H1: Cut MDF Wooden Laser Cut: A Comprehensive Guide

H2: Introduction

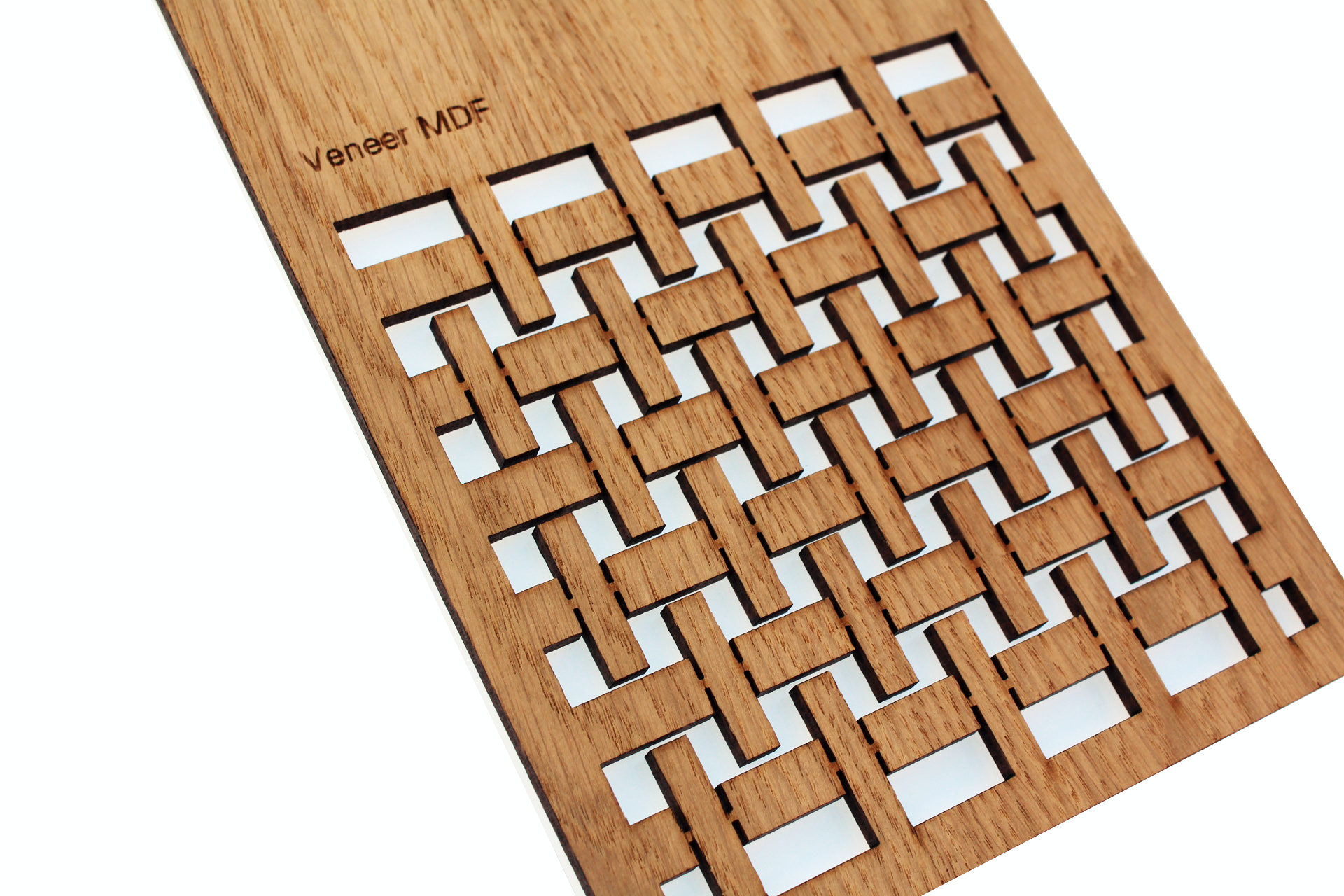

Medium-density fiberboard (MDF) is a versatile material widely used in various industries, including furniture making, cabinetry, and interior design. Laser cutting has emerged as a precise and efficient method for shaping MDF into intricate designs and components. This article provides a comprehensive guide to cut MDF wooden laser cut, covering techniques, benefits, and applications.

