3D Printer vs. Laser Cutter: A Comprehensive Guide

Introduction

In the realm of modern manufacturing, 3D printers and laser cutters have emerged as two transformative technologies. Both offer unique capabilities for creating complex objects, but understanding their differences is crucial for making informed decisions about which technology best suits specific needs.

Table of Content

- 1 3D Printer vs. Laser Cutter: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: 3D Printer: The Ultimate Guide to Additive Manufacturing

- 1.2.1 H3: Types of 3D Printers

- 1.2.2 H3: Advantages of 3D Printers

- 1.3 H1: 3D Printer: The Ultimate Guide to Additive Manufacturing

- 1.3.3 H2: What is a 3D Printer?

- 1.3.4 H3: Types of 3D Printers

- 1.4 H2: Laser Cutter: The Power of Precision Cutting

- 1.4.5 H3: What is a Laser Cutter?

- 1.4.6 H3: Types of Laser Cutters

- 1.4.7 H3: Advantages of Laser Cutters

- 1.5 H2: Comparing 3D Printers and Laser Cutters

- 1.5.8 H3: Capabilities

- 1.5.9 H3: Materials

- 1.5.10 H3: Precision and Accuracy

- 1.5.11 H3: Speed and Efficiency

- 1.5.12 H3: Cost

- 1.6 H2: Choosing the Right Technology

- 1.7 H3: Hybrid Machines

- 1.8 Conclusion

- 1.9 FAQs

H1: 3D Printer: The Ultimate Guide to Additive Manufacturing

3D printers, also known as additive manufacturing machines, create three-dimensional objects by depositing material layer by layer. This process allows for the production of intricate designs that would be challenging or impossible to create using traditional methods.

H3: Types of 3D Printers

- Fused Deposition Modeling (FDM): Uses a thermoplastic filament that is melted and extruded through a nozzle.

- Stereolithography (SLA): Uses a liquid resin that is hardened by a laser beam.

- Selective Laser Sintering (SLS): Uses a powdered material that is fused together by a laser beam.

H3: Advantages of 3D Printers

- Rapid prototyping: Allows for quick and inexpensive creation of prototypes for design validation.

- Laser Cut 3d Snowflake H1: Laser Cut 3D Snowflake: A Festive And Intricate Holiday Decoration

- 3d Laser Cut Fish 3D Laser Cut Fish: A Comprehensive Guide

- 3d Laser Cutting Software 3D Laser Cutting Software: A Comprehensive Guide To Revolutionizing Your Fabrication

- 3d Robot Laser Cutting Machine 3D Robot Laser Cutting Machine: A Comprehensive Guide

- Sketchup Laser Cutting H1: Unleashing The Power Of SketchUp Laser Cutting: A Comprehensive Guide

- Complex geometries: Can create objects with intricate shapes that are difficult or impossible to produce with other methods.

- Customization: Enables the production of personalized objects and small-batch manufacturing.

- CO2 Laser Cutters: Utilize carbon dioxide gas to generate the laser beam.

- Fiber Laser Cutters: Use a fiber-optic cable to deliver the laser beam.

- Diode Laser Cutters: Employ semiconductor diodes to generate the laser beam.

- Precision cutting: Offers exceptional accuracy and precision for cutting intricate designs.

- Wide material compatibility: Can cut a variety of materials, including wood, metal, plastic, and leather.

- High speed and efficiency: Rapidly cuts through materials with minimal downtime.

- 3D Printers: Create three-dimensional objects by adding material.

- Laser Cutters: Cut or engrave materials by removing material.

- 3D Printers: Typically use plastics, resins, and metal powders.

- Laser Cutters: Can handle a wider range of materials, including wood, metal, plastic, and leather.

- 3D Printers: Can produce complex shapes, but accuracy may vary depending on the technology used.

- Laser Cutters: Offer high precision and accuracy for cutting and engraving.

- 3D Printers: Printing time can vary significantly depending on the size and complexity of the object.

- Laser Cutters: Rapid cutting speeds and high efficiency for large-scale production.

- 3D Printers: Initial investment can be higher, but operating costs are relatively low.

- Laser Cutters: Higher initial investment, but lower operating costs compared to 3D printers.

- 3D Printers: Ideal for prototyping, small-batch manufacturing, and creating complex geometries.

- Laser Cutters: Suitable for high-volume production, precision cutting, and engraving on a wide range of materials.

In the realm of modern manufacturing, 3D printers and laser cutters have emerged as two transformative technologies. Both offer unique capabilities for creating complex objects, but understanding their differences is crucial for making informed decisions about which technology best suits specific needs.

H1: 3D Printer: The Ultimate Guide to Additive Manufacturing

H2: What is a 3D Printer?

3D printers, also known as additive manufacturing machines, create three-dimensional objects by depositing material layer by layer. This process allows for the production of intricate designs that would be challenging or impossible to create using traditional methods.

