3D Laser Cutting Design: Revolutionizing Manufacturing and Creativity

Introduction

3D laser cutting design has emerged as a game-changer in the manufacturing and creative industries, enabling the production of intricate and complex designs with unprecedented precision and efficiency. This article delves into the world of 3D laser cutting design, exploring its capabilities, applications, and the benefits it offers.

Table of Content

- 1 3D Laser Cutting Design: Revolutionizing Manufacturing and Creativity

- 1.1 Introduction

- 1.2 H1: Understanding 3D Laser Cutting Design

- 1.3 H2: Advantages of 3D Laser Cutting

- 1.4 H1: Applications of 3D Laser Cutting Design

- 1.5 H1: Understanding 3D Laser Cutting Design

- 1.6 H2: The Laser Cutting Process

- 1.7 H2: Advantages of 3D Laser Cutting

- 1.8 H2: Manufacturing

- 1.9 H2: Creative Industries

- 1.10 H1: Benefits of 3D Laser Cutting Design

- 1.11 H2: Increased Productivity

- 1.12 H2: Improved Quality

- 1.13 H2: Reduced Material Waste

- 1.14 H2: Design Innovation

- 1.15 H1: Conclusion

- 1.16 FAQs

H1: Understanding 3D Laser Cutting Design

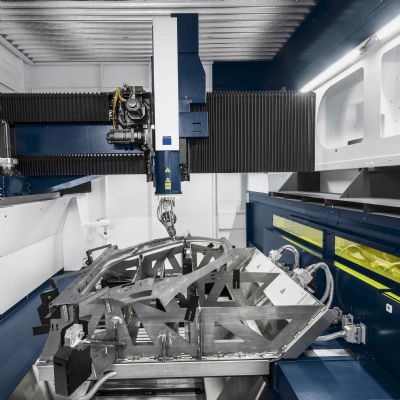

3D laser cutting involves directing a focused laser beam onto a workpiece, melting or vaporizing the material to create intricate designs. The laser beam is guided by a computer-controlled system, allowing for precise and automated cutting.

H2: Advantages of 3D Laser Cutting

- Precision: Laser cutting delivers unmatched precision, producing sharp edges and intricate details.

- Speed: The laser beam cuts through materials at high speeds, increasing production efficiency.

- Versatility: 3D laser cutting can work with a wide range of materials, including metals, plastics, and wood.

- Cost-Effectiveness: Laser cutting reduces waste and minimizes the need for manual labor, resulting in cost savings.

- Design Complexity: The computer-controlled system allows for the creation of complex and intricate designs that are difficult or impossible to achieve through traditional methods.

H1: Applications of 3D Laser Cutting Design

3D laser cutting design has emerged as a game-changer in the manufacturing and creative industries, enabling the production of intricate and complex designs with unprecedented precision and efficiency. This article delves into the world of 3D laser cutting design, exploring its capabilities, applications, and the benefits it offers.

- 3d Printers And Laser Cutters 3D Printers And Laser Cutters: A Comprehensive Guide