Table of Content

- 1 H1: Cut MDF Wooden Laser Cut: A Comprehensive Guide

- 1.1 H2: Introduction

- 1.2 H2: Laser Cutting Techniques

- 1.3 H3: Benefits of Laser Cutting MDF

- 1.4 H2: Laser Cutting Techniques

- 1.5 H2: Applications of Cut MDF Wooden Laser Cut

- 1.6 H2: Considerations for Laser Cutting MDF

- 1.7 H2: Conclusion

- 1.8 H2: FAQs

H2: Laser Cutting Techniques

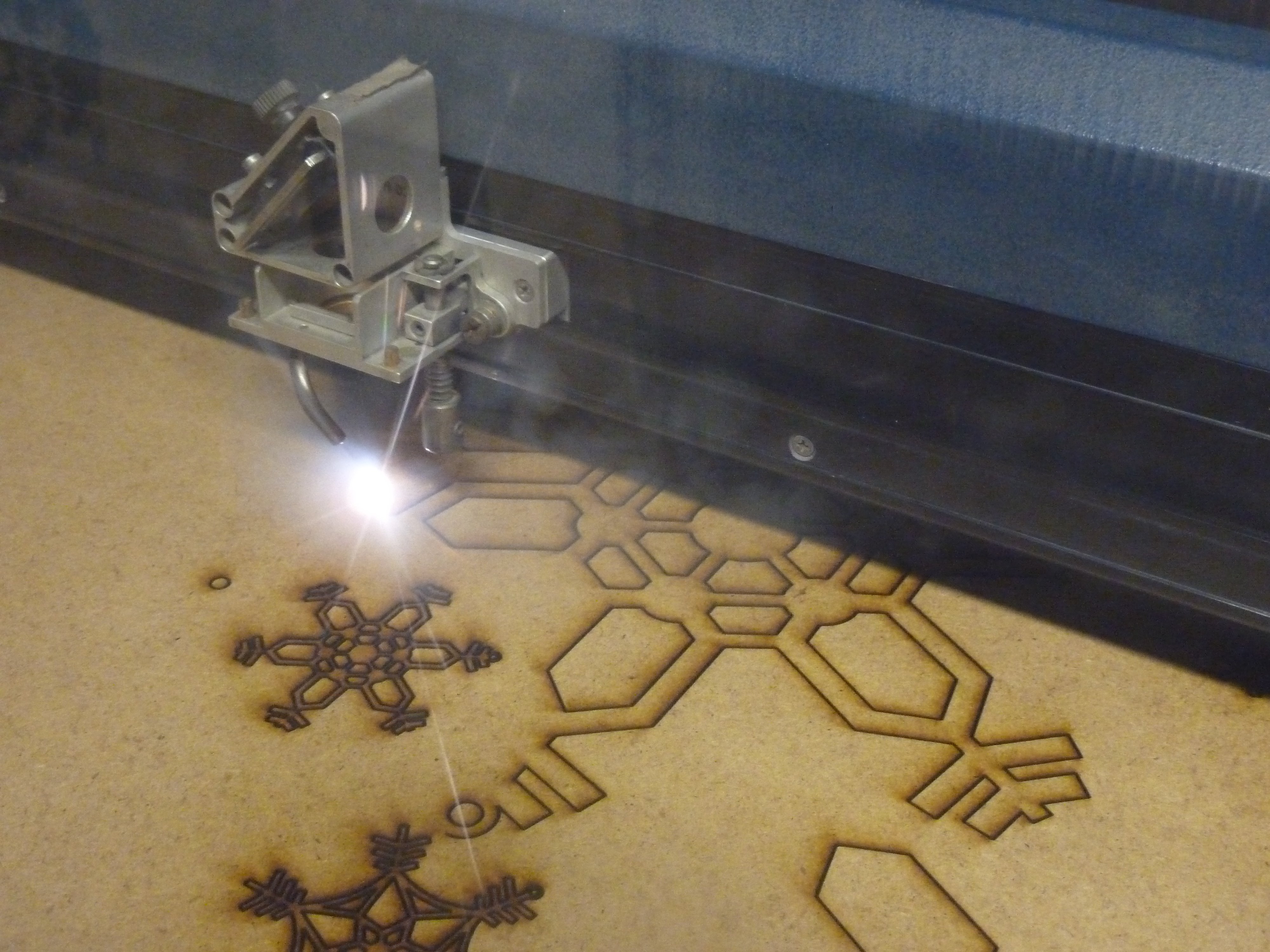

- Utilizes carbon dioxide gas to generate a high-power laser beam.

- Suitable for cutting thick MDF (up to 25mm) with high accuracy.

2. Fiber Laser Cutting:

- Employs a fiber optic cable to transmit laser energy.

- Offers faster cutting speeds and higher precision compared to CO2 laser cutting.

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Benefits of Laser Cutting MDF

Medium-density fiberboard (MDF) is a versatile material widely used in various industries, including furniture making, cabinetry, and interior design. Laser cutting has emerged as a precise and efficient method for shaping MDF into intricate designs and components. This article provides a comprehensive guide to cut MDF wooden laser cut, covering techniques, benefits, and applications.

- Wooden Laser Cut Wooden Laser Cut: A Comprehensive Guide

- Custom Cut Wood Custom Cut Wood: Precision And Perfection For Your Projects

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

