3D Model Laser Cut: Precision and Versatility for Custom Creations

Introduction

In the realm of manufacturing and design, laser cutting has emerged as a game-changer, offering unmatched precision and flexibility in shaping various materials. When it comes to intricate three-dimensional (3D) models, laser cutting stands out as the ideal solution, allowing for the creation of complex geometries with exceptional accuracy. This article delves into the world of 3D model laser cutting, exploring its capabilities, benefits, and applications.

Table of Content

- 1 3D Model Laser Cut: Precision and Versatility for Custom Creations

- 1.1 Introduction

- 2 Capabilities of 3D Model Laser Cutting

- 2.2 Versatility

- 2.3 Customization

- 3 Benefits of 3D Model Laser Cutting

- 3.4 Reduced Production Time

- 3.5 Cost-Effectiveness

- 4 Capabilities of 3D Model Laser Cutting

- 4.6 Precision and Accuracy

- 4.7 Versatility

- 4.8 Enhanced Quality

- 5 Applications of 3D Model Laser Cutting

- 5.9 Architecture and Design

- 5.10 Automotive Industry

- 5.11 Medical Industry

- 5.12 Jewelry and Fashion

- 6 Conclusion

- 7 FAQs

Capabilities of 3D Model Laser Cutting

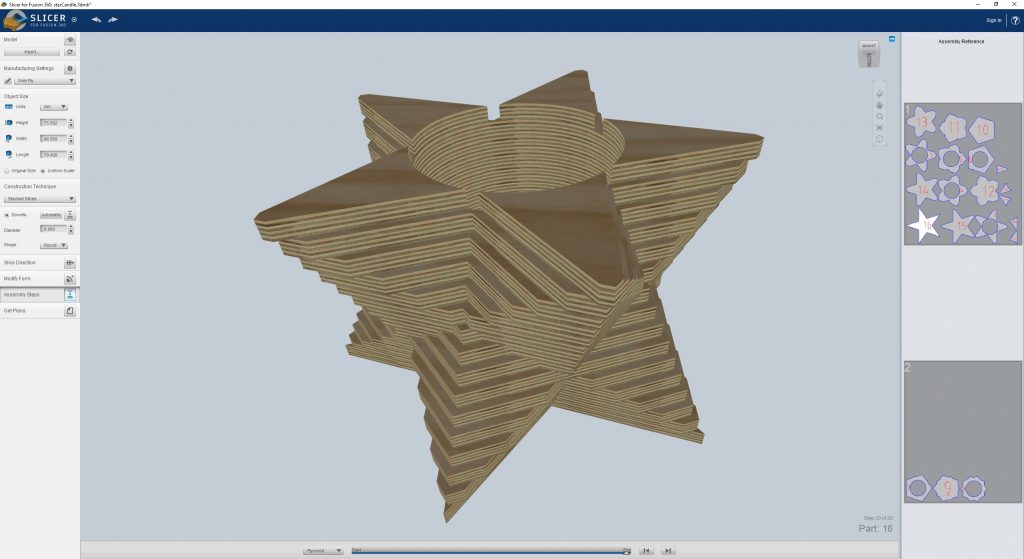

Laser cutting utilizes a focused laser beam to melt, vaporize, or burn materials, resulting in precise cuts with minimal distortion. This high level of accuracy is essential for creating complex 3D models, ensuring that intricate details and dimensions are meticulously replicated.

Versatility

Laser cutting can handle a wide range of materials, including metals, plastics, wood, and composites. This versatility enables the creation of 3D models from various materials, each with its unique properties and aesthetic appeal.

