CNC Laser for Wood: A Comprehensive Guide

Introduction

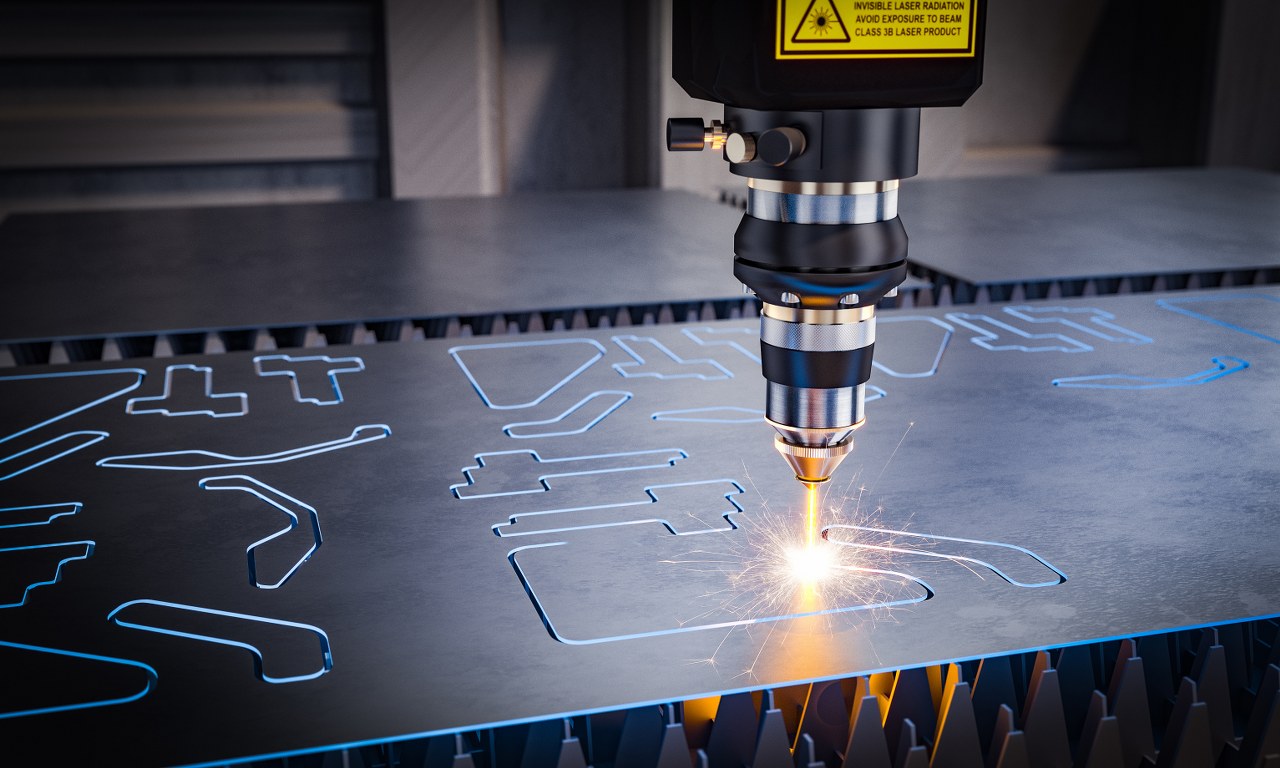

CNC (Computer Numerical Control) laser cutting has revolutionized the woodworking industry, enabling precise and efficient fabrication of intricate designs and complex shapes. CNC laser machines utilize a focused laser beam to cut, engrave, and mark wood, offering unparalleled accuracy and repeatability.

Table of Content

- 1 CNC Laser for Wood: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Understanding CNC Laser Cutting

- 1.3 Advantages of CNC Laser Cutting for Wood

- 1.4 Understanding CNC Laser Cutting

- 1.5 Applications of CNC Laser Cutting in Woodworking

- 1.6 Choosing the Right CNC Laser for Wood

- 1.7 Safety Considerations for CNC Laser Cutting

- 1.8 Conclusion

- 1.9 FAQs

Understanding CNC Laser Cutting

A CNC laser cutter consists of a laser source, a cutting head, and a computer-controlled system. The laser source generates a high-power beam that is directed through the cutting head and focused onto the workpiece. The cutting head moves along the programmed path, precisely guiding the laser beam to cut or engrave the desired design.

Types of Lasers:

- CO2 Lasers: Most commonly used for wood cutting due to their high power and ability to cut thick materials.

- Fiber Lasers: Newer technology that offers faster cutting speeds and improved efficiency.

