3D Laser Cutting Wood: A Comprehensive Guide

Introduction

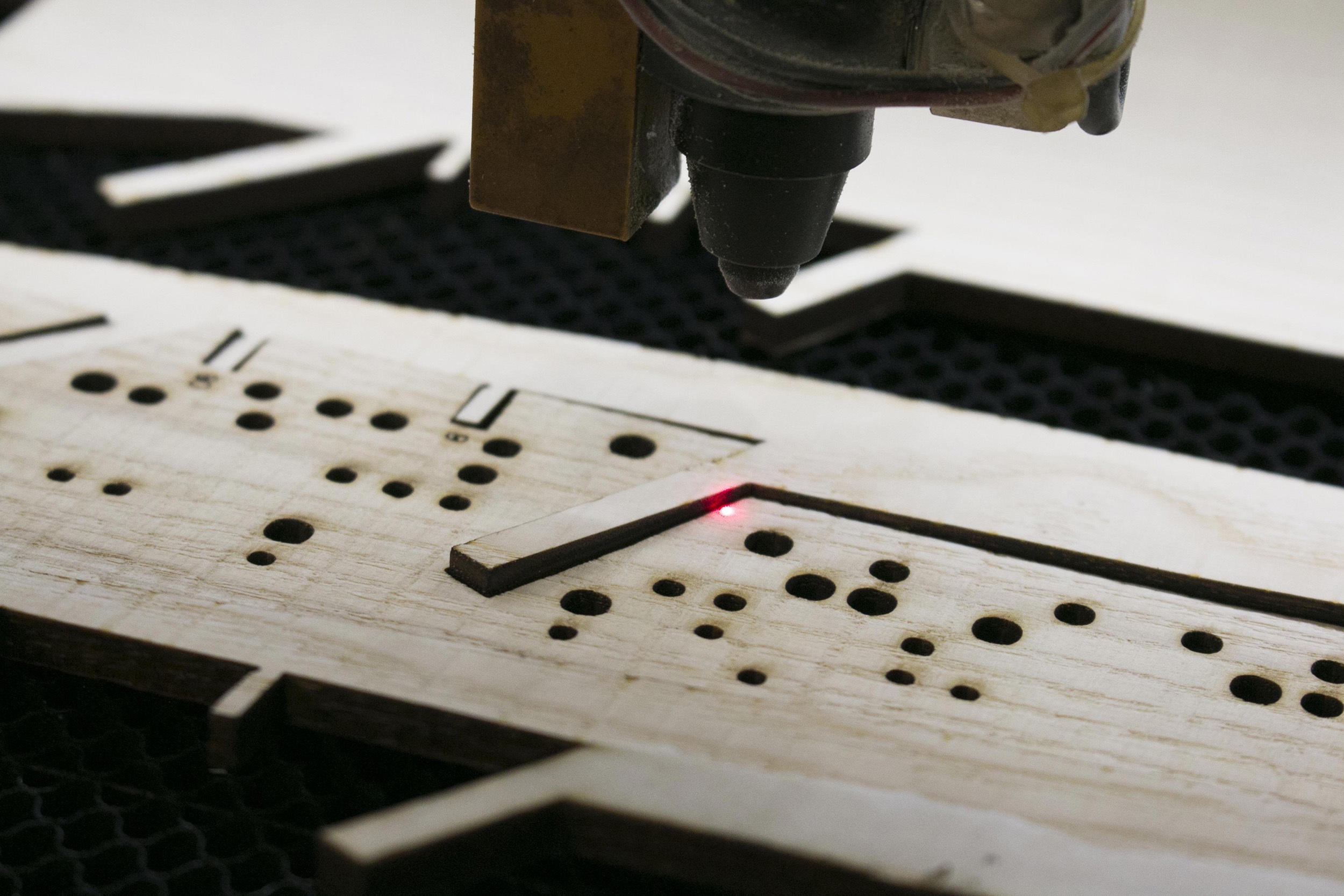

3D laser cutting wood has revolutionized the woodworking industry, enabling the creation of intricate and complex designs with precision and efficiency. This innovative technology utilizes a focused laser beam to vaporize material, resulting in clean cuts and smooth surfaces. In this comprehensive guide, we will delve into the intricacies of 3D laser cutting wood, exploring its advantages, applications, and best practices.

Table of Content

Advantages of 3D Laser Cutting Wood

Speed and Efficiency: Laser cutting is a high-speed process, significantly reducing production time compared to traditional cutting methods. This efficiency makes it an ideal solution for large-scale production.

Versatility: Laser cutters can cut a wide range of wood species and thicknesses, enabling the creation of diverse products and applications.

Reduced Material Waste: Laser cutting minimizes material waste by utilizing advanced nesting algorithms that optimize cutting patterns. This efficiency reduces material consumption and costs.

Non-Contact Cutting: Laser cutting is a non-contact process, eliminating the need for physical tools that can damage or deform the material.