H2: Laser Cutting Techniques

1. CO2 Laser Cutting:

DOWNLOAD SVG FILES FOR LASER CUTTING

- Utilizes carbon dioxide gas to generate a high-power laser beam.

- Suitable for cutting thick MDF (up to 25mm) with high accuracy.

- Precision and Accuracy: Lasers produce precise cuts with minimal deviation, resulting in high-quality finished products.

- Flexibility: Laser cutting allows for the creation of complex designs and intricate patterns.

- Speed and Efficiency: Lasers cut MDF quickly and efficiently, reducing production time and costs.

- Minimal Waste: Laser cutting minimizes material waste by optimizing cutting paths and reducing scrap.

- Clean and Precise Cuts: Lasers produce clean, burr-free cuts that require minimal post-processing.

- Furniture Making: Laser-cut MDF is used in the production of furniture components, such as cabinet doors, drawers, and decorative accents.

- Cabinetry: MDF laser cutting is ideal for creating custom cabinetry with unique designs and precise fit.

- Interior Design: Laser-cut MDF can be used to create decorative wall panels, ceiling tiles, and other interior design elements.

- Signage and Display: Laser-cut MDF is used in the production of signs, displays, and exhibition materials.

- Craft and Hobby: Laser-cut MDF is a versatile material for DIY projects, such as model making, jewelry making, and home décor.

