3D Laser Cutting UK: A Comprehensive Guide to Advanced Manufacturing

Introduction

3D laser cutting is a cutting-edge manufacturing technology that has revolutionized the production of complex and intricate parts. In the UK, this technology is rapidly gaining popularity, offering businesses a competitive edge through increased efficiency, precision, and innovation. This comprehensive guide provides an in-depth exploration of 3D laser cutting UK, including its benefits, applications, and leading providers.

Table of Content

- 1 3D Laser Cutting UK: A Comprehensive Guide to Advanced Manufacturing

- 1.1 Introduction

- 2 Benefits of 3D Laser Cutting

- 2.2 Speed and Efficiency

- 2.3 Versatility

- 2.4 Cost-Effectiveness

- 3 Applications of 3D Laser Cutting

- 3.5 Aerospace

- 4 Benefits of 3D Laser Cutting

- 4.6 Precision and Accuracy

- 4.7 Speed and Efficiency

- 4.8 Automotive

- 4.9 Medical

- 4.10 Electronics

- 4.11 Jewelry and Art

- 5 Leading Providers of 3D Laser Cutting UK

- 5.12 XYZ Laser

- 5.13 Trotec Laser

- 5.14 Epilog Laser

- 6 Conclusion

- 7 FAQs

- 7.15 What materials can be cut with 3D laser cutting?

- 7.16 What are the advantages of 3D laser cutting over traditional methods?

- 7.17 How do I choose the right 3D laser cutting machine for my business?

Benefits of 3D Laser Cutting

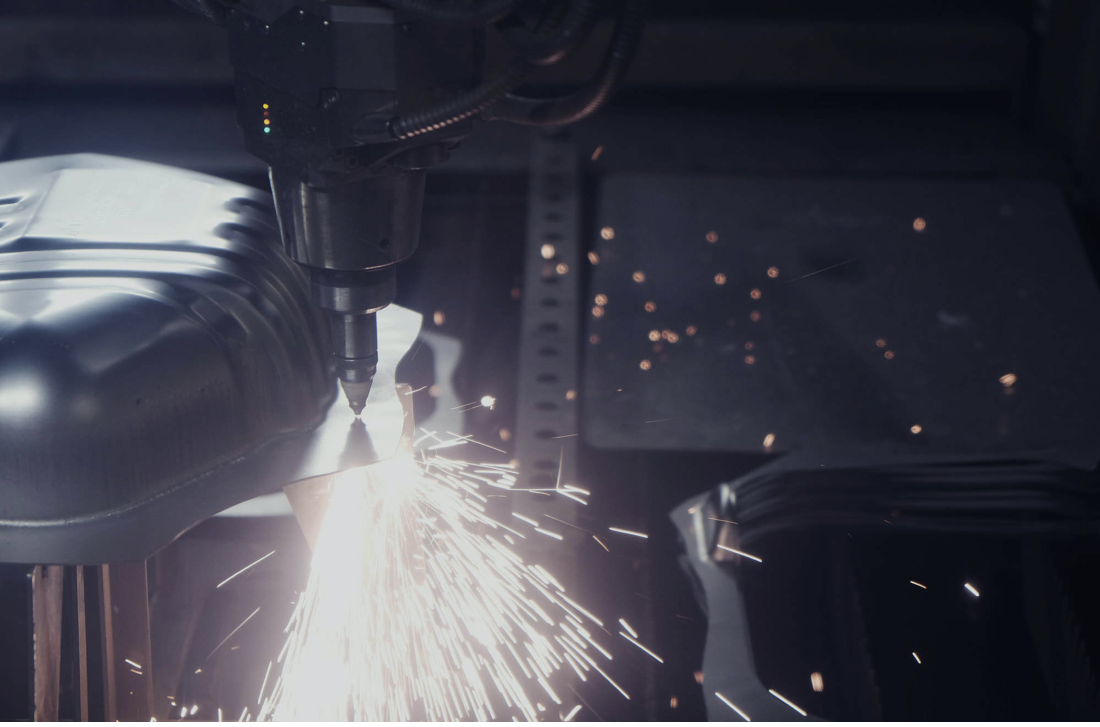

Laser cutting utilizes a highly focused laser beam to precisely cut materials, resulting in clean edges, minimal burrs, and exact dimensions. This level of precision is unmatched by traditional cutting methods, making 3D laser cutting ideal for applications requiring intricate details and tight tolerances.

