Laser Ready Wood: A Comprehensive Guide

Introduction

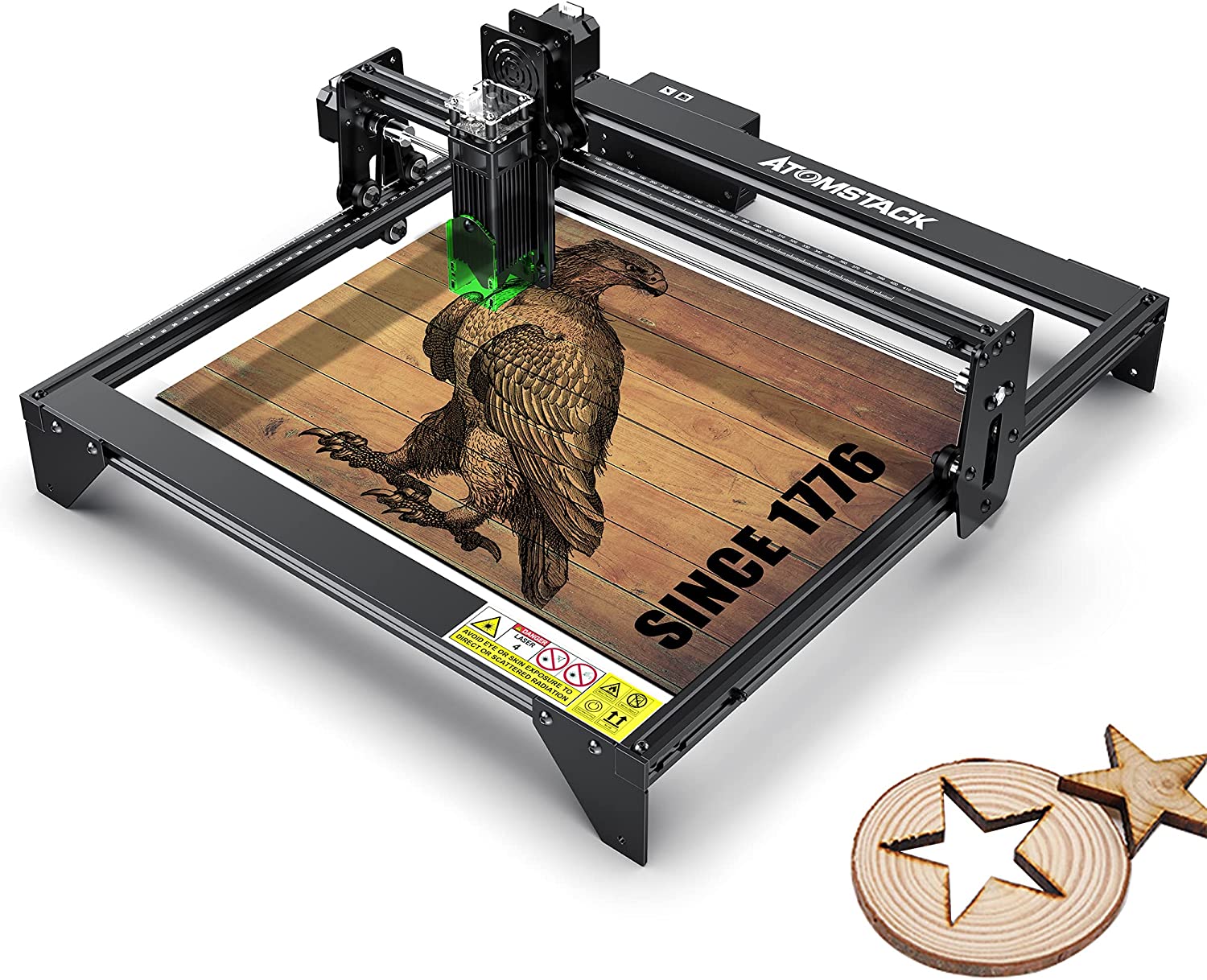

Laser engraving has become an increasingly popular technique for creating intricate designs and personalized items. Laser ready wood is a specifically engineered material that is optimized for laser engraving, providing exceptional results with minimal effort. This guide will delve into the world of laser ready wood, exploring its advantages, applications, and best practices.

Table of Content

H1: Understanding Laser Ready Wood

Laser ready wood is a type of wood that has been specially treated to enhance its compatibility with laser engraving. It typically undergoes a process of bleaching or chemical treatment to remove impurities and create a smooth, consistent surface that is ideal for laser engraving.

