

Signage and Display

The technology is ideal for creating eye-catching signage, display stands, and architectural elements with intricate designs.

Art and Design

3D laser cutting has become a popular medium for artistic expression, allowing artists to create unique sculptures, jewelry, and decorative pieces.

Medical and Dental

The precision and accuracy of 3D laser cutting make it suitable for applications in the medical and dental fields, such as surgical instrument fabrication and dental implant production.

Choosing a 3D Laser Cutting Service Provider

When selecting a 3D laser cutting service provider in Adelaide, consider the following factors:

Experience and Expertise

Look for a provider with a proven track record of delivering high-quality laser cutting services.

Equipment and Capabilities

Ensure that the provider has the latest 3D laser cutting equipment and can meet your specific material and design requirements.

Quality Control

Inquire about the provider’s quality control measures to guarantee the precision and accuracy of their work.

Customer Service

Choose a provider that offers responsive and reliable customer service to address your inquiries and provide ongoing support.

Conclusion

3D laser cutting Adelaide has transformed fabrication in South Australia, offering businesses and individuals unparalleled capabilities for creating complex and innovative designs with precision, speed, and versatility. By leveraging the expertise of reputable 3D laser cutting service providers, you can harness the power of this technology to drive innovation, enhance productivity, and bring your creative visions to life.

FAQs

Q: What is the maximum cutting thickness for 3D laser cutting?

A: Cutting thickness varies depending on the material and laser power, but typically ranges from 0.005 inches to 1 inch.

Q: Can 3D laser cutting be used for engraving?

A: Yes, 3D laser cutting can be used for engraving by adjusting the laser parameters to create shallow cuts or markings.

Q: Is 3D laser cutting safe?

A: 3D laser cutting is a safe process when operated by trained professionals. Safety precautions include wearing protective gear and ensuring proper ventilation.

Q: How much does 3D laser cutting cost?

A: Costs vary depending on the complexity of the design, material, and cutting time. Contact service providers for specific quotes.

Q: Can 3D laser cutting create 3D objects?

A: While 3D laser cutting can create complex shapes, it does not produce true 3D objects. For 3D object creation, consider 3D printing or other additive manufacturing techniques.