3D Laser Cutting Trumpf: Revolutionizing the Manufacturing Industry

Introduction

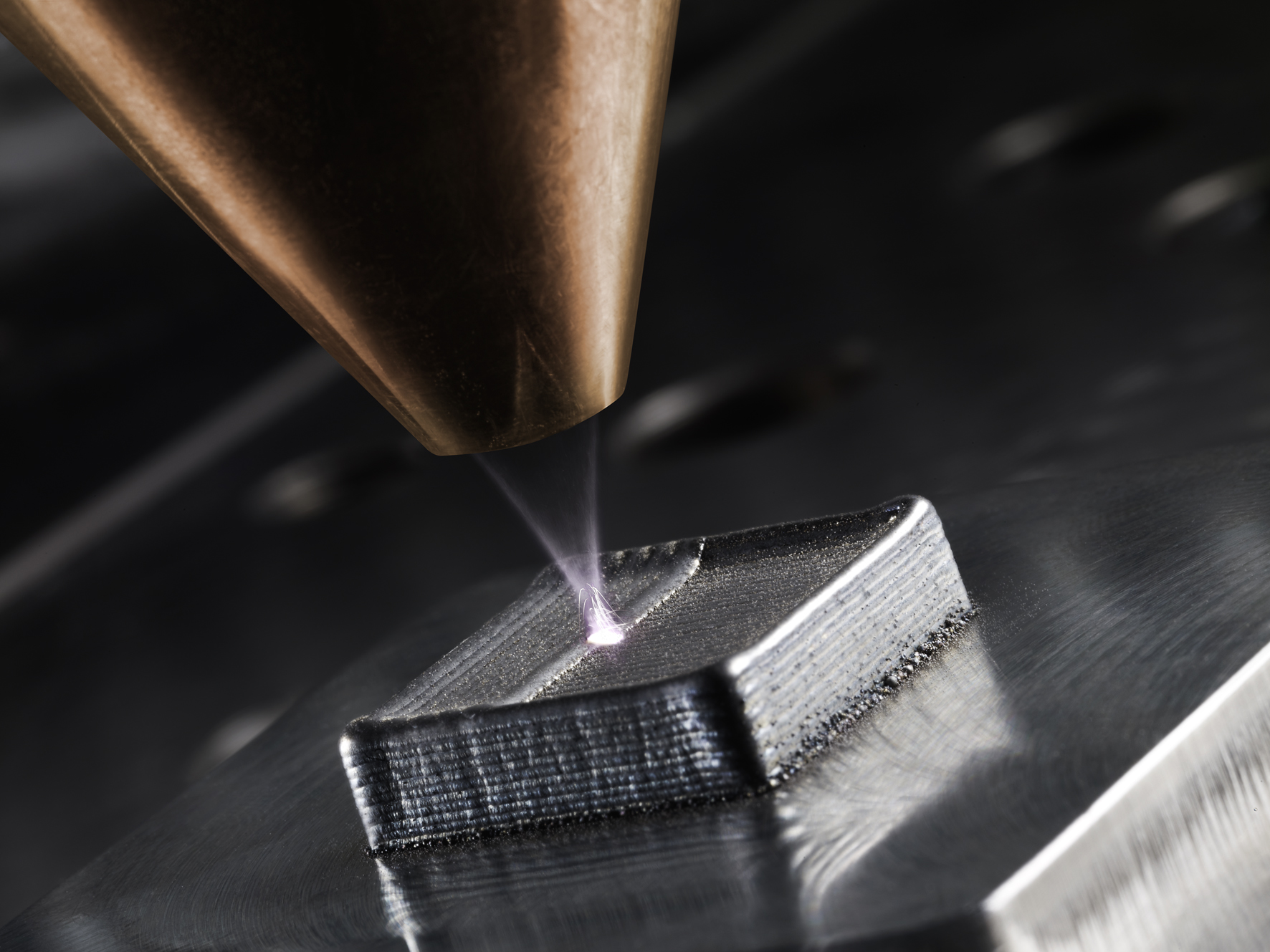

3D laser cutting Trumpf is a groundbreaking technology that has transformed the manufacturing industry. It enables the precise and efficient cutting of complex 3D shapes from various materials, unlocking new possibilities for product design and innovation.

