3D to Laser Cut: A Comprehensive Guide to Converting 3D Models into Laser-Ready Designs

Introduction

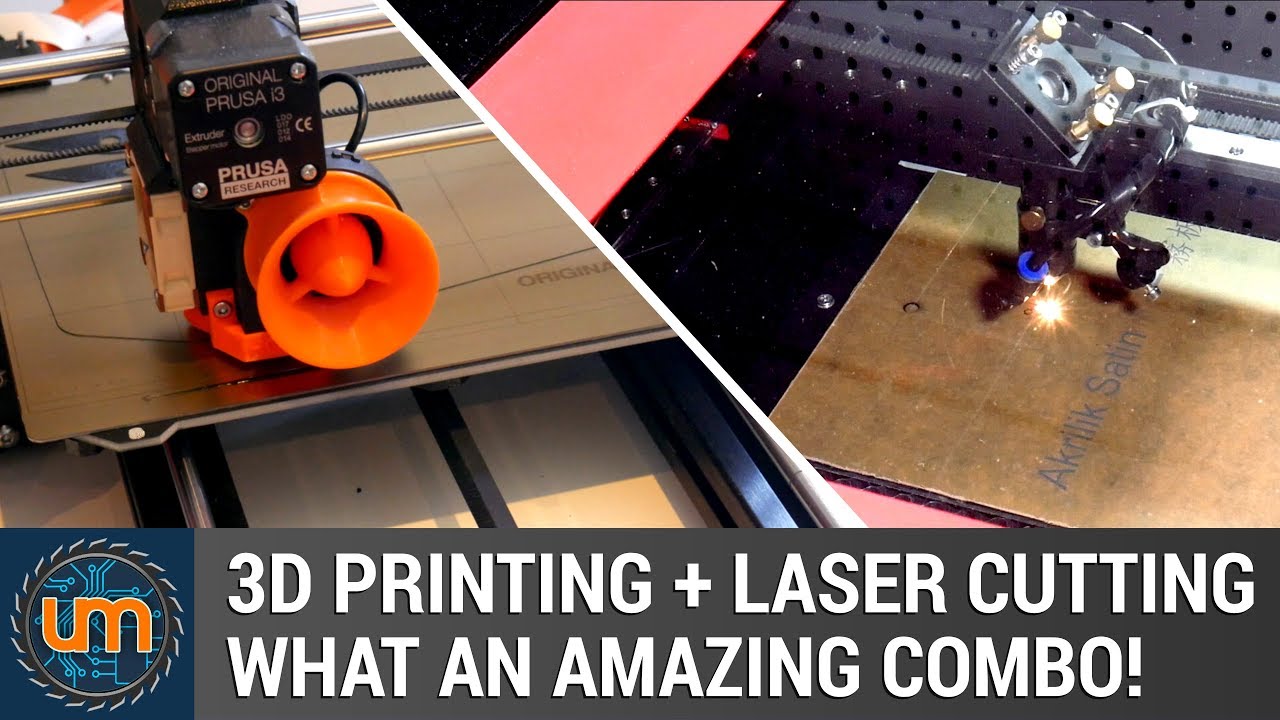

Laser cutting has revolutionized the fabrication industry, enabling precise and efficient cutting of complex shapes from a wide range of materials. With the advent of 3D modeling, it is now possible to seamlessly integrate 3D designs into the laser cutting process, unlocking endless possibilities for prototyping, manufacturing, and artistic expression. This article provides a comprehensive guide to 3D to laser cutting, empowering you with the knowledge and techniques to transform your 3D creations into laser-ready designs.

Table of Content

- 1 3D to Laser Cut: A Comprehensive Guide to Converting 3D Models into Laser-Ready Designs

- 1.1 Introduction

- 1.2 H1: Understanding the 3D to Laser Cutting Process

- 1.3 H2: Choosing the Right Software for 3D to Laser Cutting

- 1.4 H1: Understanding the 3D to Laser Cutting Process

- 1.5 H3: Optimizing 3D Models for Laser Cutting

- 1.6 H4: Laser Cutting Techniques for 3D Designs

- 1.7 H5: Applications of 3D to Laser Cutting

- 1.8 Conclusion

- 1.9 FAQs

H1: Understanding the 3D to Laser Cutting Process

- 3D Modeling: The first step is to create a 3D model of the object you wish to laser cut. This can be done using 3D modeling software such as AutoCAD, SolidWorks, or SketchUp.

