3D Laser Cutting Robot: A Comprehensive Guide

Introduction

3D laser cutting robots are revolutionizing the manufacturing industry with their ability to cut complex shapes and designs with precision and speed. This advanced technology offers numerous advantages over traditional cutting methods, making it an indispensable tool for various applications.

Table of Content

- 1 3D Laser Cutting Robot: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H2: Benefits of 3D Laser Cutting Robots

- 1.3 H2: Components of a 3D Laser Cutting Robot

- 1.4 H2: Benefits of 3D Laser Cutting Robots

- 1.5 H2: Applications of 3D Laser Cutting Robots

- 1.6 H2: Factors to Consider When Choosing a 3D Laser Cutting Robot

- 1.7 H2: Conclusion

- 1.8 FAQs

H2: Benefits of 3D Laser Cutting Robots

H2: Components of a 3D Laser Cutting Robot

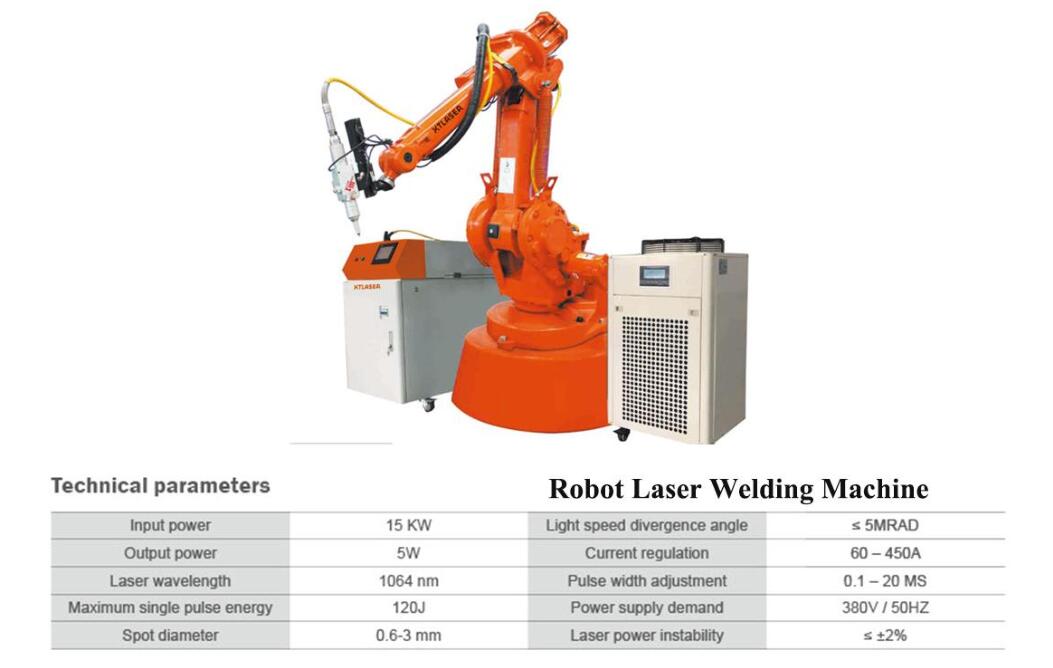

- Laser Source: The laser source generates the high-powered beam that cuts the material. Different laser sources, such as CO2, fiber, and Nd:YAG, are used depending on the material and cutting requirements.

- Optics System: The optics system includes mirrors, lenses, and a beam expander that direct and focus the laser beam onto the workpiece.

- 3d Laser Cut Designs 3D Laser Cut Designs: Unleashing Creativity And Precision

- Laser Cut 3d Shapes Laser Cut 3D Shapes: Transforming Designs Into Tangible Masterpieces

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- 3d Laser Cut Car 3D Laser Cut Car: A Comprehensive Guide To Precision And Customization

- Laser Cut 3d Sculpture Laser Cut 3D Sculpture: Unlocking The Dimensions Of Artistic Expression

- Precision and Accuracy: Laser cutting robots use advanced optics and motion control systems to deliver exceptional precision, producing parts with high accuracy and repeatability.

- Speed and Efficiency: Laser cutting robots operate at high speeds, reducing production time and increasing throughput compared to manual or mechanical cutting methods.

- Flexibility and Versatility: These robots can handle a wide range of materials, including metals, plastics, wood, and ceramics, making them suitable for diverse manufacturing applications.

- Motion Control System: This system controls the movement of the robot’s axes, ensuring precise positioning and cutting of complex geometries.

- Software: The software provides the robot with instructions and controls the cutting process, including laser power, speed, and path planning.

- Automotive Industry: Cutting and shaping of sheet metal components, exhaust systems, and other automotive parts.

- Aerospace Industry: Fabrication of lightweight and complex aircraft parts, such as wing panels and engine components.

- Electronics Industry: Precision cutting of circuit boards, electronic components, and enclosures.

- Medical Industry: Manufacturing of surgical instruments, implants, and prosthetics.

- Jewelry Industry: Intricate cutting of jewelry designs, engraving, and stone setting.

- Material Compatibility: Ensure the robot can handle the materials you intend to cut.

- Cutting Precision and Accuracy: Determine the required level of precision and accuracy for your application.

- Speed and Throughput: Consider the production volume and desired cutting speed.

- Automation Level: Assess the level of automation required, including material handling and part loading/unloading.

- Software and Integration: Ensure compatibility with your existing software and production systems.

3D laser cutting robots are revolutionizing the manufacturing industry with their ability to cut complex shapes and designs with precision and speed. This advanced technology offers numerous advantages over traditional cutting methods, making it an indispensable tool for various applications.

H2: Benefits of 3D Laser Cutting Robots

H2: Applications of 3D Laser Cutting Robots

H2: Factors to Consider When Choosing a 3D Laser Cutting Robot

H2: Conclusion

3D laser cutting robots represent a significant advancement in manufacturing technology, offering unparalleled precision, speed, and versatility. By carefully considering the factors discussed in this guide, manufacturers can select the optimal laser cutting robot to enhance their production capabilities, reduce costs, and drive innovation.

FAQs

Q: What are the maintenance requirements for 3D laser cutting robots?

A: Regular maintenance, including laser source cleaning, optics alignment, and motion system lubrication, is essential to ensure optimal performance and longevity.

Q: Can 3D laser cutting robots be used for prototyping?

A: Yes, 3D laser cutting robots are ideal for prototyping due to their precision and flexibility, allowing for the rapid production of complex prototypes.

Q: What are the safety considerations when using 3D laser cutting robots?

A: Proper safety measures, such as laser safety enclosures, protective eyewear, and proper ventilation, are crucial to protect operators from laser radiation and other hazards.