3D Model Plane Laser Cut: A Comprehensive Guide

Introduction

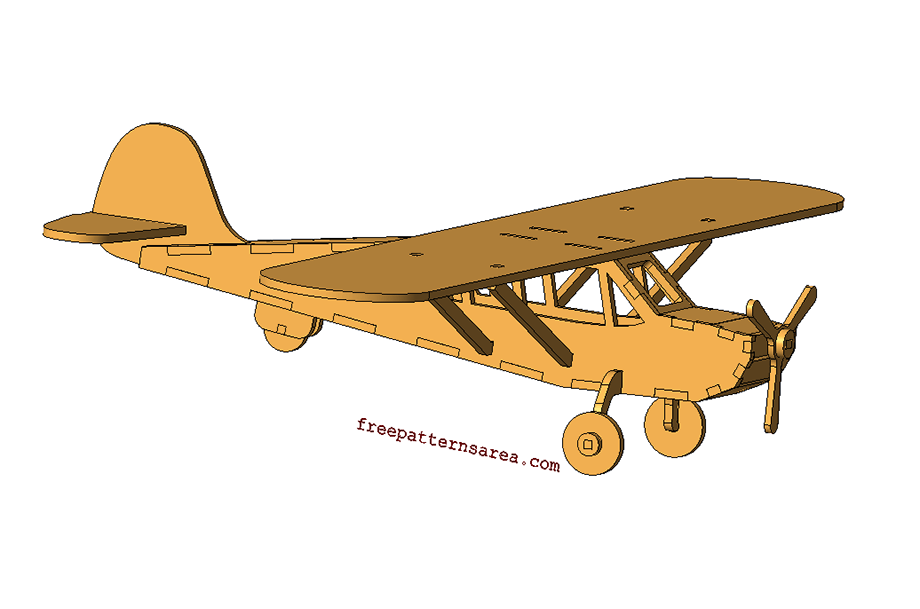

Laser cutting has revolutionized the manufacturing industry, allowing for precise and intricate designs to be created from various materials. 3D model planes are one such application where laser cutting excels, enabling the creation of realistic and detailed aircraft models. This article delves into the world of 3D model plane laser cutting, exploring its techniques, benefits, and applications.

Table of Content

- 1 3D Model Plane Laser Cut: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Laser Cutting Technology for 3D Model Planes

- 1.3 H2: Benefits of Laser Cutting for 3D Model Planes

- 1.4 H2: Applications of 3D Model Plane Laser Cutting

- 1.5 H3: Conclusion

- 1.6 H1: Laser Cutting Technology for 3D Model Planes

- 1.7 H2: Benefits of Laser Cutting for 3D Model Planes

- 1.8 FAQs

H1: Laser Cutting Technology for 3D Model Planes

H2: Benefits of Laser Cutting for 3D Model Planes

1. Precision and Detail: Laser cutting offers exceptional precision, allowing for intricate details and complex shapes to be cut with high accuracy. This results in realistic and detailed 3D model planes.

2. Speed and Efficiency: Laser cutters operate at high speeds, reducing production time compared to traditional manufacturing methods. This makes laser cutting an efficient solution for producing large quantities of 3D model planes.

3. Material Versatility: Laser cutters can cut a wide range of materials, including wood, acrylic, balsa wood, and even thin metals. This versatility allows for the creation of 3D model planes with varying weight, durability, and aesthetic qualities.

4. Design Flexibility: CAD software enables the creation of custom designs, allowing for the production of unique and personalized 3D model planes. This flexibility empowers modelers to create their own designs or modify existing ones.

H2: Applications of 3D Model Plane Laser Cutting

1. Hobby and Recreation: Laser-cut 3D model planes are popular among hobbyists and enthusiasts who enjoy building and flying scale or replica aircraft models.

2. Education and Research: 3D model planes can be used for educational purposes, demonstrating aerodynamic principles and showcasing the applications of laser cutting technology.

3. Commercial Production: Laser-cut 3D model planes can be produced commercially for sale to hobbyists, collectors, and educational institutions.

H3: Conclusion

Laser cutting has revolutionized the manufacturing industry, allowing for precise and intricate designs to be created from various materials. 3D model planes are one such application where laser cutting excels, enabling the creation of realistic and detailed aircraft models. This article delves into the world of 3D model plane laser cutting, exploring its techniques, benefits, and applications.

- 3d Laser Cut Template 3D Laser Cut Template: A Comprehensive Guide

- 3d Laser Cutting Melbourne 3D Laser Cutting Melbourne: The Ultimate Guide To Precision And Efficiency

- 3d Template Free 3D Template Free: Unleashing The Power Of 3D Design

- Laser Cut 3d Illusion Lamp Laser Cut 3D Illusion Lamp: A Captivating And Personalized Lighting Experience

- Laser Cut 3d Warehouse Laser Cut 3D Warehouse: Unleashing The Power Of Precision Fabrication

H1: Laser Cutting Technology for 3D Model Planes

Laser cutting involves using a high-powered laser beam to vaporize or melt material, creating precise cuts and shapes. In the context of 3D model planes, laser cutters utilize a computer-aided design (CAD) file to guide the laser beam, ensuring accuracy and repeatability.

H2: Benefits of Laser Cutting for 3D Model Planes

1. Precision and Detail: Laser cutting offers exceptional precision, allowing for intricate details and complex shapes to be cut with high accuracy. This results in realistic and detailed 3D model planes.

2. Speed and Efficiency: Laser cutters operate at high speeds, reducing production time compared to traditional manufacturing methods. This makes laser cutting an efficient solution for producing large quantities of 3D model planes.

Laser cutting technology has become an invaluable tool for creating 3D model planes. Its precision, speed, and material versatility offer numerous benefits, making it a preferred choice for hobbyists, educators, and commercial manufacturers alike. The ability to create intricate and detailed designs with high accuracy has revolutionized the production of 3D model planes, allowing for the creation of realistic and stunning models.

FAQs

1. What materials are suitable for laser cutting 3D model planes?

Common materials include wood, acrylic, balsa wood, and thin metals.

2. How do I create a CAD file for laser cutting a 3D model plane?

CAD software such as AutoCAD or SolidWorks can be used to design the model.

3. What safety precautions should I take when using a laser cutter?

Wear appropriate safety gear, ensure proper ventilation, and follow manufacturer instructions.

4. How can I improve the accuracy of laser-cut 3D model planes?

Use high-quality materials, ensure proper calibration of the laser cutter, and minimize vibrations during cutting.

5. Where can I find resources for 3D model plane designs?

Online repositories such as Thingiverse and MyMiniFactory provide free and paid designs.