3D Laser Cutting Machine: A Comprehensive Guide

Introduction

3D laser cutting machines are revolutionizing manufacturing industries, offering unparalleled precision, speed, and versatility. These machines use high-powered lasers to cut complex shapes and intricate designs into a wide range of materials, including metals, plastics, and wood. This article provides an in-depth overview of 3D laser cutting machines, their capabilities, benefits, and applications.

Table of Content

- 1 3D Laser Cutting Machine: A Comprehensive Guide

- 1.1 Introduction

- 2 H1: Understanding 3D Laser Cutting Technology

- 2.2 H3: Types of 3D Laser Cutting Machines

- 3 H1: Capabilities and Benefits of 3D Laser Cutting

- 3.3 H2: Precision and Accuracy

- 4 H1: Understanding 3D Laser Cutting Technology

- 4.4 H2: How Does a 3D Laser Cutting Machine Work?

- 4.5 H3: Types of 3D Laser Cutting Machines

- 4.6 H3: Speed and Efficiency

- 4.7 H4: Versatility and Flexibility

- 5 H1: Applications of 3D Laser Cutting

- 5.8 H2: Industrial Manufacturing

- 5.9 H3: Prototyping and Product Development

- 5.10 H4: Art and Design

- 6 H1: Factors to Consider When Choosing a 3D Laser Cutting Machine

- 6.11 H2: Material Thickness and Type

- 6.12 H3: Cutting Speed and Accuracy

- 6.13 H4: Budget and Return on Investment

- 7 Conclusion

- 8 FAQs

H1: Understanding 3D Laser Cutting Technology

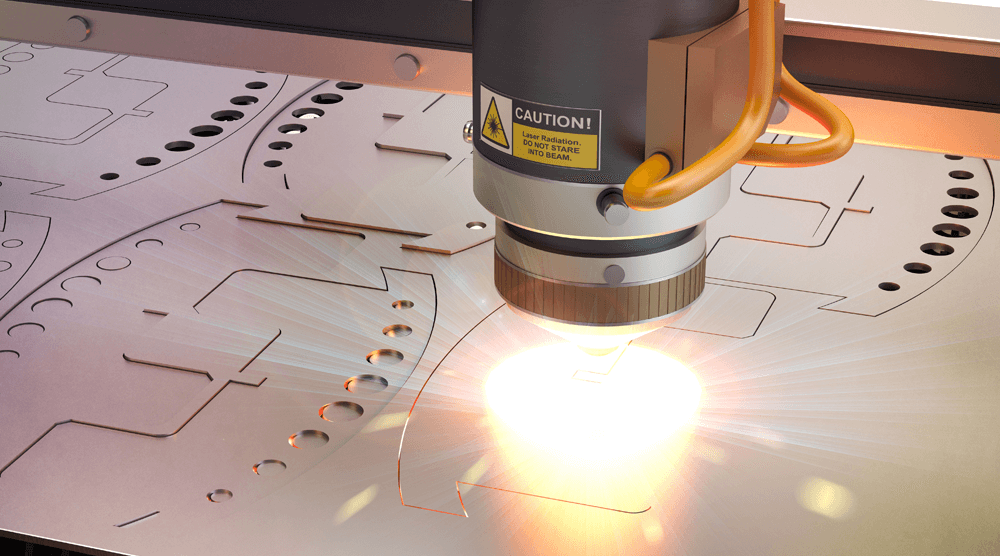

3D laser cutting machines use a focused beam of laser light to melt or vaporize material, creating precise cuts. The laser beam is guided by a computer-controlled system, which follows a predefined path to cut the desired shape. The process is highly automated, ensuring consistent and repeatable results.

