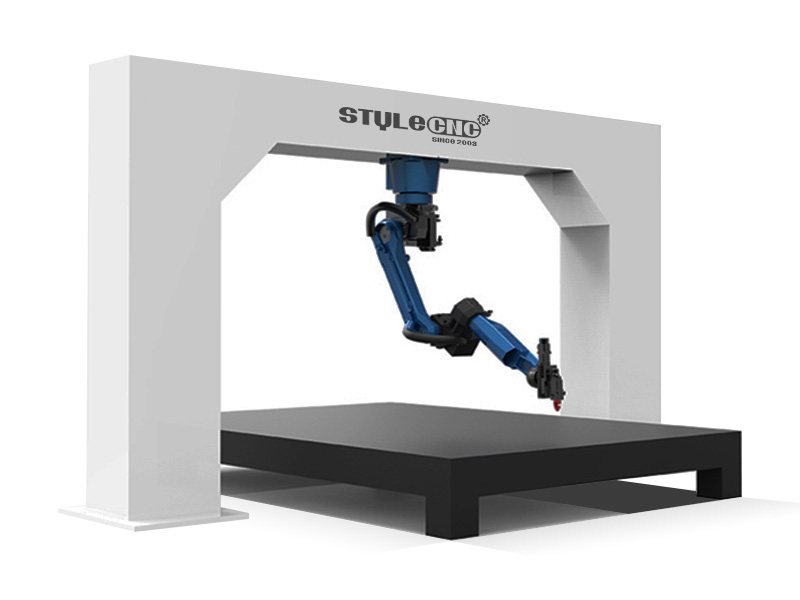

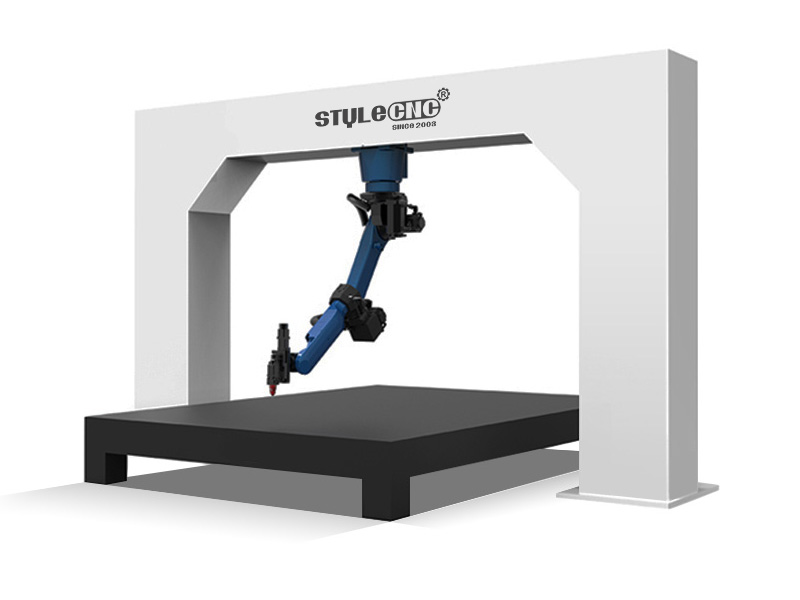

3D Robot Fiber Laser Cutting Machine: A Comprehensive Guide

Introduction

3D robot fiber laser cutting machines are advanced fabrication tools that utilize a high-powered laser beam to cut various materials with precision and efficiency. This article provides a comprehensive overview of these machines, including their key features, applications, benefits, and considerations.

Table of Content

Key Features

- Unlike traditional 2D laser cutters, 3D robot fiber laser cutters can cut complex three-dimensional shapes with high accuracy.

- They utilize a robotic arm that moves the laser head in multiple axes, allowing for intricate cuts on surfaces with varying angles and curves.

2. Fiber Laser Technology:

- These machines employ fiber lasers, which produce a highly concentrated beam with a small spot size.

- This results in precise cuts with minimal heat-affected zones and burrs.

