3D Metal Laser Cutting Machine Price: A Comprehensive Guide

Introduction

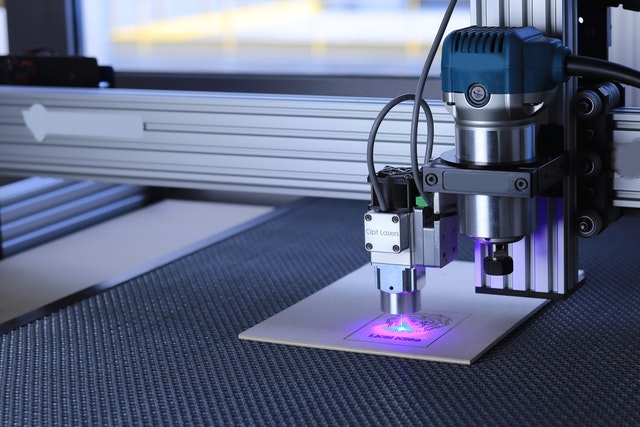

3D metal laser cutting machines have revolutionized the manufacturing industry, offering unparalleled precision, speed, and versatility. These machines utilize a focused laser beam to cut complex shapes and designs in a wide range of metal materials. However, understanding the pricing of 3D metal laser cutting machines can be complex. This article aims to provide a comprehensive guide to the factors that influence the price of these machines, helping buyers make informed decisions.

Table of Content

- 1 3D Metal Laser Cutting Machine Price: A Comprehensive Guide

- 1.1 Introduction

- 2 Factors Influencing 3D Metal Laser Cutting Machine Price

- 2.2 H2: Machine Features

- 2.3 H3: Brand and Reputation

- 3 Factors Influencing 3D Metal Laser Cutting Machine Price

- 3.4 H1: Machine Configuration

- 3.5 H3: Market Demand and Supply

- 4 Estimating 3D Metal Laser Cutting Machine Price

- 5 Conclusion

- 6 FAQs

Factors Influencing 3D Metal Laser Cutting Machine Price

1. Laser Power: Laser power is a critical factor that determines the cutting speed, accuracy, and material thickness capabilities of the machine. Higher laser power enables faster cutting and thicker material handling, but also increases the machine’s price.

2. Laser Type: Different laser types, such as fiber lasers, CO2 lasers, and green lasers, have varying capabilities and price points. Fiber lasers are generally more efficient and affordable, while CO2 lasers offer higher power outputs.

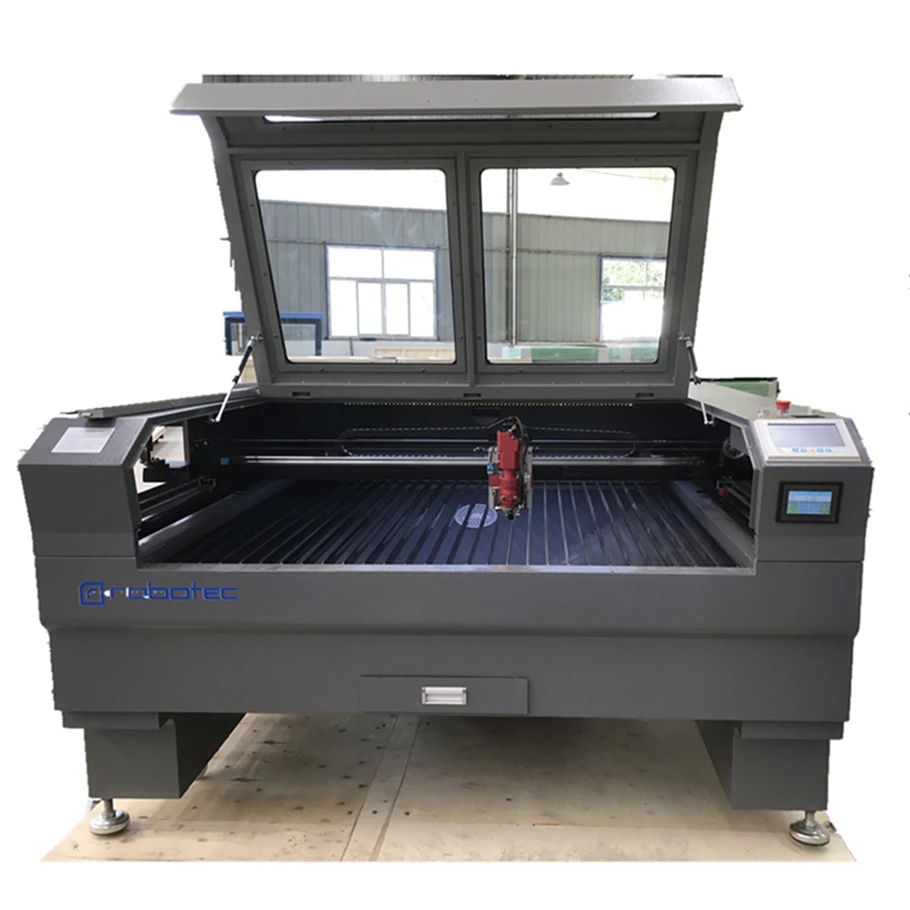

3. Cutting Bed Size: The size of the cutting bed determines the maximum workpiece dimensions that can be processed. Larger cutting beds typically cost more due to the increased material and manufacturing requirements.