- 2D Vectorization: Once the 3D model is complete, it must be converted into a 2D vector file. This process involves projecting the 3D model onto a flat plane, resulting in a set of lines and curves that define the outline of the object.

- Laser Cutting File Preparation: The 2D vector file is then imported into a laser cutting software program, which generates a laser cutting path. This path determines how the laser cutter will move to cut the object.

H2: Choosing the Right Software for 3D to Laser Cutting

Selecting the appropriate software is crucial for a successful 3D to laser cutting process. There are various software options available, each with its own strengths and weaknesses.

- 3D Modeling Software: As mentioned earlier, 3D modeling software is used to create the original 3D model. Popular options include AutoCAD, SolidWorks, and SketchUp.

- 2D Vectorization Software: Dedicated 2D vectorization software is used to convert 3D models into 2D vector files. Examples include Adobe Illustrator, Inkscape, and CorelDRAW.

- How To Laser Cut A 3d Model How To Laser Cut A 3D Model: A Comprehensive Guide

- 3d Laser Engraving Machine 3D Laser Engraving Machine: Unlocking Precision And Versatility In Manufacturing

- How To Design 3d Laser Cut Models How To Design 3D Laser Cut Models: A Comprehensive Guide

- 3d Laser Engraving 3D Laser Engraving: A Comprehensive Guide

- Laser Cut 3d Rose Laser Cut 3D Rose: A Guide To Intricate And Stunning Creations

- 3D Modeling: The first step is to create a 3D model of the object you wish to laser cut. This can be done using 3D modeling software such as AutoCAD, SolidWorks, or SketchUp.

- 2D Vectorization: Once the 3D model is complete, it must be converted into a 2D vector file. This process involves projecting the 3D model onto a flat plane, resulting in a set of lines and curves that define the outline of the object.

- Laser Cutting Software: Laser cutting software programs generate the laser cutting path from the 2D vector file. Common choices include LaserCut 5.3, LightBurn, and RDWorks.

- Model Complexity: Avoid overly complex models with intricate details, as they may be difficult to cut accurately.

- Wall Thickness: Ensure that the walls of your model are thick enough to withstand the laser cutting process without breaking or warping.

- Material Properties: Consider the material you will be laser cutting, as different materials have varying laser cutting properties.

- Laser Cutter Capabilities: Familiarize yourself with the capabilities of your laser cutter, including its maximum cutting thickness and minimum feature size.