- Diode Lasers: Suitable for delicate engraving and marking applications.

Advantages of CNC Laser Cutting for Wood

- Precision and Accuracy: Laser cutting eliminates manual errors, ensuring consistent and precise cuts every time.

- Laser Wood Cutter Near Me Laser Wood Cutter Near Me: A Comprehensive Guide

- Laser Ready Wood Laser Ready Wood: A Comprehensive Guide

- Best Wood Laser Engraver Best Wood Laser Engraver: A Comprehensive Guide To Choosing The Perfect Machine

- Laser Engraving Wood Near Me Laser Engraving Wood Near Me: A Comprehensive Guide

- Laser Cut Wood Signs Laser Cut Wood Signs: A Comprehensive Guide

- Intricate Designs: CNC lasers can execute complex designs with ease, allowing for intricate patterns and intricate details.

- Efficiency and Speed: Automated cutting processes significantly reduce production time compared to traditional methods.

- Versatility: CNC lasers can cut a wide range of wood species, from hardwoods to softwoods, and thicknesses.

- Clean and Precise Cuts: Laser cutting produces clean, burr-free edges, eliminating the need for additional sanding or finishing.

- Furniture Manufacturing: Precision cutting of intricate furniture components, such as table legs, chair backs, and decorative elements.

- Cabinetry and Millwork: Fabrication of custom cabinetry, door panels, moldings, and other architectural elements.

- Signs and Displays: Creation of eye-catching signs, logos, and promotional materials from wood.

- Toys and Games: Production of wooden toys, puzzles, and game pieces with precise shapes and intricate details.

- Art and Crafts: Engraving and cutting wood for artistic projects, such as sculptures, wall hangings, and decorative items.

- Laser Power: Higher power lasers can cut thicker materials and achieve faster cutting speeds.

- Cutting Area: Determine the size of the workpiece you will be cutting and choose a machine with an appropriate cutting area.

- Material Thickness: Consider the thickness of the wood you will be working with and ensure the laser has sufficient power to cut through it.

- Features and Accessories: Additional features, such as autofocus systems, fume extraction, and rotary attachments, can enhance efficiency and versatility.

- Software Compatibility: Ensure the machine is compatible with your preferred design software.

- Laser Safety: Wear appropriate protective eyewear and clothing to prevent laser radiation exposure.

- Fume Extraction: Use a fume extractor to remove harmful fumes generated during laser cutting.

- Fire Prevention: Keep a fire extinguisher nearby and ensure the machine is placed in a well-ventilated area.

- Electrical Safety: Follow proper electrical connections and grounding procedures to prevent electrical hazards.

CNC (Computer Numerical Control) laser cutting has revolutionized the woodworking industry, enabling precise and efficient fabrication of intricate designs and complex shapes. CNC laser machines utilize a focused laser beam to cut, engrave, and mark wood, offering unparalleled accuracy and repeatability.

Understanding CNC Laser Cutting

How it Works:

DOWNLOAD SVG FILES FOR LASER CUTTING

A CNC laser cutter consists of a laser source, a cutting head, and a computer-controlled system. The laser source generates a high-power beam that is directed through the cutting head and focused onto the workpiece. The cutting head moves along the programmed path, precisely guiding the laser beam to cut or engrave the desired design.

Types of Lasers:

Applications of CNC Laser Cutting in Woodworking

Choosing the Right CNC Laser for Wood

Safety Considerations for CNC Laser Cutting

Conclusion

CNC laser cutting has become an essential tool in the woodworking industry, enabling the production of precise, intricate, and efficient wood products. Understanding the principles, advantages, and applications of CNC laser cutting empowers woodworkers to unlock the full potential of this technology and create innovative and high-quality projects.

FAQs

Q: Can CNC lasers cut all types of wood?

A: Yes, CNC lasers can cut a wide range of wood species, including hardwoods, softwoods, and engineered wood products.

Q: What is the difference between engraving and cutting with a CNC laser?

A: Engraving involves etching a design onto the surface of the wood, while cutting involves cutting through the material to create a shape or pattern.

Q: How do I maintain my CNC laser machine?

A: Regular maintenance includes cleaning optics, lubricating moving parts, and checking for any loose connections or damage.

Q: Can I use my own designs with a CNC laser cutter?

A: Yes, most CNC laser machines are compatible with popular design software, allowing you to import and cut your own custom designs.

Q: Is it difficult to operate a CNC laser cutter?

A: With proper training and guidance, operating a CNC laser cutter is relatively straightforward. Most machines come with user-friendly software that simplifies the cutting process.