H3: Types of 3D Laser Cutting Machines

There are two main types of 3D laser cutting machines:

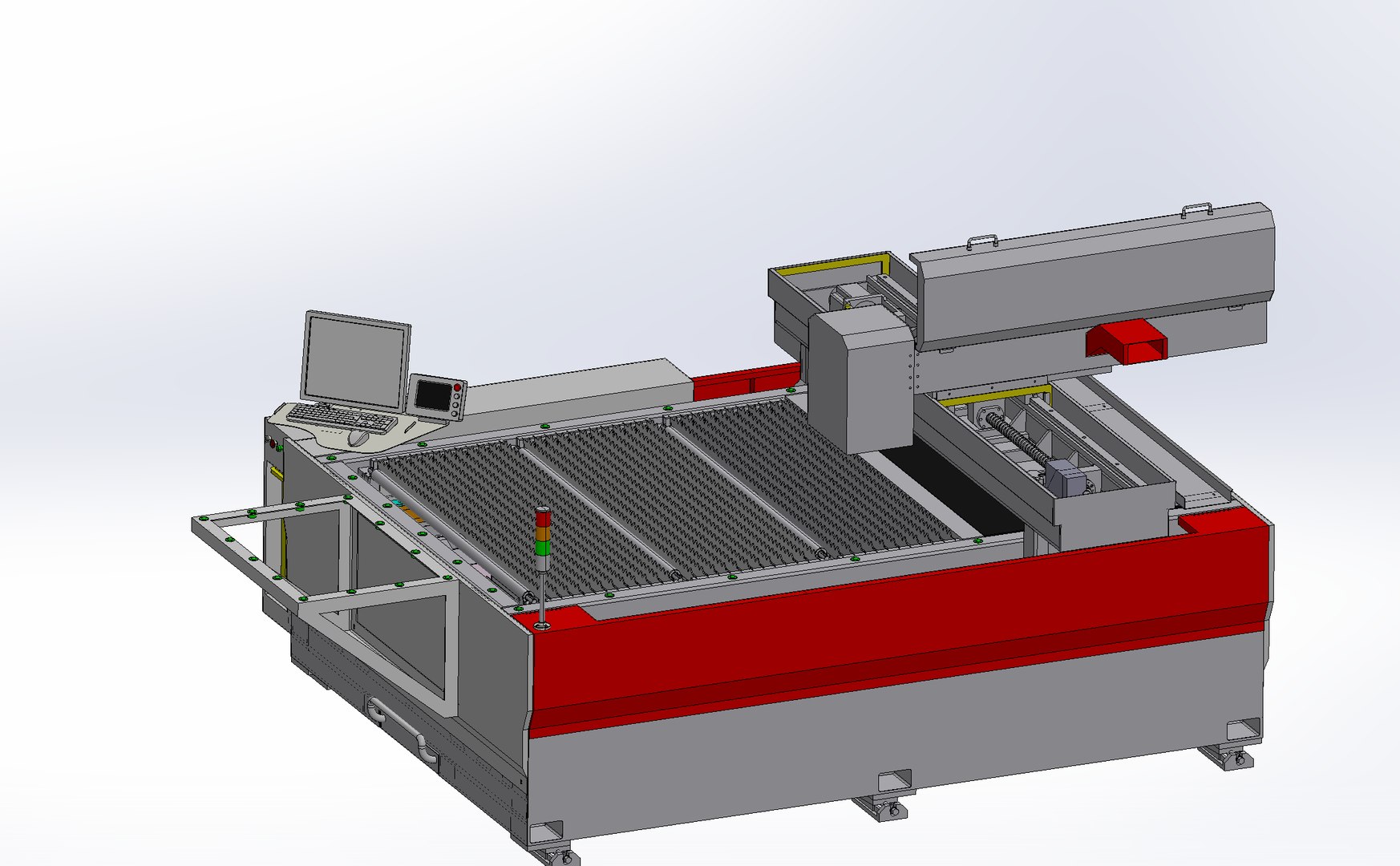

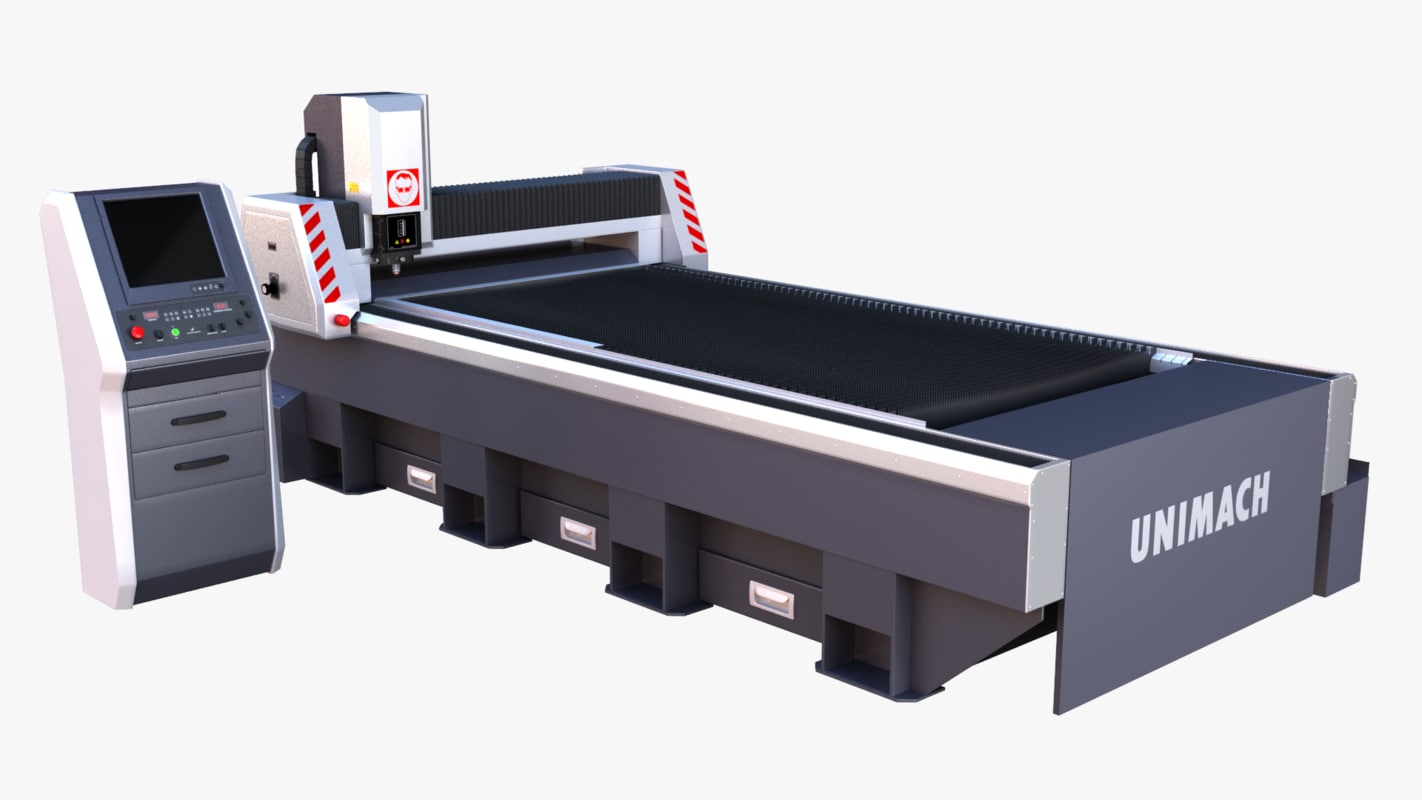

- Galvo-based machines: These machines use a high-speed galvanometer mirror to direct the laser beam. They are suitable for cutting thin materials at high speeds.

- Gantry-based machines: These machines use a gantry system to move the laser head over the material. They are more versatile and can cut thicker materials than galvo-based machines.