Table of Content

- 1 3D Laser Cutting Trumpf: Revolutionizing the Manufacturing Industry

- 1.1 Introduction

- 1.2 How Does 3D Laser Cutting Trumpf Work?

- 1.3 Key Advantages of 3D Laser Cutting Trumpf

- 1.4 Applications of 3D Laser Cutting Trumpf

- 1.5 How Does 3D Laser Cutting Trumpf Work?

- 1.6 Key Advantages of 3D Laser Cutting Trumpf

- 1.7 Conclusion

- 1.8 FAQs

How Does 3D Laser Cutting Trumpf Work?

Key Advantages of 3D Laser Cutting Trumpf

1. Precision and Accuracy:

3D laser cutting Trumpf delivers unparalleled precision and accuracy, enabling the production of highly detailed and intricate parts with tight tolerances.

2. Versatility:

The technology can cut a wide range of materials, including metals, plastics, and composites, making it suitable for various applications.

3. Speed and Efficiency:

3D laser cutting Trumpf is a fast and efficient process, reducing production time and increasing productivity.

4. Reduced Waste:

The precise nature of the laser cutting process minimizes waste, leading to cost savings and environmental benefits.

Applications of 3D Laser Cutting Trumpf

3D laser cutting Trumpf is a groundbreaking technology that has transformed the manufacturing industry. It enables the precise and efficient cutting of complex 3D shapes from various materials, unlocking new possibilities for product design and innovation.

- Laser Cut 3d Pop Up Cards Laser Cut 3D Pop Up Cards: A Captivating And Interactive Art Form

- 3d Laser Cut Fish 3D Laser Cut Fish: A Comprehensive Guide

- What Is 3d Laser Cutting What Is 3D Laser Cutting?

- 3d Crystal Laser Cutting Machine 3D Crystal Laser Cutting Machine: A Comprehensive Guide

- 3d Laser Cut Objects 3D Laser Cut Objects: Revolutionizing Design And Manufacturing

How Does 3D Laser Cutting Trumpf Work?

The Trumpf 3D laser cutting system utilizes a high-power laser beam directed through a rotating optic to cut through materials. The laser beam melts and vaporizes the material, creating a clean and precise cut. The rotating optic allows for cutting on all sides of the workpiece, resulting in complex 3D shapes.

Key Advantages of 3D Laser Cutting Trumpf

1. Precision and Accuracy:

3D laser cutting Trumpf delivers unparalleled precision and accuracy, enabling the production of highly detailed and intricate parts with tight tolerances.

3D laser cutting Trumpf finds applications in diverse industries, including:

1. Aerospace:

Manufacturing of aircraft components, engine parts, and structural elements.

2. Automotive:

Production of body panels, chassis components, and exhaust systems.

3. Medical:

Fabrication of surgical instruments, implants, and prosthetics.

4. Electronics:

Cutting of printed circuit boards, connectors, and enclosures.

Conclusion

3D laser cutting Trumpf is a game-changing technology that empowers manufacturers to create innovative and complex products with unparalleled precision and efficiency. Its versatility, speed, and reduced waste make it an indispensable tool for various industries. As the technology continues to advance, we can expect even more transformative applications in the years to come.

FAQs

Q1. What is the maximum cutting thickness for 3D laser cutting Trumpf?

A1. The maximum cutting thickness varies depending on the material and machine model but can typically range from 0.1 to 12 mm.

Q2. What are the safety precautions for operating a 3D laser cutting Trumpf machine?

A2. Safety precautions include wearing protective eyewear, gloves, and clothing, ensuring proper ventilation, and following the manufacturer’s operating instructions.

Q3. How can I maintain the quality of cuts made with 3D laser cutting Trumpf?

A3. Regular maintenance, proper calibration, and using high-quality materials can help ensure consistent and high-quality cuts.

Q4. Can 3D laser cutting Trumpf cut through reflective materials?

A4. Yes, 3D laser cutting Trumpf can cut through reflective materials using specialized techniques such as defocusing the laser beam or using a fiber laser with shorter wavelengths.