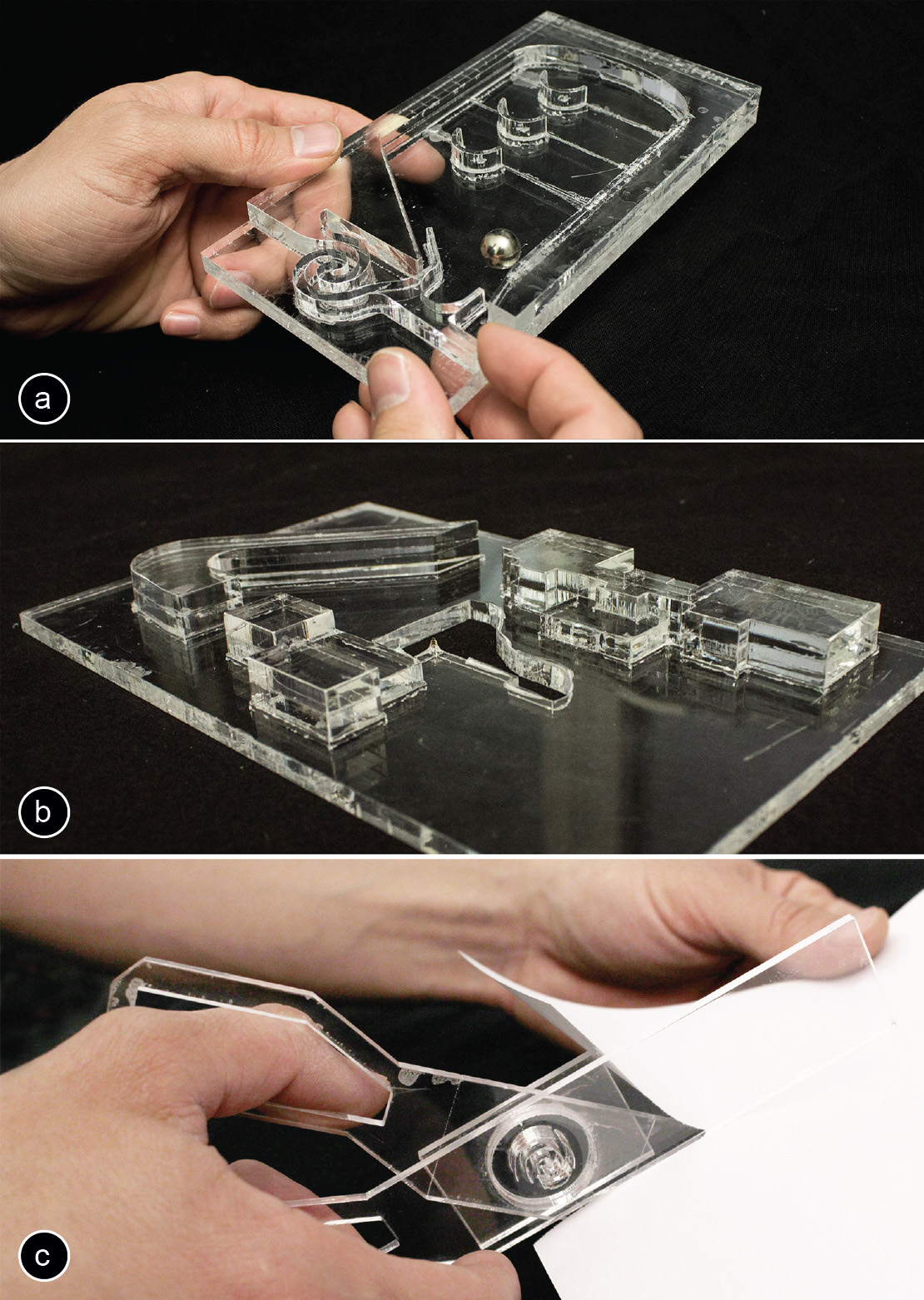

- Single-Pass Cutting: This technique involves cutting the entire 3D model in a single pass of the laser. It is suitable for simple designs with minimal depth.

- Multi-Pass Cutting: For more complex 3D models, multi-pass cutting is employed. The laser cuts the model in multiple passes, gradually removing material to achieve the desired depth.

- Engraving: Laser engraving can be used to add details or text to 3D objects. The laser beam rasterizes the surface of the object, creating a shallow engraving.

- 3D Engraving: Advanced laser cutting techniques, such as 3D engraving, allow for the creation of intricate 3D designs on the surface of objects.