H1: Capabilities and Benefits of 3D Laser Cutting

H2: Precision and Accuracy

3D laser cutting machines offer exceptional precision and accuracy, with tolerances of up to ±0.005 mm. This makes them ideal for cutting intricate shapes and complex geometries.

3D laser cutting machines are revolutionizing manufacturing industries, offering unparalleled precision, speed, and versatility. These machines use high-powered lasers to cut complex shapes and intricate designs into a wide range of materials, including metals, plastics, and wood. This article provides an in-depth overview of 3D laser cutting machines, their capabilities, benefits, and applications.

- 3d 6 Axis Laser Cutting 3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

- Mazak 3d Laser Cutting Mazak 3D Laser Cutting: Revolutionizing Metal Fabrication

- Snapmaker Laser Cutting Guide Snapmaker Laser Cutting Guide: A Comprehensive Walkthrough

H1: Understanding 3D Laser Cutting Technology

H2: How Does a 3D Laser Cutting Machine Work?

3D laser cutting machines use a focused beam of laser light to melt or vaporize material, creating precise cuts. The laser beam is guided by a computer-controlled system, which follows a predefined path to cut the desired shape. The process is highly automated, ensuring consistent and repeatable results.

H3: Types of 3D Laser Cutting Machines

There are two main types of 3D laser cutting machines:

H3: Speed and Efficiency

These machines can cut materials at speeds of up to several meters per minute, significantly improving production efficiency. The automated nature of the process further reduces labor costs.

H4: Versatility and Flexibility

3D laser cutting machines can cut a wide range of materials, including metals, plastics, wood, and ceramics. This versatility makes them suitable for various industries and applications.

H1: Applications of 3D Laser Cutting

H2: Industrial Manufacturing

3D laser cutting is widely used in industrial manufacturing for:

- Cutting sheet metal for automotive, aerospace, and medical devices

- Fabricating complex components for machinery and equipment

- Creating intricate patterns in textiles and leather goods

H3: Prototyping and Product Development

These machines are invaluable for prototyping and product development, allowing designers and engineers to quickly create physical models and iterate on their designs.

H4: Art and Design

3D laser cutting is also gaining popularity in art and design, enabling artists to create unique sculptures, jewelry, and decorative pieces.

H1: Factors to Consider When Choosing a 3D Laser Cutting Machine

H2: Material Thickness and Type

Consider the thickness and type of materials you will be cutting. Different machines have different capabilities in terms of material thickness and compatibility.

H3: Cutting Speed and Accuracy

Determine the required cutting speed and accuracy for your applications. Machines with higher speeds and precision come at a higher cost.

H4: Budget and Return on Investment

Establish a budget and calculate the potential return on investment (ROI) based on the increased efficiency and reduced labor costs.

Conclusion

3D laser cutting machines are transformative tools that offer unparalleled precision, speed, and versatility. They are revolutionizing manufacturing industries and enabling new possibilities in prototyping, product development, and art and design. By carefully considering the capabilities and factors discussed in this article, you can choose the right 3D laser cutting machine to meet your specific needs and unlock the full potential of this advanced technology.

FAQs

Q: What are the safety precautions when operating a 3D laser cutting machine?

A: Laser cutting machines emit high-powered laser beams, so it is crucial to wear appropriate safety glasses and protective clothing. The machine should be operated in a well-ventilated area, and the laser beam should never be directed towards people or reflective surfaces.

Q: How do I maintain a 3D laser cutting machine?

A: Regular maintenance is essential to ensure optimal performance and longevity. This includes cleaning the laser head, checking the optical alignment, and replacing consumables such as lenses and nozzles.

Q: What are the latest advancements in 3D laser cutting technology?

A: Recent advancements include the development of fiber lasers, which offer higher power and efficiency, and the integration of artificial intelligence (AI) for process optimization and quality control.