3D Printer Into Laser Cutter: A Comprehensive Guide

Introduction

3D printers and laser cutters are two versatile machines that have revolutionized various industries. While 3D printers excel in creating three-dimensional objects, laser cutters offer precision cutting and engraving capabilities. This article explores the innovative concept of transforming a 3D printer into a laser cutter, providing insights into the process, benefits, and applications.

Table of Content

- 1 3D Printer Into Laser Cutter: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Converting a 3D Printer into a Laser Cutter

- 1.3 H3: Step-by-Step Conversion Process

- 1.4 H1: Converting a 3D Printer into a Laser Cutter

- 1.5 H2: Materials and Equipment Required

- 1.6 H2: Benefits of a 3D Printer Laser Cutter

- 1.7 H2: Applications of a 3D Printer Laser Cutter

- 1.8 H2: Safety Considerations

- 1.9 Conclusion

- 1.10 FAQs

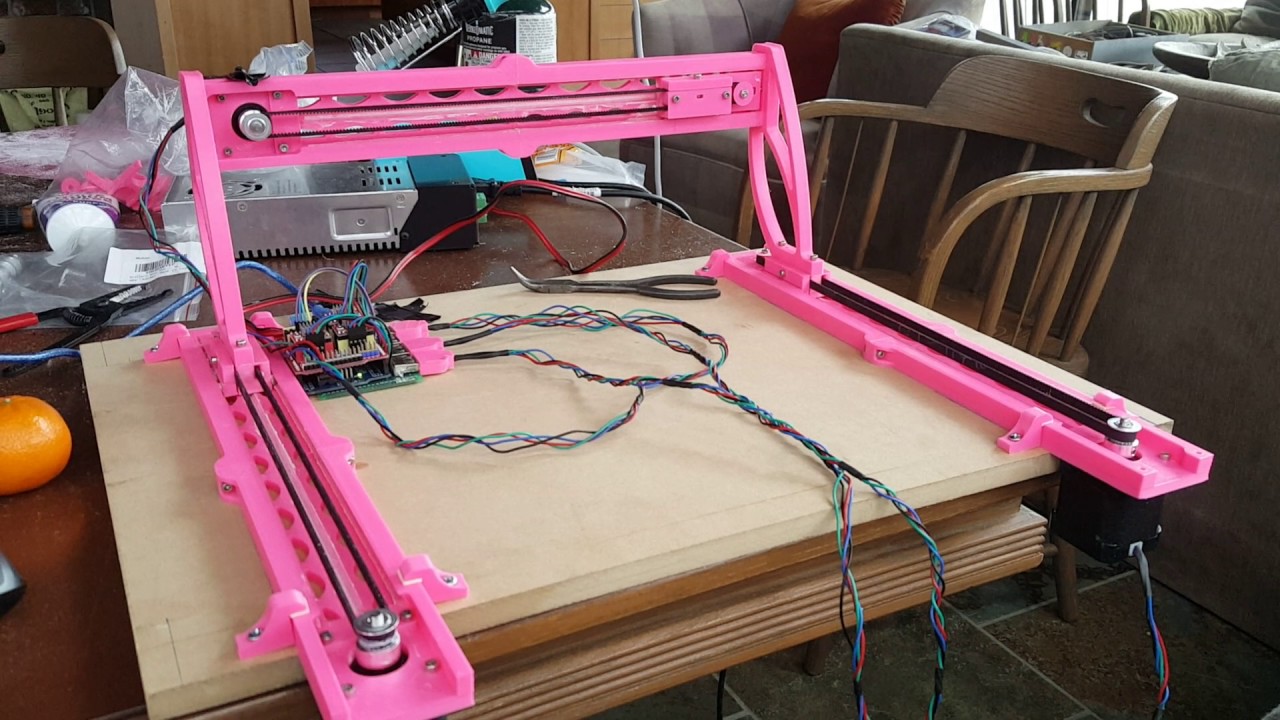

H1: Converting a 3D Printer into a Laser Cutter

- 3D printer with a sturdy frame

- Laser module (e.g., 405nm diode laser)

