Lasercutter Wood: A Comprehensive Guide to Materials and Applications

Introduction

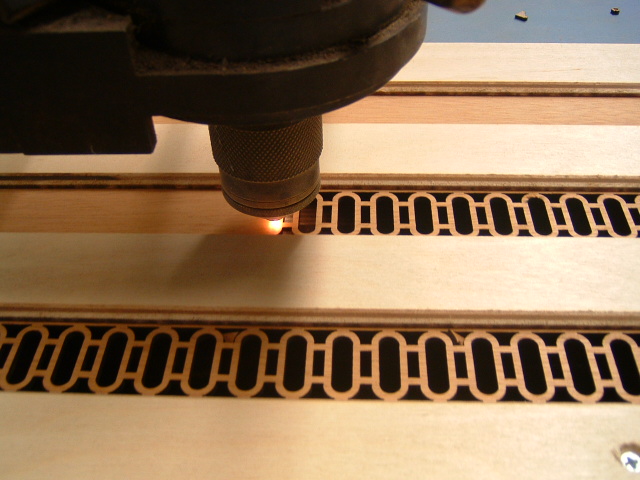

Laser cutting is a versatile and efficient method for shaping and engraving wood, offering intricate designs and precise cuts. Understanding the types of wood suitable for laser cutting and their specific properties is crucial for achieving optimal results. This guide provides an in-depth exploration of lasercutter wood, covering materials, applications, and best practices.

Table of Content

- 1 Lasercutter Wood: A Comprehensive Guide to Materials and Applications

- 1.1 Introduction

- 1.2 Materials for Laser Cutting Wood

- 1.3 Materials for Laser Cutting Wood

- 1.4 Selecting the Right Wood for Laser Cutting

- 1.5 Applications of Lasercutter Wood

- 1.6 Best Practices for Laser Cutting Wood

- 1.7 Troubleshooting Common Issues

- 1.8 Conclusion

- 1.9 FAQs

Materials for Laser Cutting Wood

- Composition: Thin layers of wood glued together

- Advantages: Strong, durable, and cost-effective

- Applications: Furniture, cabinets, toys, and decorative items

2. MDF (Medium-Density Fiberboard)

DOWNLOAD SVG FILES FOR LASER CUTTING

- Composition: Wood fibers compressed and bonded with resin

- Advantages: Smooth surface, easy to cut, and paintable

- Applications: Cabinetry, shelving, and prototyping

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

- Best Laser For Wood Engraving Best Laser For Wood Engraving: A Comprehensive Guide To Choosing The Right Tool

- Laser Cut Wood Panels Near Me Laser Cut Wood Panels Near Me: A Comprehensive Guide

- Laser To Engrave Wood Laser Engraving Wood: A Comprehensive Guide

- Best Laser Wood Cutter Best Laser Wood Cutter: A Comprehensive Guide

- Composition: Thin layers of wood glued together

- Advantages: Strong, durable, and cost-effective

- Composition: Solid wood from deciduous trees

- Advantages: Durable, attractive grain, and high-quality finish

- Applications: Furniture, flooring, and musical instruments

- Composition: Solid wood from coniferous trees

- Advantages: Lightweight, easy to work with, and affordable

- Applications: Framing, construction, and outdoor furniture

- Composition: Manufactured wood products such as veneer, laminate, and particle board

- Advantages: Durable, customizable, and eco-friendly

- Applications: Countertops, flooring, and cabinetry

- Grain: The direction and pattern of the wood grain can affect the cut quality and appearance.

- Density: Dense woods require higher laser power and slower speeds.

- Thickness: Thicker woods may require multiple passes or a higher laser power.

- Finish: The surface finish of the wood can impact the laser’s ability to cut cleanly.

- Moisture Content: High moisture content can cause the wood to warp or burn during cutting.

- Cabinets, tables, chairs, and other furniture

- Wall art, decorative panels, and sculptures

- Signage, displays, and point-of-sale materials

- Packaging, crates, and shipping containers

- Jewelry, toys, and hobby projects

- Intricate carvings, engravings, and inlays

- 3D models, architectural prototypes, and product designs

- Rapid prototyping for industrial applications

- Use a sharp laser beam: A dull beam can result in poor cut quality and excessive smoke.

- Set appropriate laser parameters: Adjust power, speed, and focus based on the wood type and thickness.

- Use proper ventilation: Laser cutting wood produces fumes and smoke, so adequate ventilation is essential.

- Secure the wood: Clamp or hold the wood in place to prevent movement during cutting.

- Clean the wood: Remove any dirt or debris from the surface before cutting.

- Test the settings: Always perform test cuts on scrap wood to optimize the parameters before cutting the final piece.

- Reduce laser power or increase cutting speed.

- Ensure proper ventilation to remove smoke.

- Check the laser beam for sharpness.

- Adjust laser parameters to optimize the cut quality.

- Use dry wood with low moisture content.

- Clamp or secure the wood firmly during cutting.

- Increase ventilation to remove fumes.

- Clean the laser cutting machine regularly.

Laser cutting is a versatile and efficient method for shaping and engraving wood, offering intricate designs and precise cuts. Understanding the types of wood suitable for laser cutting and their specific properties is crucial for achieving optimal results. This guide provides an in-depth exploration of lasercutter wood, covering materials, applications, and best practices.

Materials for Laser Cutting Wood

1. Plywood

DOWNLOAD SVG FILES FOR LASER CUTTING

3. Hardwood

4. Softwood

5. Engineered Wood

Selecting the Right Wood for Laser Cutting

The choice of wood for laser cutting depends on the desired application and aesthetics. Here are some key factors to consider:

Applications of Lasercutter Wood

Lasercutter wood finds applications in various industries, including:

1. Furniture and Home Decor:

2. Industrial and Commercial:

3. Arts and Crafts:

4. Prototyping and Modeling:

Best Practices for Laser Cutting Wood

To ensure optimal results when laser cutting wood, follow these best practices:

Troubleshooting Common Issues

1. Burned or Discolored Edges:

2. Rough or Uneven Cuts:

3. Warping or Bowing:

4. Smoke or Fumes:

Conclusion

Laser cutting wood is a powerful tool that offers versatility, precision, and efficiency. By selecting the appropriate wood type and following best practices, you can achieve high-quality results and create a wide range of applications. This guide provides a comprehensive understanding of lasercutter wood, enabling you to make informed decisions and optimize your laser cutting projects.

FAQs

1. Can I laser cut any type of wood?

Yes, but some woods are more suitable than others. Plywood, MDF, and hardwood are commonly used for laser cutting.

2. How thick can I laser cut wood?

The maximum thickness depends on the laser’s power and the wood type. Most laser cutters can handle thicknesses up to 1/4 inch.

3. What are the safety precautions for laser cutting wood?

Always wear appropriate safety gear, including eye protection and a respirator. Ensure proper ventilation and never leave the laser unattended during operation.

4. How do I clean my laser cutting machine after cutting wood?

Use a soft brush or cloth to remove any debris or residue from the laser head, mirrors, and cutting bed.