Laser Cut Timber: Unlocking Intricate Designs and Precision Manufacturing

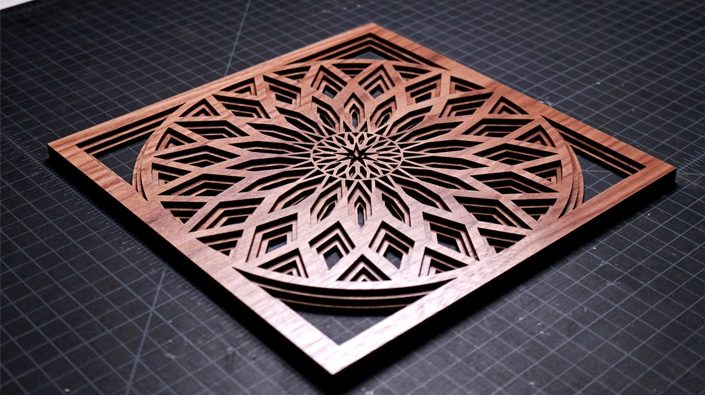

Laser cut timber, a revolutionary material in woodworking and design, has transformed the industry with its ability to produce intricate and precise patterns in wood. This innovative technology offers a wide range of applications, from architectural marvels to personalized home décor.

H1: Laser Cutting Technology for Woodworking

Table of Content

- 1 Laser Cut Timber: Unlocking Intricate Designs and Precision Manufacturing

- 1.1 H1: Laser Cutting Technology for Woodworking

- 1.2 H3: Applications of Laser Cut Timber

- 1.3 H1: Laser Cutting Technology for Woodworking

- 1.4 H2: Benefits of Laser Cut Timber

- 1.5 H2: Design Considerations for Laser Cut Timber

- 1.6 H2: Conclusion

- 1.7 FAQs

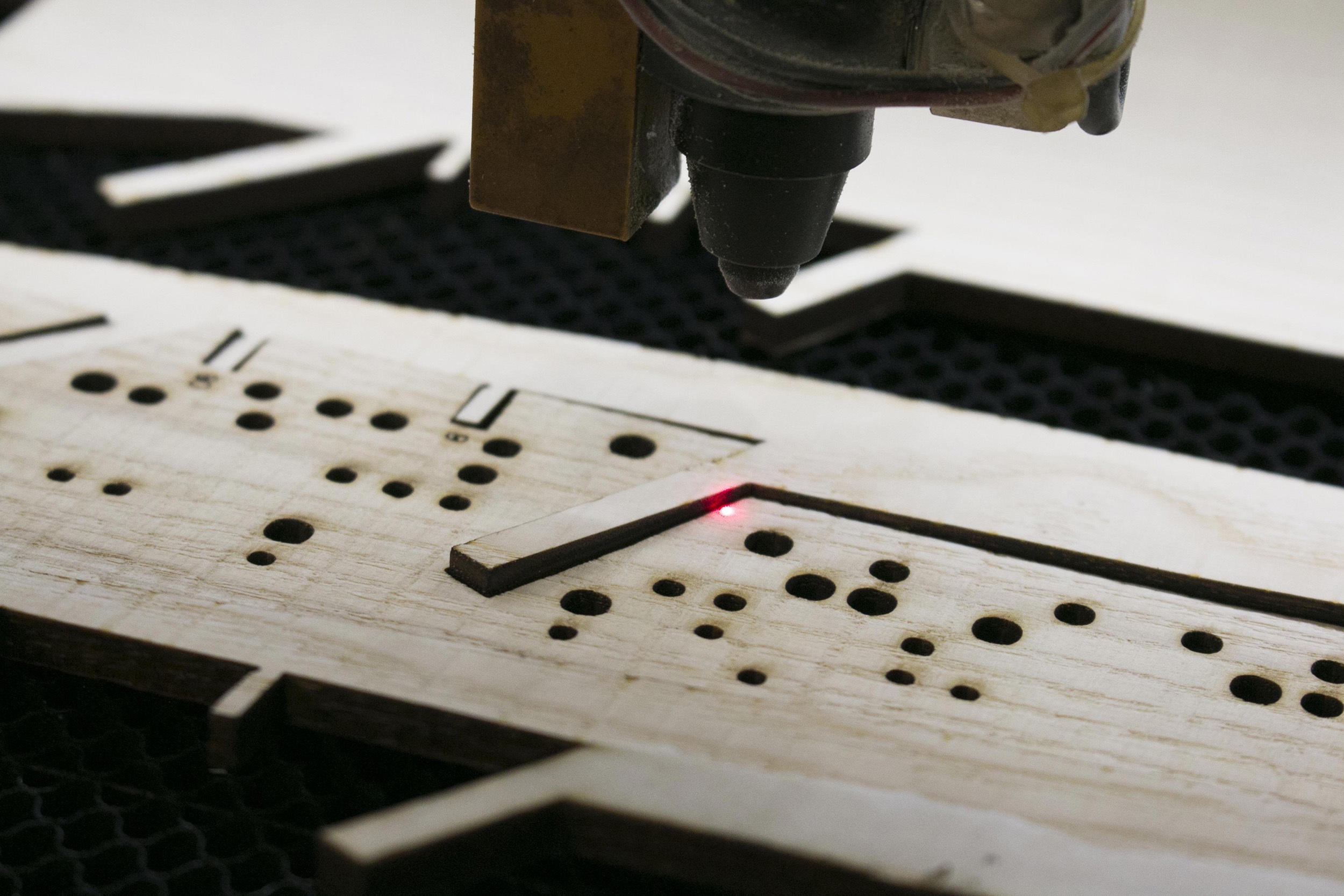

Laser cutting is a process that utilizes a high-powered laser to vaporize and cut through materials, including timber. Unlike traditional methods, laser cutting provides exceptional precision and detail, allowing for intricate designs and complex shapes. The laser beam is controlled by a computer program, ensuring accuracy and consistency in every cut.

Laser cut timber offers numerous advantages over traditional woodworking methods:

- Precision and Detail: Laser cutting produces clean and precise cuts, enabling intricate patterns and designs that would be impossible to achieve manually.

- Versatility: Laser cutters can work with a wide variety of timber species, including hardwoods, softwoods, and engineered wood products.

- Speed and Efficiency: Laser cutting is a highly efficient process that can quickly and accurately produce large quantities of cut pieces.

- Reduced Waste: Laser cutting minimizes material waste by utilizing a computer-controlled cutting process, which reduces the amount of scrap produced.

- Durability: Laser-cut timber retains its structural integrity, providing durable and long-lasting results.

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Applications of Laser Cut Timber

Laser cut timber finds applications in various industries, including:

H1: Laser Cutting Technology for Woodworking

- Laser Wood Cutting Near Me Laser Wood Cutting Near Me: A Comprehensive Guide

- Laser Engraving Wood Near Me Laser Engraving Wood Near Me: A Comprehensive Guide

- Custom Laser Cut Wood Shapes Custom Laser Cut Wood Shapes: Elevate Your Projects With Precision And Creativity

- Laser Cutting Mdf Laser Cutting MDF: A Comprehensive Guide

- Custom Cut Wood Custom Cut Wood: Precision And Perfection For Your Projects

Laser cutting is a process that utilizes a high-powered laser to vaporize and cut through materials, including timber. Unlike traditional methods, laser cutting provides exceptional precision and detail, allowing for intricate designs and complex shapes. The laser beam is controlled by a computer program, ensuring accuracy and consistency in every cut.

