3D Printing vs. Laser Cutting: A Comprehensive Comparison

In the realm of fabrication technologies, 3D printing and laser cutting stand out as two prominent methods with distinct capabilities and applications. Understanding the differences between these two technologies is crucial for businesses and individuals seeking to optimize their production processes. This article provides an in-depth comparison of 3D printing and laser cutting, exploring their advantages, limitations, and suitability for various applications.

H1: 3D Printing vs. Laser Cutting: An Overview

Table of Content

- 1 3D Printing vs. Laser Cutting: A Comprehensive Comparison

- 1.1 H1: 3D Printing vs. Laser Cutting: An Overview

- 1.2 H2: Advantages of 3D Printing

- 1.3 H2: Advantages of Laser Cutting

- 1.4 H1: 3D Printing vs. Laser Cutting: An Overview

- 1.5 H2: Advantages of 3D Printing

- 1.6 H3: Limitations of 3D Printing

- 1.7 H3: Limitations of Laser Cutting

- 1.8 H4: Suitability for Different Applications

- 1.9 H5: Conclusion

- 1.10 FAQs

3D Printing

Laser Cutting

Laser cutting, on the other hand, is a subtractive process that uses a focused laser beam to cut or engrave materials. The laser beam vaporizes or melts the material along a programmed path, creating precise cuts and intricate designs.

H2: Advantages of 3D Printing

1. Rapid Prototyping and Customization:

3D printing enables rapid prototyping, allowing designers and engineers to quickly create physical models for testing and design validation. The ability to customize designs easily makes 3D printing ideal for producing one-off parts or personalized products.

2. Complex Geometries and Internal Features:

3D printing excels at creating objects with complex geometries and internal features that would be difficult or impossible to produce using traditional manufacturing methods. This capability opens up new possibilities for innovation and product development.

3. Material Variety and Freedom:

3D printers can work with a wide range of materials, including plastics, metals, ceramics, and composites. This flexibility allows for the creation of objects with tailored properties and aesthetics.

H2: Advantages of Laser Cutting

H1: 3D Printing vs. Laser Cutting: An Overview

- Laser Cut 3d Dragon Laser Cut 3D Dragon: A Detailed Guide To Crafting A Majestic Masterpiece

- Laser Cut 3d Snowflake H1: Laser Cut 3D Snowflake: A Festive And Intricate Holiday Decoration

- 3d Laser Cut File 3D Laser Cut Files: A Comprehensive Guide For Designers And Makers

- 3d Laser Cut Bee 3D Laser Cut Bee: A Buzzing Masterpiece Of Precision And Creativity

- 3d Tube Cutting 3D Tube Cutting: A Comprehensive Guide To Advanced Manufacturing