- 3d Laser Cutting Metal 3D Laser Cutting Metal: A Comprehensive Guide

- Mazak 3d Laser Cutting Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

- 3d Laser Cut 3D Laser Cutting: A Comprehensive Guide

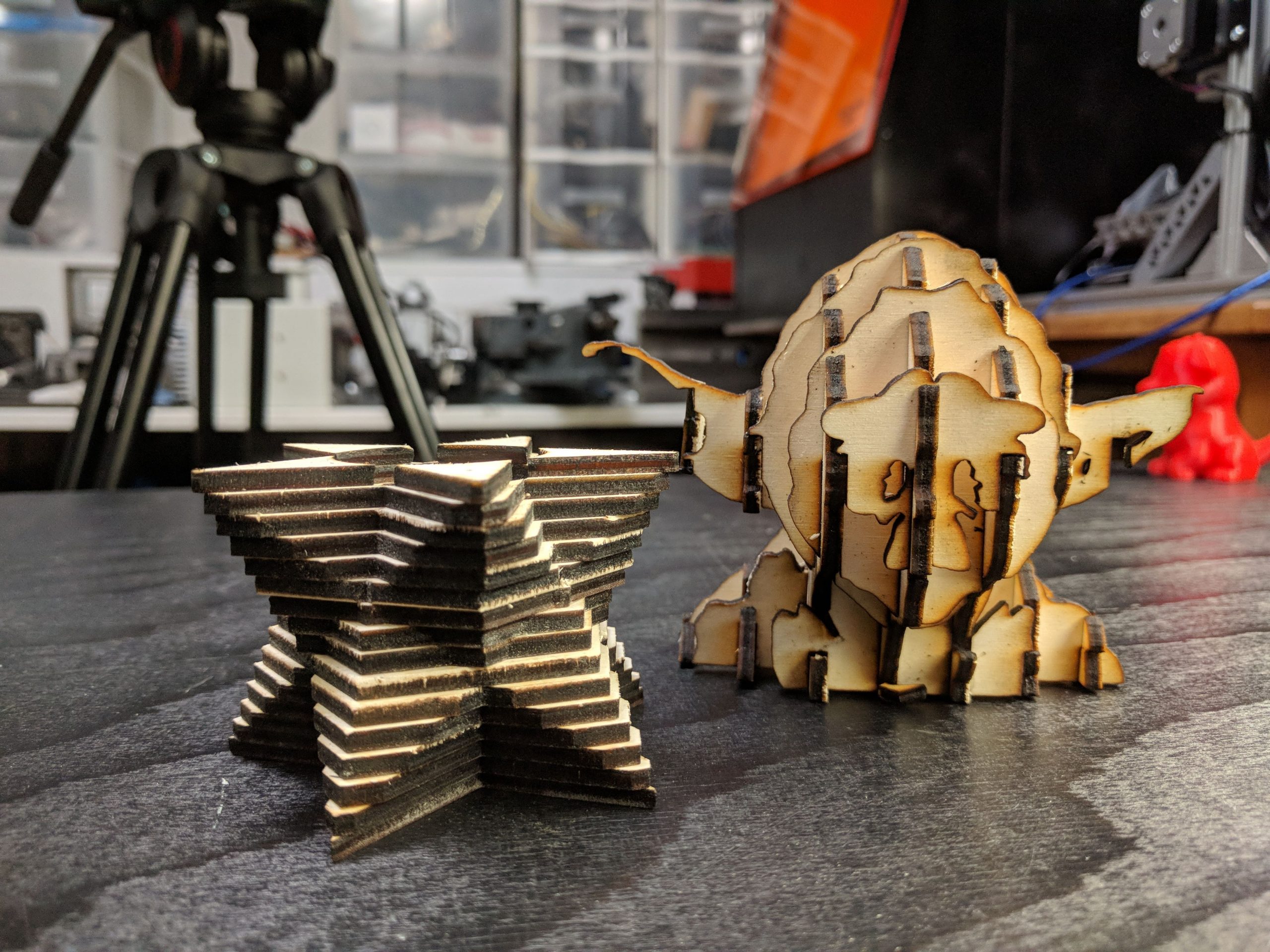

- 3d Laser Cut Wooden Puzzles 3D Laser Cut Wooden Puzzles: A Guide To Intricate And Enchanting Creations

H1: Understanding 3D Laser Cutting Design

H2: The Laser Cutting Process

3D laser cutting involves directing a focused laser beam onto a workpiece, melting or vaporizing the material to create intricate designs. The laser beam is guided by a computer-controlled system, allowing for precise and automated cutting.

H2: Advantages of 3D Laser Cutting

- Automotive Parts: Creating precision components for vehicles, such as engine parts and body panels.

- Aerospace: Manufacturing lightweight and aerodynamic parts for aircraft and spacecraft.

- Medical Devices: Producing surgical instruments, implants, and other medical devices with intricate geometries.

