Laser Cutting MDF: A Comprehensive Guide

Introduction

Laser cutting MDF (medium-density fiberboard) has revolutionized the fabrication industry, offering unparalleled precision, speed, and versatility. MDF’s unique properties make it an ideal material for laser cutting, enabling the creation of intricate designs and custom products with exceptional surface finishes.

Table of Content

- 1 Laser Cutting MDF: A Comprehensive Guide

- 1.1 Introduction

- 1.2 H1: Understanding MDF and Its Suitability for Laser Cutting

- 1.3 H2: Benefits of Laser Cutting MDF

- 1.4 H3: Laser Cutting Process for MDF

- 1.5 H1: Understanding MDF and Its Suitability for Laser Cutting

- 1.6 H2: Benefits of Laser Cutting MDF

- 1.7 H4: Optimizing Laser Cutting Parameters

- 1.8 H5: Post-Processing Techniques

- 1.9 H6: Applications of Laser-Cut MDF

- 1.10 Conclusion

H1: Understanding MDF and Its Suitability for Laser Cutting

H2: Benefits of Laser Cutting MDF

1. Precision and Accuracy: Laser cutting provides exceptional precision, allowing for precise cuts with minimal deviation. This accuracy is crucial for creating intricate designs and ensuring dimensional stability.

2. High Speed and Efficiency: Laser cutting is a fast process, enabling the production of large quantities of parts in a short amount of time. This efficiency translates into reduced production costs and faster turnaround times.

3. Versatility: Laser cutting can be used to create a wide variety of shapes, patterns, and designs in MDF. This versatility makes it suitable for various applications, from signage to cabinetry.

4. Minimal Material Waste: Laser cutting eliminates the need for manual cutting, minimizing material waste and reducing production costs.

