3D Tube Laser Cutting Machine: A Comprehensive Guide

Introduction

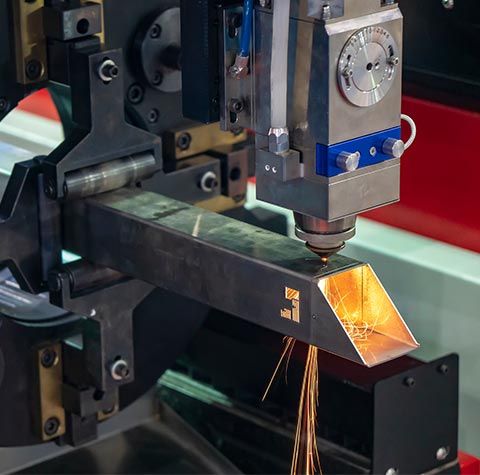

A 3D tube laser cutting machine is a cutting-edge fabrication tool that utilizes a laser beam to precisely cut and shape metal tubes. This advanced technology offers numerous advantages over traditional cutting methods, making it an essential tool in various industries, including automotive, aerospace, construction, and medical equipment manufacturing.

Table of Content

- 1 3D Tube Laser Cutting Machine: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Components and Functionality of a 3D Tube Laser Cutting Machine

- 1.2.1 H2: Motion Control System

- 1.2.2 H2: Cutting Head

- 1.2.3 H2: Tube Feeding System

- 1.3 H1: Benefits of 3D Tube Laser Cutting

- 1.3.4 H2: High Precision and Accuracy

- 1.4 H1: Components and Functionality of a 3D Tube Laser Cutting Machine

- 1.4.5 H2: Laser Source

- 1.4.6 H2: Motion Control System

- 1.4.7 H2: Fast and Efficient

- 1.4.8 H2: Versatility

- 1.4.9 H2: Cost-Effective

- 1.5 H1: Applications of 3D Tube Laser Cutting

- 1.5.10 H2: Automotive Industry

- 1.5.11 H2: Aerospace Industry

- 1.5.12 H2: Construction Industry

- 1.5.13 H2: Medical Equipment Manufacturing

- 1.6 H1: Conclusion

- 1.7 FAQs

H1: Components and Functionality of a 3D Tube Laser Cutting Machine

The laser source is the core component of a 3D tube laser cutting machine. It generates a high-power laser beam that is focused and directed onto the metal tube. Common laser sources used in these machines include fiber lasers, CO2 lasers, and excimer lasers.

H2: Motion Control System

The motion control system ensures precise movement of the laser head and the tube. It consists of a computer numerical control (CNC) unit, servo motors, and encoders. The CNC unit interprets the cutting instructions and controls the movement of the machine components.

H2: Cutting Head

The cutting head houses the laser beam optics and focuses the beam onto the cutting surface. It can rotate and tilt to cut tubes at different angles. The cutting head also contains a gas assist system to remove molten material from the cut zone.

H2: Tube Feeding System

The tube feeding system automatically loads and aligns the tubes to be cut. It typically consists of a conveyor belt, a loading table, and a clamping mechanism to secure the tubes.

H1: Benefits of 3D Tube Laser Cutting

H2: High Precision and Accuracy

3D tube laser cutting machines offer exceptional precision and accuracy, allowing for intricate cuts and complex shapes. The laser beam is precisely controlled, resulting in clean, burr-free cuts with minimal distortion.

A 3D tube laser cutting machine is a cutting-edge fabrication tool that utilizes a laser beam to precisely cut and shape metal tubes. This advanced technology offers numerous advantages over traditional cutting methods, making it an essential tool in various industries, including automotive, aerospace, construction, and medical equipment manufacturing.

- 3d Mandala Laser Cut 3D Mandala Laser Cut: An Immersive Art Form

- 3d Laser Cut Art 3D Laser Cut Art: Unlocking A World Of Dimensional Creativity

- Laser Cut Catan Thingiverse Laser Cut Catan Thingiverse: Elevate Your Board Game Experience

- 3d Laser Cutting Brisbane 3D Laser Cutting Brisbane: A Comprehensive Guide

- 3d Hubs Laser Cutting 3D Hubs Laser Cutting: A Comprehensive Guide To Precision Manufacturing

H1: Components and Functionality of a 3D Tube Laser Cutting Machine

H2: Laser Source

The laser source is the core component of a 3D tube laser cutting machine. It generates a high-power laser beam that is focused and directed onto the metal tube. Common laser sources used in these machines include fiber lasers, CO2 lasers, and excimer lasers.

H2: Motion Control System

The motion control system ensures precise movement of the laser head and the tube. It consists of a computer numerical control (CNC) unit, servo motors, and encoders. The CNC unit interprets the cutting instructions and controls the movement of the machine components.

H2: Fast and Efficient

These machines operate at high speeds, significantly reducing production time. The automated feeding system ensures continuous cutting, minimizing downtime and maximizing productivity.

H2: Versatility

3D tube laser cutting machines can cut a wide range of metal tubes, including stainless steel, aluminum, copper, and titanium. They can handle tubes of various diameters and thicknesses, making them suitable for a variety of applications.

H2: Cost-Effective

Although the initial investment in a 3D tube laser cutting machine can be significant, its long-term benefits can outweigh the costs. The high efficiency, reduced waste, and increased production capacity can lead to significant savings.

H1: Applications of 3D Tube Laser Cutting

H2: Automotive Industry

3D tube laser cutting is widely used in the automotive industry for cutting exhaust systems, chassis components, and other tubular parts. It provides precise cuts and complex bends, reducing assembly time and improving vehicle performance.

H2: Aerospace Industry

In the aerospace industry, 3D tube laser cutting is essential for fabricating lightweight and durable components for aircraft and spacecraft. It enables the production of intricate shapes and complex structures with high precision.

H2: Construction Industry

3D tube laser cutting is utilized in the construction industry for cutting structural beams, railings, and other tubular components. It offers precise cuts and efficient fabrication, ensuring the accuracy and integrity of building structures.

H2: Medical Equipment Manufacturing

3D tube laser cutting is employed in the medical equipment manufacturing industry for cutting surgical instruments, implants, and other medical devices. It provides precise cuts and smooth surfaces, ensuring the functionality and safety of medical devices.

H1: Conclusion

3D tube laser cutting machines are indispensable tools in various industries due to their high precision, efficiency, versatility, and cost-effectiveness. They enable the fabrication of complex and intricate tubular components with exceptional quality. As technology continues to advance, 3D tube laser cutting machines will continue to play a vital role in driving innovation and productivity across multiple sectors.

FAQs

Q: What is the maximum cutting thickness for a 3D tube laser cutting machine?

A: The maximum cutting thickness varies depending on the machine’s laser source and power. Typically, fiber laser cutting machines can cut tubes up to 20 mm thick, while CO2 lasers can cut thicker tubes.

Q: Can 3D tube laser cutting machines cut non-metallic materials?

A: No, 3D tube laser cutting machines are primarily designed for cutting metal tubes. They cannot cut non-metallic materials such as wood, plastic, or rubber.

Q: How do I choose the right 3D tube laser cutting machine for my business?

A: Consider factors such as the tube diameter and thickness you need to cut, the required cutting speed and accuracy, and the budget you have. Consult with a reputable manufacturer to determine the best machine for your specific needs.