H3: Types of 3D Printers

H2: Laser Cutter: The Power of Precision Cutting

H3: What is a Laser Cutter?

Laser cutters use a focused laser beam to cut or engrave materials. They are highly precise and can produce clean, burr-free cuts in a wide range of materials.

H3: Types of Laser Cutters

H3: Advantages of Laser Cutters

H2: Comparing 3D Printers and Laser Cutters

H3: Capabilities

H3: Materials

H3: Precision and Accuracy

H3: Speed and Efficiency

H3: Cost

H2: Choosing the Right Technology

The choice between a 3D printer and a laser cutter depends on the specific application.

H3: Hybrid Machines

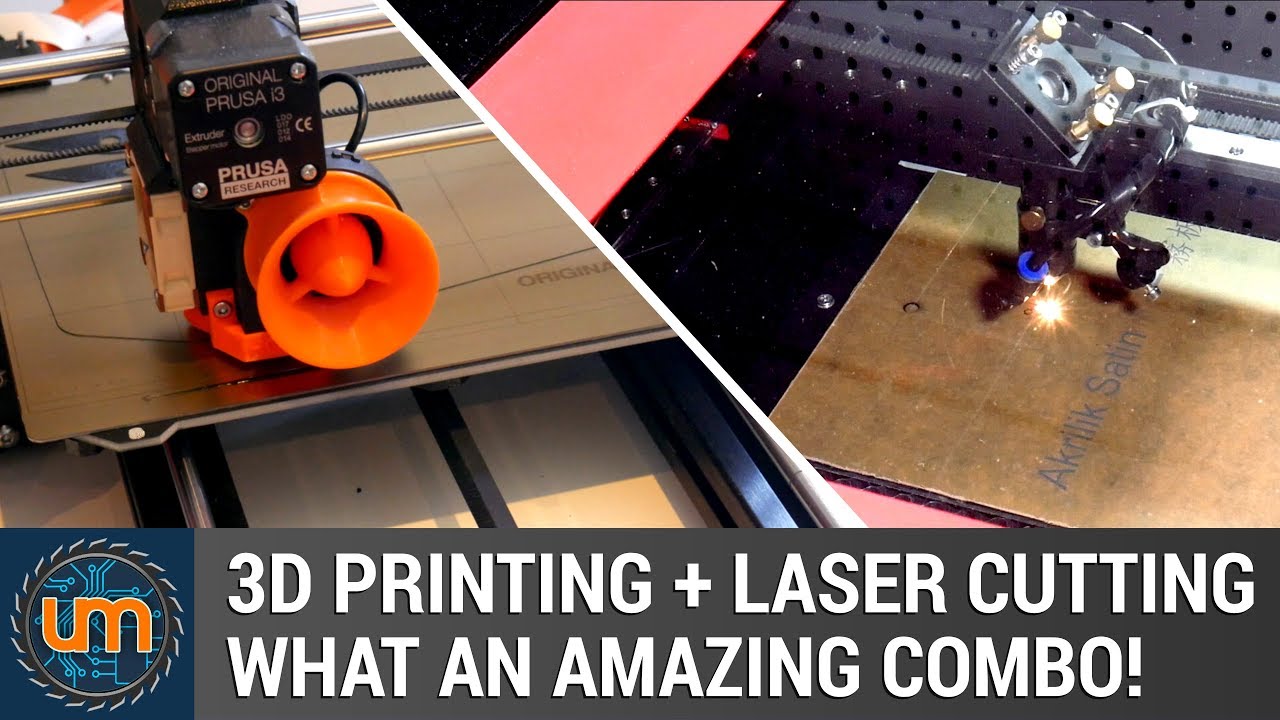

Some manufacturers offer hybrid machines that combine the capabilities of both 3D printers and laser cutters. These machines provide the versatility to create complex objects and perform precision cutting in a single system.

Conclusion

3D printers and laser cutters are both powerful tools that offer unique capabilities in the manufacturing industry. Understanding their differences and strengths is essential for making informed decisions about which technology best meets specific needs. By considering factors such as capabilities, materials, precision, speed, and cost, users can leverage these technologies to create innovative products and enhance their manufacturing processes.

FAQs

Q: Can 3D printers cut materials?

A: No, 3D printers add material to create objects. Laser cutters are used for cutting and engraving materials.

Q: Which technology is more versatile?

A: Laser cutters offer greater material compatibility and precision, making them more versatile for a wider range of applications.

Q: Which technology is more affordable?

A: 3D printers typically have lower operating costs, while laser cutters have higher initial investment costs.

Q: Can 3D printers create metal objects?

A: Yes, some 3D printers can use metal powders to create metal objects, but the process is more complex and expensive than using traditional metalworking methods.

Q: Which technology is better for prototyping?

A: 3D printers are ideal for rapid prototyping due to their ability to create complex shapes quickly and inexpensively.