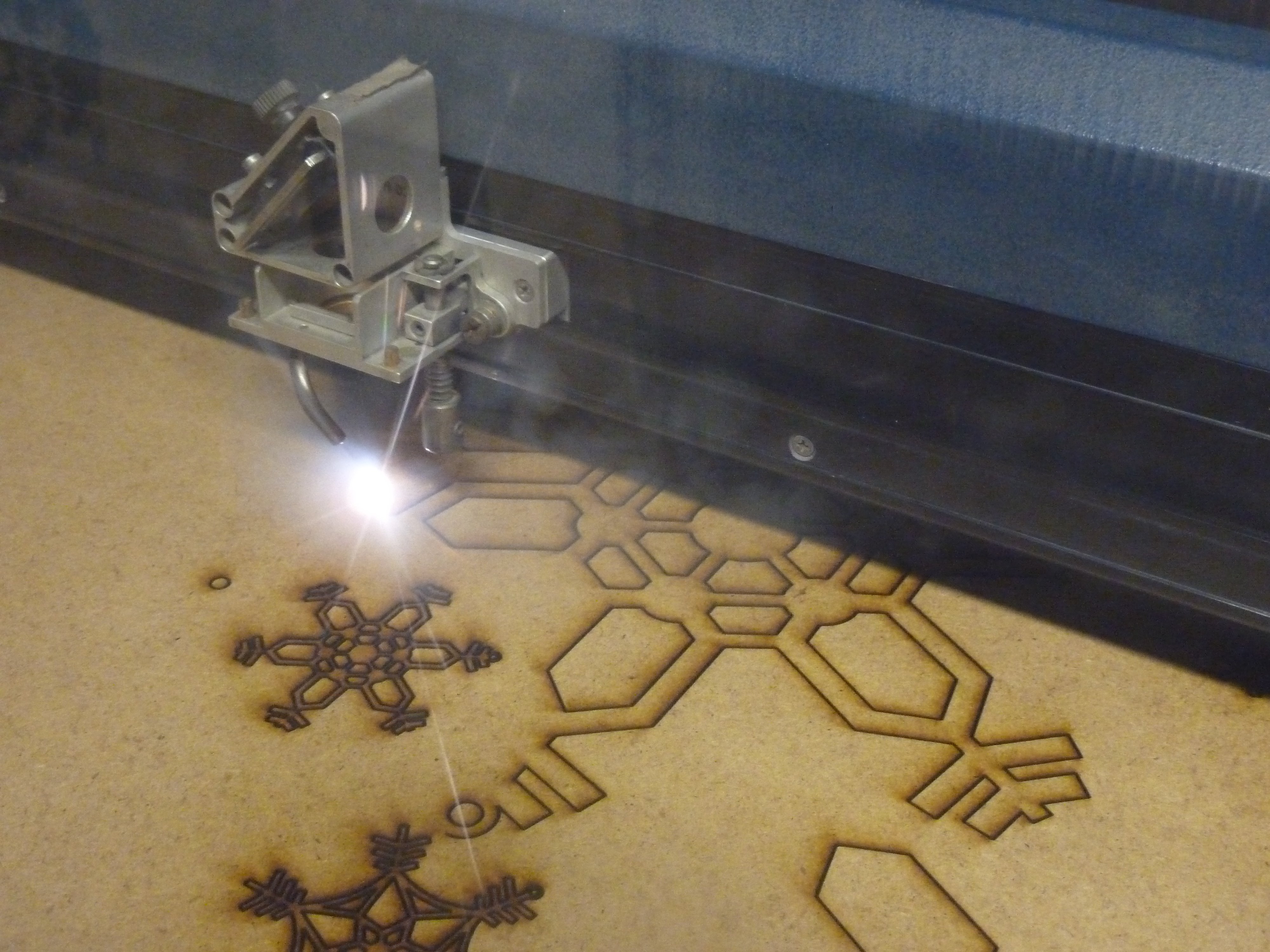

H3: Laser Cutting Process for MDF

DOWNLOAD SVG FILES FOR LASER CUTTING

1. Material Preparation: Ensure that the MDF is clean and free of any impurities or contaminants.

2. Laser Setup: Calibrate the laser cutter to the appropriate settings for MDF, including power, speed, and focus.

3. Design Import: Import the desired design into the laser cutting software and position it on the MDF.

4. Cutting: Activate the laser cutter and allow it to cut the MDF according to the specified design.

Laser cutting MDF (medium-density fiberboard) has revolutionized the fabrication industry, offering unparalleled precision, speed, and versatility. MDF’s unique properties make it an ideal material for laser cutting, enabling the creation of intricate designs and custom products with exceptional surface finishes.

- Laser Cut Wood Signs Laser Cut Wood Signs: A Comprehensive Guide

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Laser Cut Wood Panels Laser Cut Wood Panels: A Comprehensive Guide

- Laser Wood Cutter And Engraver Laser Wood Cutter And Engraver: The Ultimate Guide

H1: Understanding MDF and Its Suitability for Laser Cutting

MDF is a composite material made from wood fibers that are bonded together with resin. It possesses a uniform density, making it ideal for laser cutting as it ensures consistent results throughout the material. MDF’s high fiber content also contributes to its strength and durability.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Benefits of Laser Cutting MDF

1. Precision and Accuracy: Laser cutting provides exceptional precision, allowing for precise cuts with minimal deviation. This accuracy is crucial for creating intricate designs and ensuring dimensional stability.

2. High Speed and Efficiency: Laser cutting is a fast process, enabling the production of large quantities of parts in a short amount of time. This efficiency translates into reduced production costs and faster turnaround times.

H4: Optimizing Laser Cutting Parameters

1. Laser Power: The power of the laser determines the depth and width of the cut. Adjust the power based on the thickness of the MDF.

2. Cutting Speed: The speed of the laser affects the cut quality and edge finish. Higher speeds result in cleaner cuts, while slower speeds may produce rougher edges.

3. Focus: The focus of the laser beam determines the accuracy and precision of the cut. Ensure that the laser beam is properly focused on the MDF surface.

H5: Post-Processing Techniques

1. Sanding: Sanding the cut edges can remove any burrs or imperfections and create a smoother surface finish.

2. Painting or Finishing: MDF can be painted or finished to enhance its appearance and protect it from moisture or damage.

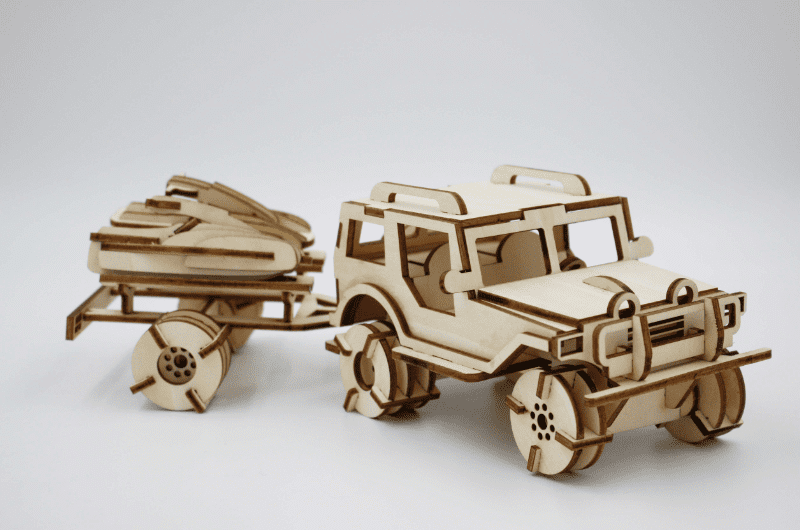

H6: Applications of Laser-Cut MDF

1. Signage: Laser-cut MDF is ideal for creating custom signage with intricate designs and lettering.

2. Furniture: MDF can be laser-cut to create furniture components, such as cabinet doors, drawer fronts, and decorative panels.

3. Packaging: Laser-cut MDF can be used to produce custom packaging solutions, such as boxes, displays, and inserts.

4. Architectural Elements: MDF can be laser-cut to create architectural elements, such as wall panels, ceiling tiles, and decorative moldings.

Conclusion

Laser cutting MDF offers numerous advantages for fabrication, including precision, speed, versatility, and minimal material waste. By understanding the material properties and optimizing the laser cutting parameters, manufacturers can achieve exceptional results. Laser-cut MDF finds applications in various industries, including signage, furniture, packaging, and architecture.