3D Printing

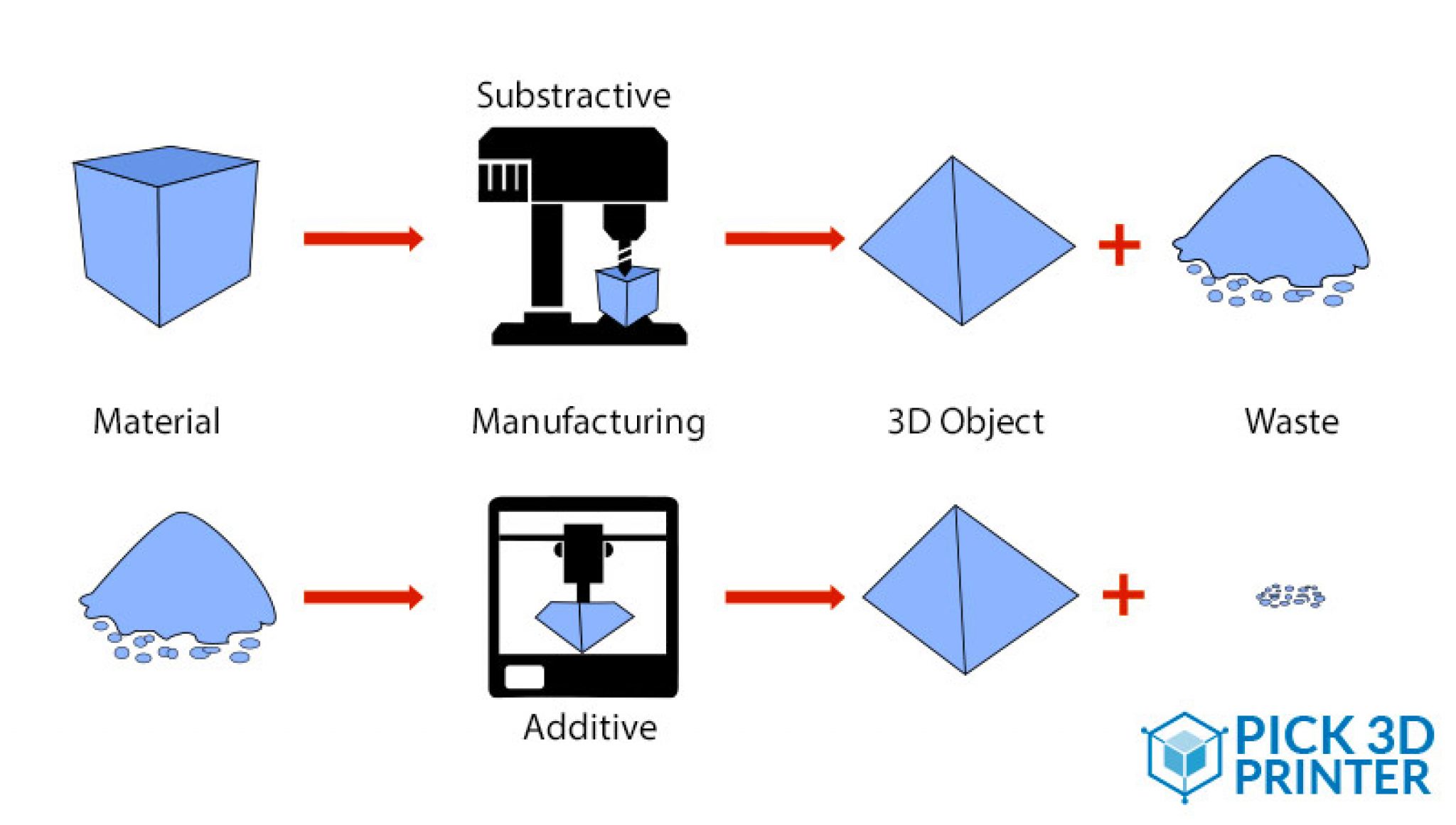

3D printing, also known as additive manufacturing, involves building objects layer by layer using a digital model. Materials such as plastic, metal, or ceramics are deposited or fused together to create complex shapes and geometries.

Laser Cutting

Laser cutting, on the other hand, is a subtractive process that uses a focused laser beam to cut or engrave materials. The laser beam vaporizes or melts the material along a programmed path, creating precise cuts and intricate designs.

H2: Advantages of 3D Printing

1. Precision and Accuracy:

Laser cutting offers exceptional precision and accuracy, making it suitable for applications where high-quality cuts and intricate designs are required. The laser beam provides a clean and burr-free cut edge.

2. Speed and Efficiency:

Laser cutting is a fast and efficient process, particularly for cutting thin materials. The laser beam’s high power density allows for rapid material removal, resulting in high production rates.

3. Material Compatibility:

Laser cutting can be used on a wide variety of materials, including metals, plastics, wood, and fabrics. This versatility makes it a valuable tool for various industries.

H3: Limitations of 3D Printing

1. Build Time and Layer Lines:

3D printing can be time-consuming, especially for larger objects. The layer-by-layer nature of the process can also result in visible layer lines on the surface of the printed object.

2. Strength and Material Properties:

The strength and material properties of 3D-printed objects can be limited compared to traditionally manufactured parts. Post-processing techniques may be required to enhance mechanical properties.

H3: Limitations of Laser Cutting

1. Material Thickness:

Laser cutting is primarily suitable for cutting thin materials. The maximum thickness that can be cut varies depending on the material and laser power.

2. Fume and Dust Generation:

Laser cutting can generate fumes and dust during operation. Proper ventilation and extraction systems are necessary to ensure a safe working environment.

H4: Suitability for Different Applications

3D Printing

- Rapid prototyping and design validation

- Production of custom or one-off parts

- Creation of complex geometries and internal features

- Applications in industries such as manufacturing, healthcare, and art

Laser Cutting

- Precision cutting of thin materials

- High-volume production of parts with intricate designs

- Engraving and marking on various surfaces

- Applications in industries such as metalworking, electronics, and packaging

H5: Conclusion

3D printing and laser cutting are both valuable technologies with distinct advantages and applications. 3D printing excels in rapid prototyping, customization, and complex geometries, while laser cutting offers precision, speed, and material compatibility. The choice between these technologies depends on the specific requirements of the project and the desired outcome. By understanding the capabilities and limitations of each technology, businesses and individuals can optimize their production processes and achieve the best results.

FAQs

Q: Which technology is better, 3D printing or laser cutting?

A: The choice between 3D printing and laser cutting depends on the specific requirements of the project. 3D printing is suitable for rapid prototyping, customization, and complex geometries, while laser cutting offers precision, speed, and material compatibility.

Q: What materials can be used with 3D printing and laser cutting?

A: 3D printing can work with a wide range of materials, including plastics, metals, ceramics, and composites. Laser cutting can be used on metals, plastics, wood, and fabrics.

Q: What are the costs associated with 3D printing and laser cutting?

A: The costs of 3D printing and laser cutting vary depending on factors such as the size and complexity of the project, the materials used, and the production volume. It is recommended to consult with a service provider for specific pricing information.