3. High Power and Speed:

3D robot fiber laser cutting machines are advanced fabrication tools that utilize a high-powered laser beam to cut various materials with precision and efficiency. This article provides a comprehensive overview of these machines, including their key features, applications, benefits, and considerations.

- Laser Cutter Comparable To Glowforge Laser Cutter Comparable To Glowforge: A Comprehensive Guide

- 3d Laser Cutting Machine Company 3D Laser Cutting Machine: Revolutionizing Fabrication

- Laser Cut 3d Terrain Laser Cut 3D Terrain: Unleashing The Power Of Precision And Creativity

- 3d Laser Cutting Perth 3D Laser Cutting Perth: Precision And Innovation For Your Fabrication Needs

- 3d Laser Cut Box 3D Laser Cut Box: A Comprehensive Guide

Key Features

1. 3D Cutting Capabilities:

- Unlike traditional 2D laser cutters, 3D robot fiber laser cutters can cut complex three-dimensional shapes with high accuracy.

- They utilize a robotic arm that moves the laser head in multiple axes, allowing for intricate cuts on surfaces with varying angles and curves.

- 3D robot fiber laser cutters typically have high power outputs, ranging from 1 kW to 10 kW or more.

- This allows them to cut through thick materials quickly and efficiently.

- Sophisticated software and control systems guide the laser head with precision.

- These systems enable complex cutting paths, contouring, and nesting optimization.

4. Advanced Control Systems:

Applications

3D robot fiber laser cutting machines are used in a wide range of industries, including:

1. Automotive: Cutting of body panels, exhaust systems, and other automotive components.

2. Aerospace: Fabrication of aircraft parts, such as wings, fuselage panels, and engine components.

3. Medical: Production of surgical instruments, implants, and medical devices.

4. Electronics: Cutting of printed circuit boards (PCBs), heat sinks, and other electronic components.

5. Construction: Fabrication of metal structures, architectural panels, and HVAC components.

Benefits

1. Versatility: 3D robot fiber laser cutters can handle a wide range of materials, including steel, stainless steel, aluminum, titanium, and plastics.

2. Precision and Accuracy: These machines deliver precise cuts with minimal distortion and burrs, reducing the need for post-processing.

3. Speed and Efficiency: High power outputs and advanced control systems enable fast cutting speeds and high productivity.

4. Automation: Robotic operation allows for automated cutting processes, reducing labor costs and improving consistency.

5. Reduced Waste: Optimized nesting and contouring algorithms minimize material waste, saving costs and reducing environmental impact.

Considerations

1. Material Compatibility: Not all materials are suitable for laser cutting. Consider the specific material properties and compatibility before using a 3D robot fiber laser cutter.

2. Laser Power: The required laser power depends on the material thickness and cutting speed. Choose a machine with sufficient power for your intended applications.

3. Cutting Table Size: The cutting table size determines the maximum dimensions of the parts that can be processed. Select a table size that accommodates your workpiece requirements.

4. Software and Training: Advanced software and proper training are essential for effective operation of these machines. Invest in comprehensive training programs to maximize productivity and safety.

Conclusion

3D robot fiber laser cutting machines are powerful fabrication tools that offer versatility, precision, speed, and automation. They enable the production of complex three-dimensional parts across a wide range of industries. By understanding the key features, applications, benefits, and considerations of these machines, manufacturers can make informed decisions and leverage their capabilities to enhance productivity and innovation.

FAQs

1. What is the difference between 2D and 3D laser cutting?

2D laser cutters can only cut flat surfaces, while 3D laser cutters can cut complex three-dimensional shapes.

2. What materials can be cut with a 3D robot fiber laser cutter?

3D robot fiber laser cutters can cut a wide range of materials, including steel, stainless steel, aluminum, titanium, and plastics.

3. How accurate are 3D robot fiber laser cutters?

These machines can deliver precision cuts with tolerances of up to ±0.05 mm.

4. What is the cutting speed of a 3D robot fiber laser cutter?

Cutting speeds vary depending on the material and laser power. High-power machines can cut steel at speeds of up to 10 m/min or more.

5. Is it difficult to operate a 3D robot fiber laser cutter?

With proper training, these machines are relatively easy to operate. Advanced software and control systems simplify the process and enable automation.