Speed and Efficiency

3D laser cutting operates at high speeds, significantly reducing production time compared to manual or mechanical cutting. Its automated nature eliminates the need for manual intervention, increasing efficiency and throughput.

Versatility

3D laser cutting is capable of processing a wide range of materials, including metals, plastics, wood, and composites. This versatility allows businesses to produce a diverse range of products from a single machine.

Cost-Effectiveness

While 3D laser cutting equipment can have a higher upfront investment, its long-term cost-effectiveness is evident. The increased precision, speed, and versatility result in reduced material waste, faster production times, and lower labor costs.

Applications of 3D Laser Cutting

Aerospace

3D laser cutting is extensively used in the aerospace industry for the production of lightweight, complex components such as aircraft frames, engine parts, and structural elements.

3D laser cutting is a cutting-edge manufacturing technology that has revolutionized the production of complex and intricate parts. In the UK, this technology is rapidly gaining popularity, offering businesses a competitive edge through increased efficiency, precision, and innovation. This comprehensive guide provides an in-depth exploration of 3D laser cutting UK, including its benefits, applications, and leading providers.

- 3d Laser Cut Wood Models 3D Laser Cut Wood Models: An Intricate And Enchanting World Of Precision And Creativity

- 3d Wood Laser Cut Art 3D Wood Laser Cut Art: A Comprehensive Guide To Design, Creation, And Applications

- Shapeways Laser Cutting Shapeways Laser Cutting: A Comprehensive Guide To Advanced Manufacturing

- Laser Cut 3d Puzzle Free Download Laser Cut 3D Puzzle: Free Download And Assembly Guide

- 3d Laser Cut Cat 3D Laser Cut Cat: A Unique And Personalized Home Decor

Benefits of 3D Laser Cutting

Precision and Accuracy

Laser cutting utilizes a highly focused laser beam to precisely cut materials, resulting in clean edges, minimal burrs, and exact dimensions. This level of precision is unmatched by traditional cutting methods, making 3D laser cutting ideal for applications requiring intricate details and tight tolerances.

Speed and Efficiency

3D laser cutting operates at high speeds, significantly reducing production time compared to manual or mechanical cutting. Its automated nature eliminates the need for manual intervention, increasing efficiency and throughput.