Customization

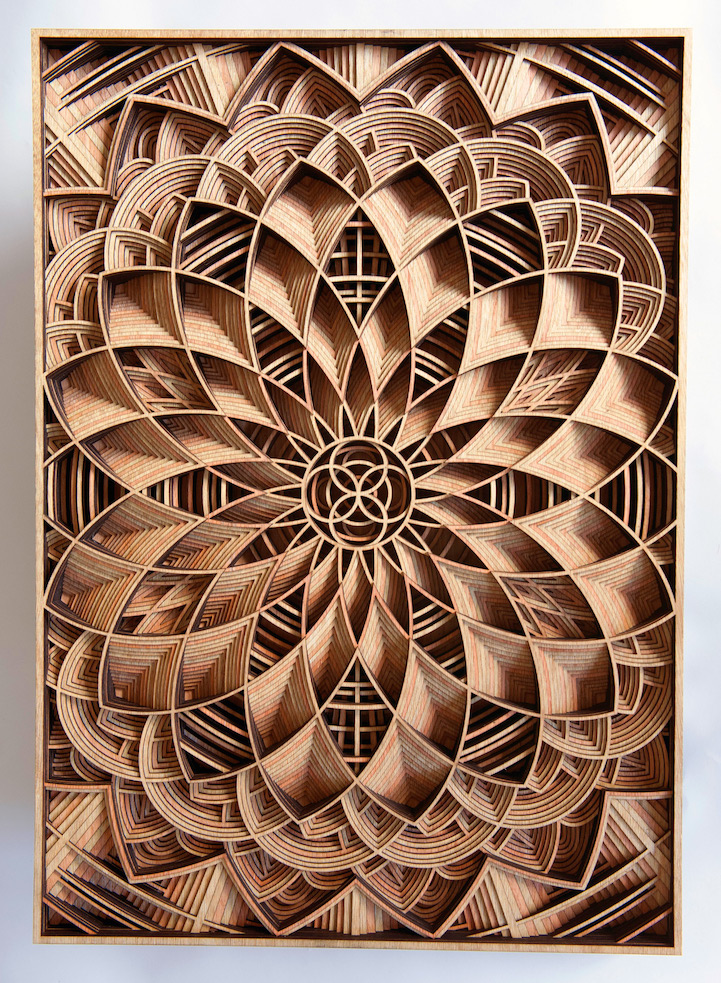

3D model laser cutting offers exceptional customization capabilities. Designers can create intricate models with unique shapes, patterns, and textures, allowing for the production of one-of-a-kind pieces.

Benefits of 3D Model Laser Cutting

Reduced Production Time

Laser cutting significantly reduces production time compared to traditional manufacturing methods. By automating the cutting process, laser cutters can operate 24/7, increasing efficiency and minimizing lead times.

Cost-Effectiveness

The precision and efficiency of laser cutting result in reduced material waste and labor costs. Additionally, the automated nature of the process eliminates the need for manual labor, further contributing to cost savings.

In the realm of manufacturing and design, laser cutting has emerged as a game-changer, offering unmatched precision and flexibility in shaping various materials. When it comes to intricate three-dimensional (3D) models, laser cutting stands out as the ideal solution, allowing for the creation of complex geometries with exceptional accuracy. This article delves into the world of 3D model laser cutting, exploring its capabilities, benefits, and applications.

- 3d Laser Cut Files Free 3D Laser Cut Files Free: Unleash Your Creativity

- 3d Laser Cut Christmas Tree Template 3D Laser Cut Christmas Tree Template: Elevate Your Festive Decorations

- 3d Laser Cutting Uk 3D Laser Cutting UK: A Comprehensive Guide To Advanced Manufacturing

- 3d Laser Crystal Engraving Machine 3D Laser Crystal Engraving Machine: Unlocking Limitless Creative Possibilities

- Difference Between Laser Cutting And 3d Printing Difference Between Laser Cutting And 3d Printing

Capabilities of 3D Model Laser Cutting

Precision and Accuracy

Laser cutting utilizes a focused laser beam to melt, vaporize, or burn materials, resulting in precise cuts with minimal distortion. This high level of accuracy is essential for creating complex 3D models, ensuring that intricate details and dimensions are meticulously replicated.

Versatility

Laser cutting can handle a wide range of materials, including metals, plastics, wood, and composites. This versatility enables the creation of 3D models from various materials, each with its unique properties and aesthetic appeal.

Enhanced Quality

Laser cutting produces clean and precise cuts, minimizing the need for post-processing and ensuring the highest quality of finished products.

Applications of 3D Model Laser Cutting

Architecture and Design

Laser-cut 3D models are widely used in architecture and design for creating intricate facades, sculptures, and decorative elements. They offer unparalleled precision and the ability to realize complex designs that would be challenging or impossible to produce using traditional methods.

Automotive Industry

The automotive industry utilizes 3D model laser cutting for prototyping and production of custom parts, such as dashboards, interior trim, and exterior panels. The accuracy and speed of laser cutting enable the rapid development and production of high-quality components.

Medical Industry

In the medical field, 3D model laser cutting is employed for the production of surgical tools, implants, and prosthetics. The precision of laser cutting ensures the creation of complex medical devices with precise dimensions and intricate details.

Jewelry and Fashion

Laser cutting has revolutionized the jewelry and fashion industries, enabling the creation of intricate jewelry pieces, accessories, and fabrics. The ability to cut delicate patterns and shapes allows designers to explore new frontiers of creativity.

Conclusion

3D model laser cutting is a transformative technology that has revolutionized the manufacturing and design industries. Its precision, versatility, and customization capabilities make it an ideal solution for creating complex and intricate 3D models from various materials. With its ability to reduce production time, enhance quality, and enable cost-effective customization, 3D model laser cutting continues to drive innovation and creativity across a wide range of applications.

FAQs

Q: What materials can be used for 3D model laser cutting?

A: Laser cutting can handle a variety of materials, including metals, plastics, wood, and composites.

Q: How accurate is 3D model laser cutting?

A: Laser cutting offers exceptional accuracy, with tolerances as tight as 0.001 inches.

Q: Is 3D model laser cutting suitable for prototyping?

A: Yes, 3D model laser cutting is ideal for prototyping, as it allows for rapid and precise production of complex designs.

Q: What are the benefits of 3D model laser cutting over traditional manufacturing methods?

A: 3D model laser cutting offers reduced production time, cost-effectiveness, and enhanced quality compared to traditional methods.

Q: What industries use 3D model laser cutting?

A: 3D model laser cutting finds applications in architecture and design, automotive, medical, jewelry and fashion, and many other industries.