4. Number of Axes: The number of axes in a 3D laser cutting machine determines its ability to move the laser head in different directions. Machines with more axes (e.g., 5-axis) offer greater flexibility and precision, but come at a higher cost.

H2: Machine Features

1. Automation: Automated features, such as automatic tool changers, material handling systems, and nesting software, improve productivity and reduce labor costs. However, these features increase the overall machine price.

2. Software: Advanced software for controlling the machine and optimizing cutting parameters can enhance efficiency and accuracy. High-end software solutions typically come with a premium price tag.

3. Accessories: Additional accessories, such as fume extraction systems, chiller units, and safety features, contribute to the overall cost of the machine.

H3: Brand and Reputation

The brand and reputation of the machine manufacturer play a significant role in pricing. Established brands with a proven track record of reliability and customer support tend to charge higher prices.

3D metal laser cutting machines have revolutionized the manufacturing industry, offering unparalleled precision, speed, and versatility. These machines utilize a focused laser beam to cut complex shapes and designs in a wide range of metal materials. However, understanding the pricing of 3D metal laser cutting machines can be complex. This article aims to provide a comprehensive guide to the factors that influence the price of these machines, helping buyers make informed decisions.

- 3d Printing And Laser Cutting Projects 3D Printing And Laser Cutting Projects: Unleashing Creativity And Innovation

- 3d Printer To Laser Cutting 3D Printer To Laser Cutting: Unveiling The Seamless Transition

- What Is 3d Laser Cutting What Is 3D Laser Cutting?

- 3d Laser Cut Crystal Cubes 3D Laser Cut Crystal Cubes: The Ultimate Guide To Captivating Decor And Personalized Gifts

- 3d Robot Fiber Laser Cutting Machine 3D Robot Fiber Laser Cutting Machine: A Comprehensive Guide

Factors Influencing 3D Metal Laser Cutting Machine Price

H1: Machine Configuration

1. Laser Power: Laser power is a critical factor that determines the cutting speed, accuracy, and material thickness capabilities of the machine. Higher laser power enables faster cutting and thicker material handling, but also increases the machine’s price.

2. Laser Type: Different laser types, such as fiber lasers, CO2 lasers, and green lasers, have varying capabilities and price points. Fiber lasers are generally more efficient and affordable, while CO2 lasers offer higher power outputs.

3. Cutting Bed Size: The size of the cutting bed determines the maximum workpiece dimensions that can be processed. Larger cutting beds typically cost more due to the increased material and manufacturing requirements.

H3: Market Demand and Supply

The market demand and supply for 3D metal laser cutting machines influence their pricing. Machines in high demand or with limited supply often command higher prices.

Estimating 3D Metal Laser Cutting Machine Price

To estimate the price of a 3D metal laser cutting machine, consider the following steps:

1. Determine Machine Configuration: Identify the required laser power, laser type, cutting bed size, and number of axes based on your application requirements.

2. Evaluate Machine Features: Decide on the level of automation, software, and accessories necessary for your operation.

3. Research Brands: Shortlist reputable machine manufacturers and compare their offerings and pricing.

4. Request Quotes: Contact multiple manufacturers to obtain detailed quotes that include machine specifications, features, and warranty terms.

5. Factor in Additional Costs: Consider the costs of installation, training, maintenance, and consumables when budgeting for the machine.

Conclusion

The price of 3D metal laser cutting machines can vary significantly depending on multiple factors. By understanding the key influences on pricing, buyers can make informed decisions and select the machine that best meets their specific requirements and budget. It is recommended to research thoroughly, compare offerings from different manufacturers, and request detailed quotes before making a purchase.

FAQs

Q: What is the average price range of 3D metal laser cutting machines?

A: The price range varies widely, typically from $100,000 to over $1 million, depending on the machine configuration and features.

Q: Which factors have the greatest impact on the price?

A: Laser power, cutting bed size, and number of axes are the most influential factors.

Q: Can I negotiate the price of a 3D metal laser cutting machine?

A: Yes, it is possible to negotiate with manufacturers based on factors such as volume discounts, trade-in options, and special promotions.

Q: What are the ongoing costs associated with owning a 3D metal laser cutting machine?

A: Ongoing costs include maintenance, consumables (e.g., lenses, nozzles), electricity, and labor for operation and programming.