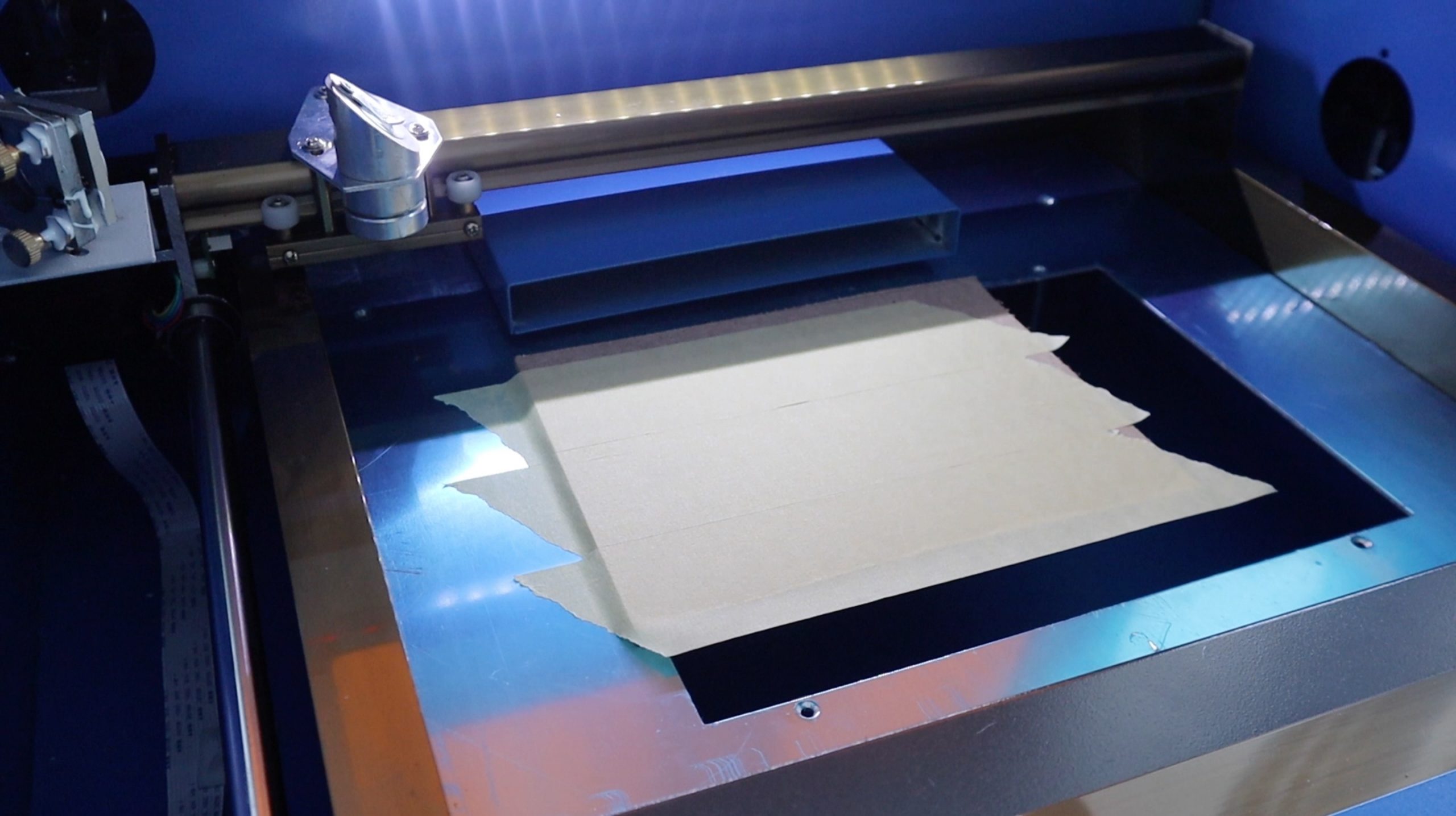

- Material Thickness: The thickness of the MDF will determine the appropriate laser cutting technique and power settings.

- Laser Power: The laser power should be sufficient to cut through the MDF cleanly and efficiently.

- Ventilation: Adequate ventilation is essential to remove fumes and dust generated during laser cutting.

- Safety Precautions: Wear appropriate safety gear, including eye protection, gloves, and a respirator.

H2: Applications of Cut MDF Wooden Laser Cut

H2: Considerations for Laser Cutting MDF

H2: Conclusion

Laser cutting MDF wooden laser cut is a precise, efficient, and versatile technique that offers numerous benefits for various applications. By understanding the different laser cutting techniques, considering the factors involved, and adhering to safety precautions, manufacturers and designers can effectively utilize laser cutting to create high-quality MDF components and products.

H2: FAQs

Q: What is the maximum thickness of MDF that can be laser cut?

A: The maximum thickness of MDF that can be laser cut depends on the laser power and technique used. Typically, CO2 lasers can cut up to 25mm thick MDF, while fiber lasers offer higher cutting speeds for thinner MDF.

Q: How to ensure clean and burr-free cuts when laser cutting MDF?

A: Use a sharp laser beam, optimize cutting parameters, and minimize laser power to reduce charring and burrs.

Q: What are the safety precautions to consider when laser cutting MDF?

A: Wear appropriate safety gear, ensure adequate ventilation, and follow manufacturer’s guidelines for laser cutting operations.