3D Laser Cutting Metal: A Comprehensive Guide

Introduction

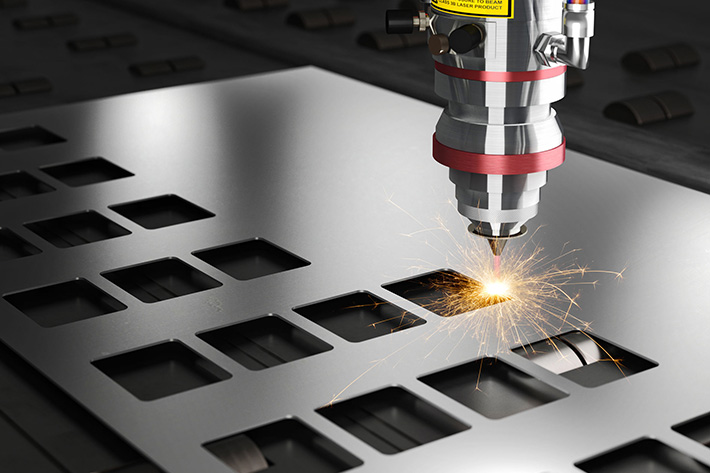

3D laser cutting metal is a revolutionary manufacturing process that has transformed the metalworking industry. This technology enables the precise and efficient cutting of complex three-dimensional shapes from a wide range of metals. In this article, we will delve into the world of 3D laser cutting metal, exploring its capabilities, applications, benefits, and key considerations.

Table of Content

- 1 3D Laser Cutting Metal: A Comprehensive Guide

- 1.1 Introduction

- 1.2 How Does 3D Laser Cutting Metal Work?

- 1.3 Capabilities of 3D Laser Cutting Metal

- 1.4 Applications of 3D Laser Cutting Metal

- 1.5 How Does 3D Laser Cutting Metal Work?

- 1.6 Capabilities of 3D Laser Cutting Metal

- 1.7 Benefits of 3D Laser Cutting Metal

- 1.8 Key Considerations for 3D Laser Cutting Metal

- 1.9 Conclusion

- 1.10 Frequently Asked Questions

How Does 3D Laser Cutting Metal Work?

Capabilities of 3D Laser Cutting Metal

3D laser cutting metal offers a range of capabilities that set it apart from traditional cutting methods:

- Complex Shape Cutting: 3D laser cutting can create highly intricate and complex shapes with precise contours and smooth surfaces.

- Precise Cutting Accuracy: The laser beam delivers exceptional cutting accuracy, ensuring tight tolerances and consistent results.

- Minimal Material Waste: Laser cutting minimizes material waste by vaporizing the material along the cutting path, resulting in efficient material utilization.

- Wide Range of Metals: 3D laser cutting is compatible with a wide variety of metals, including steel, stainless steel, aluminum, and titanium.

Applications of 3D Laser Cutting Metal

3D laser cutting metal finds applications in various industries, including:

3D laser cutting metal is a revolutionary manufacturing process that has transformed the metalworking industry. This technology enables the precise and efficient cutting of complex three-dimensional shapes from a wide range of metals. In this article, we will delve into the world of 3D laser cutting metal, exploring its capabilities, applications, benefits, and key considerations.

- 3d Laser Cutter Projects 3D Laser Cutter Projects: Unleashing Creativity And Precision

- Free 3d Laser Cutting Files Free 3D Laser Cutting Files: Elevate Your Crafting And Design Projects

- 3d Laser Cutting Machine Company 3D Laser Cutting Machine: Revolutionizing Fabrication

- 3d Laser Cutting Services 3D Laser Cutting Services: Precision And Innovation In Fabrication

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

How Does 3D Laser Cutting Metal Work?

3D laser cutting metal utilizes a high-power laser beam focused through a computer-controlled system. The laser beam is directed onto the metal surface, melting and vaporizing the material along the programmed cutting path. This process allows for the creation of intricate 3D shapes with high accuracy and minimal material waste.

Capabilities of 3D Laser Cutting Metal

3D laser cutting metal offers a range of capabilities that set it apart from traditional cutting methods:

- Aerospace: Fabrication of complex aircraft components, such as engine parts and airframes.

- Automotive: Production of body panels, exhaust systems, and other automotive components.

- Medical: Manufacturing of surgical instruments, implants, and prosthetics.

- Electronics: Fabrication of intricate circuit boards and electronic components.

- Architecture: Creation of decorative metal panels, sculptures, and architectural elements.

- Increased Production Speed: Laser cutting operates at high speeds, reducing production time and increasing throughput.

- Improved Quality: Laser cutting produces clean and precise cuts, eliminating the need for secondary finishing operations.

- Reduced Labor Costs: Automated laser cutting reduces labor requirements, lowering production costs.

- Enhanced Flexibility: 3D laser cutting can handle complex shapes and different materials, providing greater design freedom.

- Environmental Sustainability: Laser cutting minimizes material waste and reduces energy consumption compared to traditional cutting methods.

- Material Selection: The type of metal being cut will impact the laser cutting parameters and the overall quality of the cut.

- Laser Power and Beam Quality: The laser power and beam quality determine the cutting speed, accuracy, and surface finish.

- Cutting Parameters Optimization: Optimizing cutting parameters, such as speed, power, and gas pressure, is crucial for achieving optimal results.

- Fixturing and Clamping: Proper fixturing and clamping ensure the workpiece is securely held during the cutting process.

- Safety Measures: Laser cutting involves the use of high-power lasers, so proper safety measures, such as protective eyewear and enclosed workspaces, must be in place.

Benefits of 3D Laser Cutting Metal

3D laser cutting metal offers numerous benefits over traditional cutting methods:

Key Considerations for 3D Laser Cutting Metal

Before implementing 3D laser cutting metal in your manufacturing process, several key considerations must be addressed:

Conclusion

3D laser cutting metal is a transformative technology that has revolutionized the metalworking industry. Its ability to create complex shapes with high accuracy and minimal material waste has made it an essential tool for various applications. By understanding the capabilities, benefits, and key considerations of 3D laser cutting metal, manufacturers can leverage this technology to enhance their production processes, improve product quality, and drive innovation.

Frequently Asked Questions

Q: What are the advantages of 3D laser cutting metal over traditional cutting methods?

A: 3D laser cutting offers increased production speed, improved quality, reduced labor costs, enhanced flexibility, and environmental sustainability.

Q: What types of metals can be cut using 3D laser cutting?

A: 3D laser cutting is compatible with a wide range of metals, including steel, stainless steel, aluminum, and titanium.

Q: How does laser power affect the cutting process?

A: Higher laser power enables faster cutting speeds and deeper cuts, but it can also affect the surface finish and heat-affected zone.

Q: What are the key safety considerations for 3D laser cutting metal?

A: Proper safety measures include protective eyewear, enclosed workspaces, and adherence to laser safety protocols.

Q: How can I optimize the cutting parameters for 3D laser cutting metal?

A: Cutting parameters should be optimized based on the material being cut, laser power, and desired cut quality. Experimentation and consultation with experienced professionals are recommended.