- Laser driver and control board

- Safety goggles

- Laser pointer for alignment

- Screwdriver and wrench

H3: Step-by-Step Conversion Process

- 3d Laser Cut Animal 3D Laser Cut Animal: A Comprehensive Guide To Laser Cutting Animal Designs

- 3d Robot Fiber Laser Cutting Machine 3D Robot Fiber Laser Cutting Machine: A Comprehensive Guide

- Laser Cut 3d Names Laser Cut 3D Names: A Personalized And Unique Gift

- Laser Cutting 3d Objects Laser Cutting 3D Objects: A Comprehensive Guide

- Laser Cut 3d Model Files Laser Cut 3D Model Files: A Comprehensive Guide

- 3D printer with a sturdy frame

- Laser module (e.g., 405nm diode laser)

- Remove the Extruder: Disassemble the 3D printer’s extruder and hot end assembly.

- Mount the Laser Module: Install the laser module onto the 3D printer’s carriage or print bed. Ensure proper alignment using the laser pointer.

- Connect the Laser Driver: Connect the laser driver to the laser module and control board according to the manufacturer’s instructions.

- Calibrate the Laser: Perform laser calibration to adjust the focus and power settings for optimal performance.

3D printers and laser cutters are two versatile machines that have revolutionized various industries. While 3D printers excel in creating three-dimensional objects, laser cutters offer precision cutting and engraving capabilities. This article explores the innovative concept of transforming a 3D printer into a laser cutter, providing insights into the process, benefits, and applications.

H1: Converting a 3D Printer into a Laser Cutter

H2: Materials and Equipment Required

H2: Benefits of a 3D Printer Laser Cutter

- Multifunctionality: Combines the capabilities of 3D printing and laser cutting in one device.

- Precision Cutting: Laser cutters offer high-precision cutting and engraving, ideal for intricate designs and materials like wood, acrylic, and leather.

- Cost-Effective: Transforming a 3D printer into a laser cutter can be a cost-effective alternative to purchasing a dedicated laser cutting machine.

- Customization: Allows for customization of the laser cutting setup based on specific project requirements.

H2: Applications of a 3D Printer Laser Cutter

- Prototyping and Design: Rapid prototyping of functional parts and models with precise laser-cut components.

- Art and Craft: Creating personalized engravings, decorative pieces, and custom jewelry using laser cutting techniques.

- Educational Projects: Engaging students in STEM education through hands-on projects involving laser cutting and 3D printing.

- Hobbyist Use: Making custom toys, models, and gadgets for personal enjoyment or small-scale production.

H2: Safety Considerations

- Wear Safety Goggles: Always wear laser safety goggles to protect eyes from laser radiation.

- Ventilate the Area: Laser cutting can release fumes, so ensure proper ventilation in the workspace.

- Avoid Direct Exposure: Keep hands and other body parts away from the laser beam path.

- Use Proper Materials: Choose materials suitable for laser cutting, such as wood, acrylic, or leather. Avoid cutting flammable or reflective materials.

Conclusion

Transforming a 3D printer into a laser cutter is an innovative and versatile solution that offers the combined benefits of both technologies. By following the outlined steps and adhering to safety guidelines, makers and hobbyists can unlock new possibilities in prototyping, design, and customization. This hybrid device empowers users with the flexibility to create precise cuts and engravings, making it an invaluable tool for various applications.

FAQs

Q: What types of materials can I cut with a 3D printer laser cutter?

A: Suitable materials include wood, acrylic, leather, paper, and thin plastics.

Q: How do I calibrate the laser?

A: Use a laser pointer to align the laser beam perpendicular to the cutting surface and adjust the focus and power settings for optimal results.

Q: Can I cut metal with a 3D printer laser cutter?

A: Most 3D printer laser cutters cannot cut metal due to its high reflectivity and melting point.

Q: What is the safety protocol for using a 3D printer laser cutter?

A: Always wear safety goggles, ventilate the area, avoid direct exposure to the laser beam, and use appropriate materials.

Q: Can I use any 3D printer to convert into a laser cutter?

A: The 3D printer should have a sturdy frame and a reliable control board to support the laser module and driver.