Applications of 3D Laser Cutting Wood

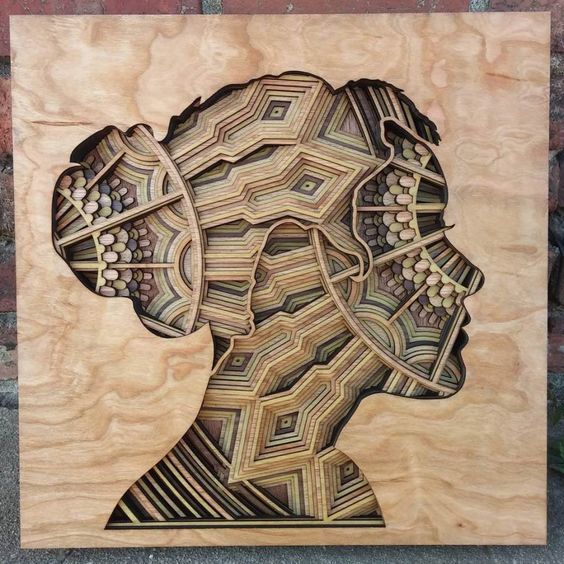

Furniture Design: Laser cutting enables the creation of custom furniture with unique and intricate designs, such as curved edges, intricate carvings, and decorative patterns.

Architectural Models: Laser cutters are used to create precise and detailed architectural models, providing architects and designers with a physical representation of their designs.

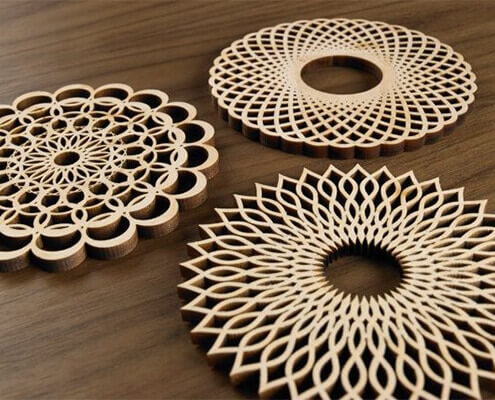

Art and Decor: Laser cutting wood allows artists to create unique and expressive works of art, including sculptures, wall hangings, and home décor items.

Industrial Prototyping: Laser cutting is used to create prototypes of industrial products, allowing designers to test and refine their designs before mass production.

Packaging and Display: Laser cutting wood is ideal for creating custom packaging solutions and display stands with precise cuts and intricate designs.

3D laser cutting wood has revolutionized the woodworking industry, enabling the creation of intricate and complex designs with precision and efficiency. This innovative technology utilizes a focused laser beam to vaporize material, resulting in clean cuts and smooth surfaces. In this comprehensive guide, we will delve into the intricacies of 3D laser cutting wood, exploring its advantages, applications, and best practices.

- 3d Laser Cut Uk 3D Laser Cutting UK: The Ultimate Guide To Precision Manufacturing

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- 3d Cutting Machine 3D Cutting Machine: A Comprehensive Guide

- 3d Laser Tube Cutting 3D Laser Tube Cutting: A Comprehensive Guide

- 3d 6 Axis Laser Cutting 3D 6-Axis Laser Cutting: Revolutionizing Complex Fabrication

Advantages of 3D Laser Cutting Wood

Precision and Accuracy: Laser cutting offers unparalleled precision, allowing for precise cuts and intricate designs. The laser beam’s narrow focus ensures clean, accurate cuts with minimal burrs or distortion.

Speed and Efficiency: Laser cutting is a high-speed process, significantly reducing production time compared to traditional cutting methods. This efficiency makes it an ideal solution for large-scale production.

Versatility: Laser cutters can cut a wide range of wood species and thicknesses, enabling the creation of diverse products and applications.

Reduced Material Waste: Laser cutting minimizes material waste by utilizing advanced nesting algorithms that optimize cutting patterns. This efficiency reduces material consumption and costs.

Best Practices for 3D Laser Cutting Wood

Material Selection: Choose high-quality wood species that are suitable for laser cutting, such as hardwoods like oak, maple, and walnut.

Design Optimization: Use design software to optimize cut paths and minimize material waste. Consider using nesting algorithms to maximize material utilization.

Laser Parameters: Determine the optimal laser power, speed, and focus settings based on the wood species and thickness being cut.

Ventilation: Ensure adequate ventilation to remove fumes and debris generated during laser cutting.

Safety Precautions: Wear appropriate safety gear, including eye protection and a respirator, and follow all safety guidelines.

Conclusion

3D laser cutting wood has emerged as a powerful tool for woodworking enthusiasts, professionals, and industrial manufacturers alike. Its advantages of precision, speed, versatility, and reduced material waste make it an ideal solution for a wide range of applications. By understanding the best practices and utilizing appropriate materials and techniques, users can harness the full potential of 3D laser cutting wood to create innovative and exceptional products.

FAQs

Q: What are the limitations of 3D laser cutting wood?

A: Laser cutting wood is not suitable for cutting very thick or dense materials. Additionally, the laser beam can cause some charring or discoloration on the cut edges.

Q: Can I use a laser cutter to engrave wood?

A: Yes, laser cutters can be used to engrave designs and patterns onto wood surfaces. The laser beam can create shallow cuts or etchings to achieve the desired effect.

Q: How do I maintain a laser cutter for optimal performance?

A: Regular cleaning and maintenance are crucial for maintaining laser cutter performance. Clean the optics, mirrors, and lenses regularly to remove debris. Calibrate the laser system periodically to ensure accurate cuts.