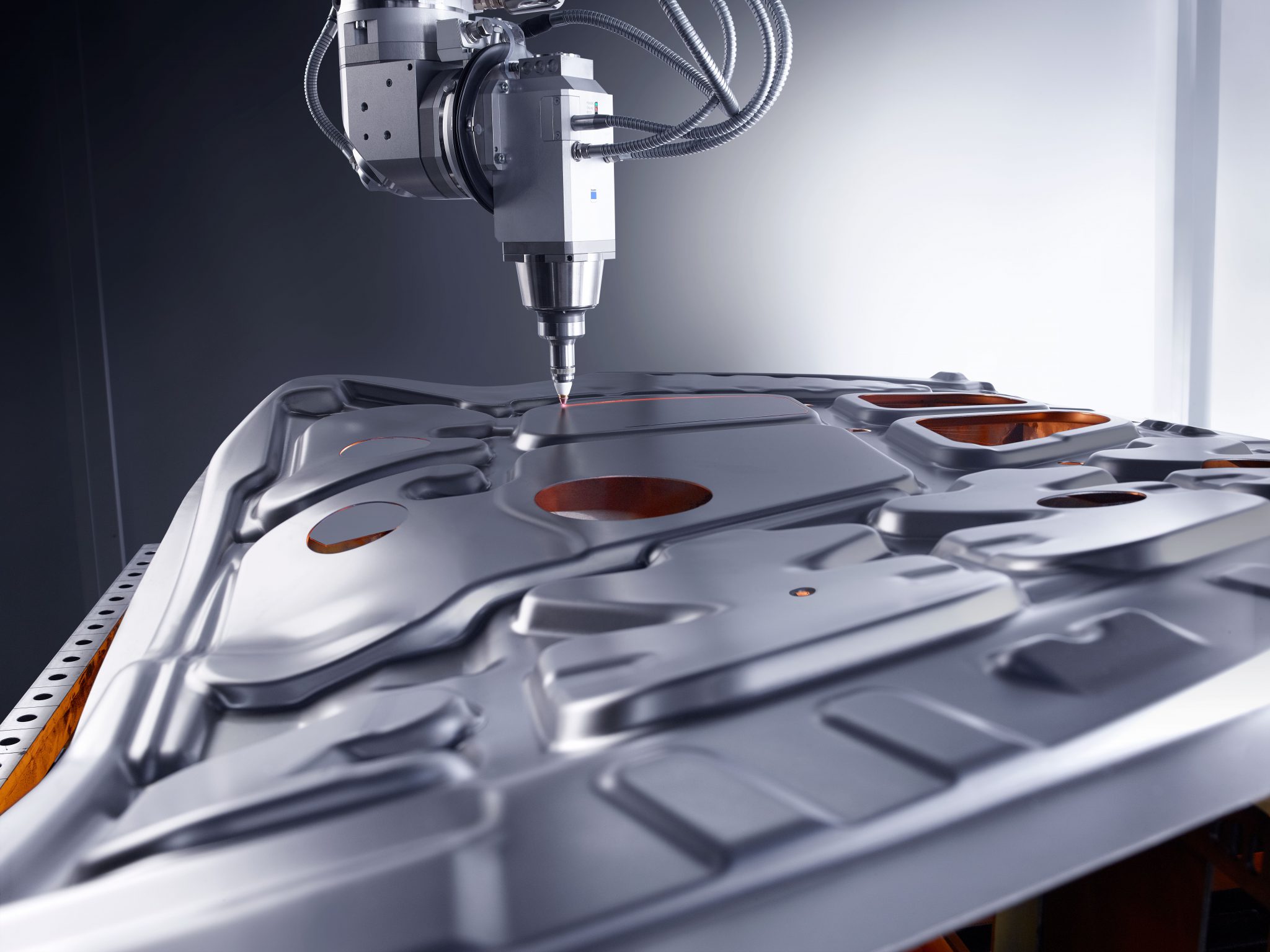

Automotive

The automotive industry relies on 3D laser cutting for the precise cutting of sheet metal, tubes, and profiles used in vehicle chassis, body panels, and interior components.

Medical

3D laser cutting finds application in the medical field for the fabrication of surgical instruments, prosthetics, and dental implants. Its precision enables the production of intricate and biocompatible devices.

Electronics

In the electronics industry, 3D laser cutting is used for the precise cutting of printed circuit boards (PCBs), circuit components, and enclosures.

Jewelry and Art

3D laser cutting has become a popular tool for jewelry makers and artists, allowing them to create intricate designs and personalized pieces with high precision.

Leading Providers of 3D Laser Cutting UK

XYZ Laser

XYZ Laser is a leading provider of 3D laser cutting machines in the UK. Their wide range of machines caters to various industries and offers advanced features such as high-speed cutting, precision optics, and user-friendly software.

Trotec Laser

Trotec Laser is another renowned supplier of 3D laser cutting systems. Their machines are known for their reliability, accuracy, and innovative features, including patented Dynamic Nesting technology for optimized material utilization.

Epilog Laser

Epilog Laser offers a comprehensive line of 3D laser cutters, ranging from entry-level to industrial-grade systems. Their machines are designed for ease of use, durability, and high-quality cutting results.

Conclusion

3D laser cutting UK is transforming the manufacturing landscape, offering businesses a host of benefits, including precision, speed, versatility, and cost-effectiveness. As the technology continues to advance, it is expected to play an increasingly vital role in various industries, enabling the production of innovative and high-quality products.

FAQs

What materials can be cut with 3D laser cutting?

3D laser cutting is capable of cutting a wide range of materials, including metals (steel, aluminum, stainless steel), plastics (acrylic, polycarbonate, ABS), wood, composites, and even certain fabrics.

What are the advantages of 3D laser cutting over traditional methods?

3D laser cutting offers several advantages over traditional methods, including:

- Precision and accuracy: Laser cutting provides precise cuts with minimal burrs and exact dimensions.

- Speed and efficiency: Laser cutting operates at high speeds, reducing production time and increasing throughput.

- Versatility: Laser cutting can process a wide range of materials, making it suitable for various applications.

- Cost-effectiveness: While the initial investment may be higher, laser cutting can save costs in the long run through reduced material waste, faster production times, and lower labor requirements.

How do I choose the right 3D laser cutting machine for my business?

When choosing a 3D laser cutting machine, consider the following factors:

- Material requirements: Determine the types of materials you need to cut and their thickness.

- Cutting speed and accuracy: Consider the desired cutting speed and the level of precision required for your applications.

- Machine size and capacity: Choose a machine that fits your workspace and meets your production volume requirements.

- Software and features: Evaluate the user-friendliness and capabilities of the software and additional features such as automatic nesting and fume extraction.

- Budget and ROI: Consider the upfront investment and the potential return on investment based on increased productivity and reduced costs.