H2: Benefits of Laser Cut Timber

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser cut timber offers numerous advantages over traditional woodworking methods:

- Precision and Detail: Laser cutting produces clean and precise cuts, enabling intricate patterns and designs that would be impossible to achieve manually.

- Architecture: Creating decorative panels, screens, and facades with intricate designs.

- Interior Design: Producing custom-made furniture, wall art, and lighting fixtures.

- Signage and Display: Fabricating eye-catching signs, displays, and promotional materials.

- Industrial: Manufacturing precision parts, jigs, and fixtures for various industries.

- Personalized Products: Creating unique home décor items, gifts, and personalized accessories.

- Material Thickness: The thickness of the timber affects the cutting speed, precision, and overall design possibilities.

- Grain Direction: The grain direction of the timber can influence the cutting process and the appearance of the finished product.

- Laser Power and Speed: The power and speed of the laser should be adjusted to match the material thickness and design complexity.

- File Format: The design file should be in a compatible format for the laser cutter, typically DXF or AI.

- Finishing: Laser cut timber may require additional finishing, such as sanding, staining, or painting, to enhance its appearance and durability.

H2: Design Considerations for Laser Cut Timber

When designing for laser cut timber, consider the following factors:

H2: Conclusion

Laser cut timber is an innovative material that has revolutionized the woodworking industry. Its precision, versatility, and efficiency make it ideal for creating intricate designs, complex shapes, and custom-made products. As laser cutting technology continues to advance, the possibilities for laser cut timber are limitless.

FAQs

Q: What is the difference between laser cutting and CNC routing?

A: Laser cutting uses a laser beam to vaporize material, while CNC routing uses a rotating bit to cut through material. Laser cutting offers higher precision and detail, while CNC routing is more suitable for larger-scale and heavier-duty applications.

Q: Can laser cut timber be used outdoors?

A: Yes, laser cut timber can be used outdoors if it is properly treated and sealed to protect it from moisture and UV exposure.

Q: How thick can laser cut timber be?

A: The thickness of laser cut timber depends on the laser power and the type of timber used. Typically, lasers can cut through timber up to several centimeters thick.

Q: Is laser cut timber expensive?

A: The cost of laser cut timber varies depending on the size, complexity, and quantity of the project. However, laser cutting can be a cost-effective solution for small-batch production and custom-made items.