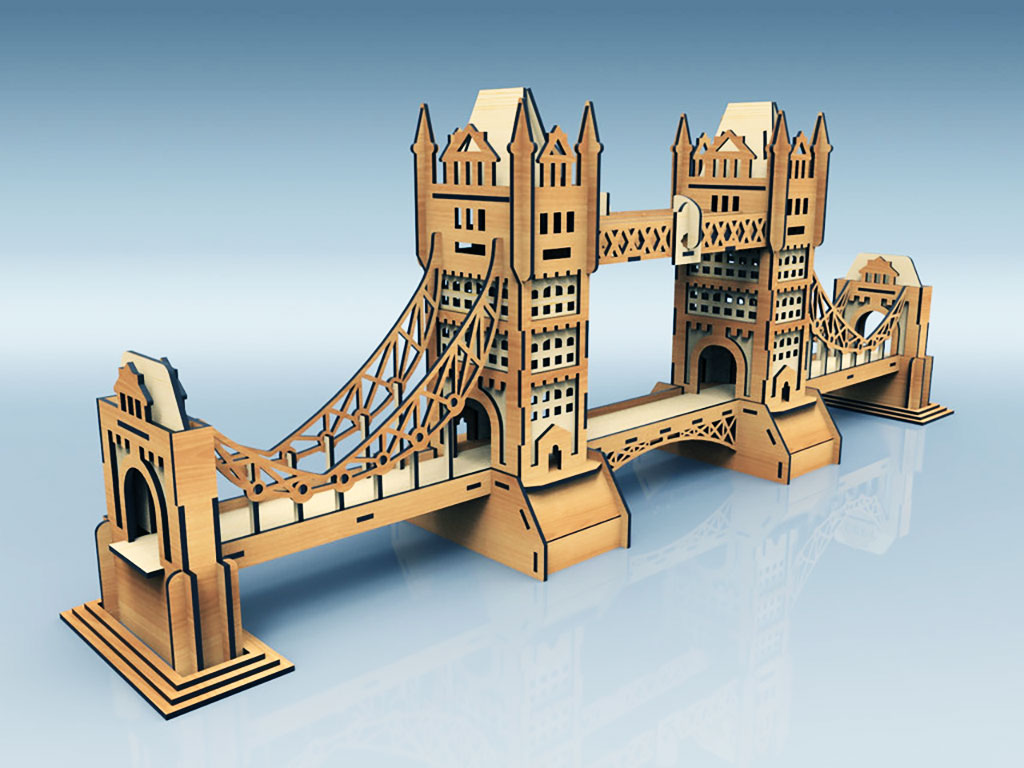

- Architecture: Designing and fabricating custom architectural elements, such as facades, railings, and sculptures.

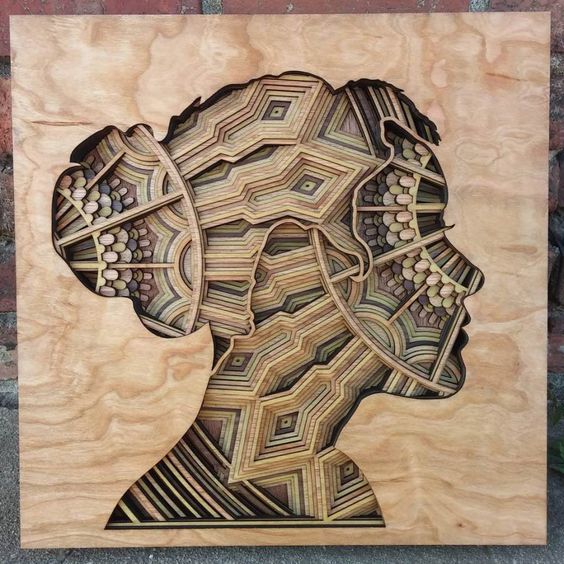

- Jewelry: Creating intricate jewelry designs with fine details and smooth surfaces.

- Product Design: Developing innovative and functional products with unique shapes and textures.

H2: Manufacturing

H2: Creative Industries

H1: Benefits of 3D Laser Cutting Design

H2: Increased Productivity

The automated nature of laser cutting allows for faster production times and increased output compared to traditional methods.

H2: Improved Quality

Laser cutting provides high-quality cuts with minimal burrs or distortions, resulting in superior product aesthetics and performance.

H2: Reduced Material Waste

The precise cutting process minimizes material waste, reducing production costs and promoting sustainability.

H2: Design Innovation

3D laser cutting enables the creation of complex and innovative designs that were previously not possible, pushing the boundaries of creativity and product development.

H1: Conclusion

3D laser cutting design has transformed the manufacturing and creative industries by offering precision, efficiency, versatility, and cost-effectiveness. Its applications extend across various sectors, from automotive to aerospace to architecture and jewelry. By embracing the power of 3D laser cutting, businesses and designers can unlock new possibilities, enhance productivity, and create innovative products that redefine industry standards.

FAQs

Q: What materials can be cut with 3D laser cutting?

A: 3D laser cutting can work with a wide range of materials, including metals (e.g., steel, aluminum), plastics (e.g., acrylic, polycarbonate), and wood (e.g., plywood, MDF).

Q: How does 3D laser cutting differ from traditional cutting methods?

A: 3D laser cutting uses a focused laser beam to melt or vaporize material, while traditional methods (e.g., milling, waterjet cutting) use mechanical force or a high-pressure water stream. Laser cutting offers greater precision, speed, and design flexibility.

Q: What are the safety considerations for 3D laser cutting?

A: Laser cutting involves high-energy laser beams, so it is essential to follow safety protocols, such as wearing protective eyewear, using proper ventilation, and ensuring proper training for operators.