Advantages of Laser Ready Wood:

- Precise and Intricate Engraving: Laser ready wood allows for highly detailed and precise engraving, enabling the creation of complex designs with sharp edges and fine lines.

- Reduced Charring and Discoloration: The treated surface minimizes charring and discoloration during laser engraving, resulting in cleaner and more aesthetically pleasing results.

- Consistent Results: Laser ready wood provides consistent engraving results across different batches and pieces, ensuring uniformity and quality.

- Easy to Use: Laser ready wood is designed to be easy to work with, requiring minimal preparation or sanding before engraving.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Applications of Laser Ready Wood

Laser ready wood finds applications in a wide range of industries and projects, including:

Laser engraving has become an increasingly popular technique for creating intricate designs and personalized items. Laser ready wood is a specifically engineered material that is optimized for laser engraving, providing exceptional results with minimal effort. This guide will delve into the world of laser ready wood, exploring its advantages, applications, and best practices.

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Wood Laser Printing H1: Wood Laser Printing: A Comprehensive Guide To Engraving And Etching On Wood

- Laser Wood Cutouts Laser Wood Cutouts: A Comprehensive Guide To Crafting Precision And Intricacy

- Laser Cut Wood Signs Laser Cut Wood Signs: A Comprehensive Guide

- Laser Cutting Mdf Laser Cutting MDF: A Comprehensive Guide

H1: Understanding Laser Ready Wood

What is Laser Ready Wood?

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser ready wood is a type of wood that has been specially treated to enhance its compatibility with laser engraving. It typically undergoes a process of bleaching or chemical treatment to remove impurities and create a smooth, consistent surface that is ideal for laser engraving.

Advantages of Laser Ready Wood:

- Personalized Gifts and Home Decor: Creating custom engraved gifts, signs, plaques, and decorative items.

- Industrial Marking and Labeling: Engraving logos, serial numbers, and other markings on products and equipment.

- Art and Design: Producing intricate artwork, sculptures, and decorative pieces with laser engraving.

- Prototyping and Engineering: Rapid prototyping of parts and components using laser cutting and engraving.

- Species: Different wood species have varying densities and grain patterns that affect the engraving results.

- Thickness: The thickness of the wood will determine the depth and detail of the engraving.

- Surface Quality: Opt for laser ready wood with a smooth and consistent surface for optimal engraving results.

- Intended Application: Consider the specific application and desired aesthetic when choosing the appropriate wood species and thickness.

- Use a High-Quality Laser: Invest in a laser engraver that is calibrated and maintained for optimal performance.

- Adjust Laser Settings: Fine-tune the laser power, speed, and focus to achieve the desired engraving depth and detail.

- Prepare the Wood: Clean and dry the laser ready wood to ensure a smooth and clean engraving surface.

- Use Proper Ventilation: Laser engraving produces fumes, so ensure adequate ventilation to protect yourself and your workspace.

- Experiment with Different Settings: Test different laser settings on scrap pieces to determine the optimal parameters for your desired results.

H3: Choosing the Right Laser Ready Wood

When selecting laser ready wood, consider the following factors:

H4: Best Practices for Laser Engraving Laser Ready Wood

H5: Conclusion

Laser ready wood is an essential material for achieving high-quality laser engraving results. Its advantages, such as precise engraving, reduced charring, and consistent results, make it the ideal choice for a wide range of applications. By understanding the properties of laser ready wood, choosing the right material, and following best practices, you can unleash the full potential of laser engraving and create stunning and personalized designs.

FAQs

Q: What is the difference between laser ready wood and regular wood?

A: Laser ready wood undergoes a special treatment to remove impurities and create a smooth surface, which optimizes it for laser engraving and minimizes charring.

Q: Can I use any type of wood for laser engraving?

A: While you can technically laser engrave any type of wood, laser ready wood is specifically designed for this purpose and provides the best results.

Q: How do I determine the correct laser settings for laser ready wood?

A: Start with the manufacturer’s recommended settings and experiment with different power, speed, and focus settings on scrap pieces to find the optimal parameters for your desired results.

Q: What are some tips for getting the best engraving results on laser ready wood?

A: Use a high-quality laser, prepare the wood properly, experiment with different settings, and ensure adequate ventilation during engraving.