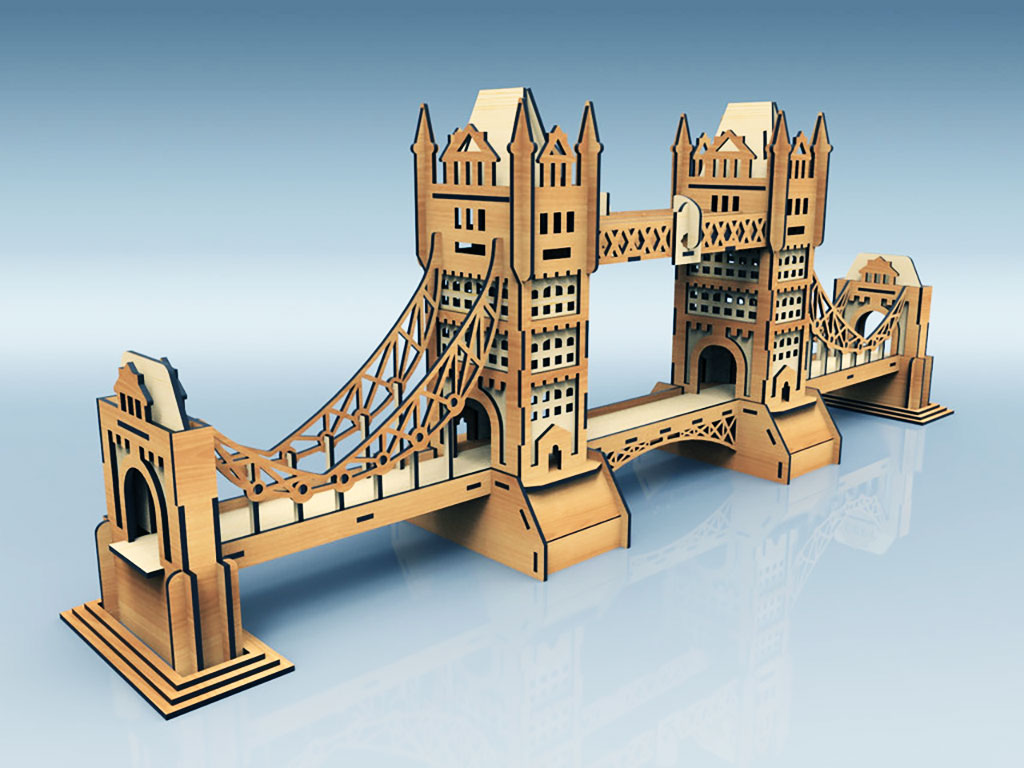

- Prototyping: Laser cutting is ideal for rapid prototyping, enabling quick and accurate production of functional prototypes from 3D models.

- Manufacturing: Laser cutting is used in manufacturing to produce complex and precise parts for a variety of products, including electronics, automotive components, and medical devices.

- Art and Design: Laser cutting has become a popular medium for artists and designers, allowing for the creation of unique and intricate sculptures, jewelry, and home décor.

Laser cutting has revolutionized the fabrication industry, enabling precise and efficient cutting of complex shapes from a wide range of materials. With the advent of 3D modeling, it is now possible to seamlessly integrate 3D designs into the laser cutting process, unlocking endless possibilities for prototyping, manufacturing, and artistic expression. This article provides a comprehensive guide to 3D to laser cutting, empowering you with the knowledge and techniques to transform your 3D creations into laser-ready designs.

H1: Understanding the 3D to Laser Cutting Process

The 3D to laser cutting process involves converting a 3D model into a 2D vector file that can be interpreted by a laser cutter. This conversion process encompasses several key steps:

H3: Optimizing 3D Models for Laser Cutting

To ensure successful laser cutting, it is essential to optimize your 3D models before vectorization. Here are some key considerations:

H4: Laser Cutting Techniques for 3D Designs

Laser cutting techniques for 3D designs can vary depending on the complexity of the model and the desired outcome. Here are some common approaches:

H5: Applications of 3D to Laser Cutting

3D to laser cutting has a wide range of applications across various industries:

Conclusion

3D to laser cutting is a powerful technique that enables the transformation of digital 3D models into tangible laser-cut creations. By understanding the process, selecting the appropriate software, optimizing 3D models, and utilizing various laser cutting techniques, you can unlock the full potential of this technology. From prototyping to manufacturing and artistic expression, 3D to laser cutting empowers you to bring your ideas to life with precision and creativity.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting involves cutting flat materials, while 3D laser cutting involves cutting 3D objects or creating 3D designs on surfaces.

Q: Can any 3D model be laser cut?

A: Not all 3D models are suitable for laser cutting. Complex models with intricate details or thin walls may not be feasible to cut accurately.

Q: What materials can be laser cut using 3D designs?

A: Laser cutting can be performed on a wide range of materials, including wood, acrylic, metal, and leather. However, material properties and laser cutter capabilities should be considered.

Q: How can I improve the quality of my laser-cut 3D designs?

A: Optimizing 3D models, selecting the appropriate laser cutting technique, and using high-quality materials can significantly improve the quality of laser-cut 3D designs.

Q: What are the advantages of 3D to laser cutting?

A: 3D to laser cutting offers advantages such as precision, versatility, and the ability to create complex designs that would be difficult or impossible to produce using traditional manufacturing methods.