Laser Engraving on Wood: A Comprehensive Guide to Crafting Precision Designs

Introduction

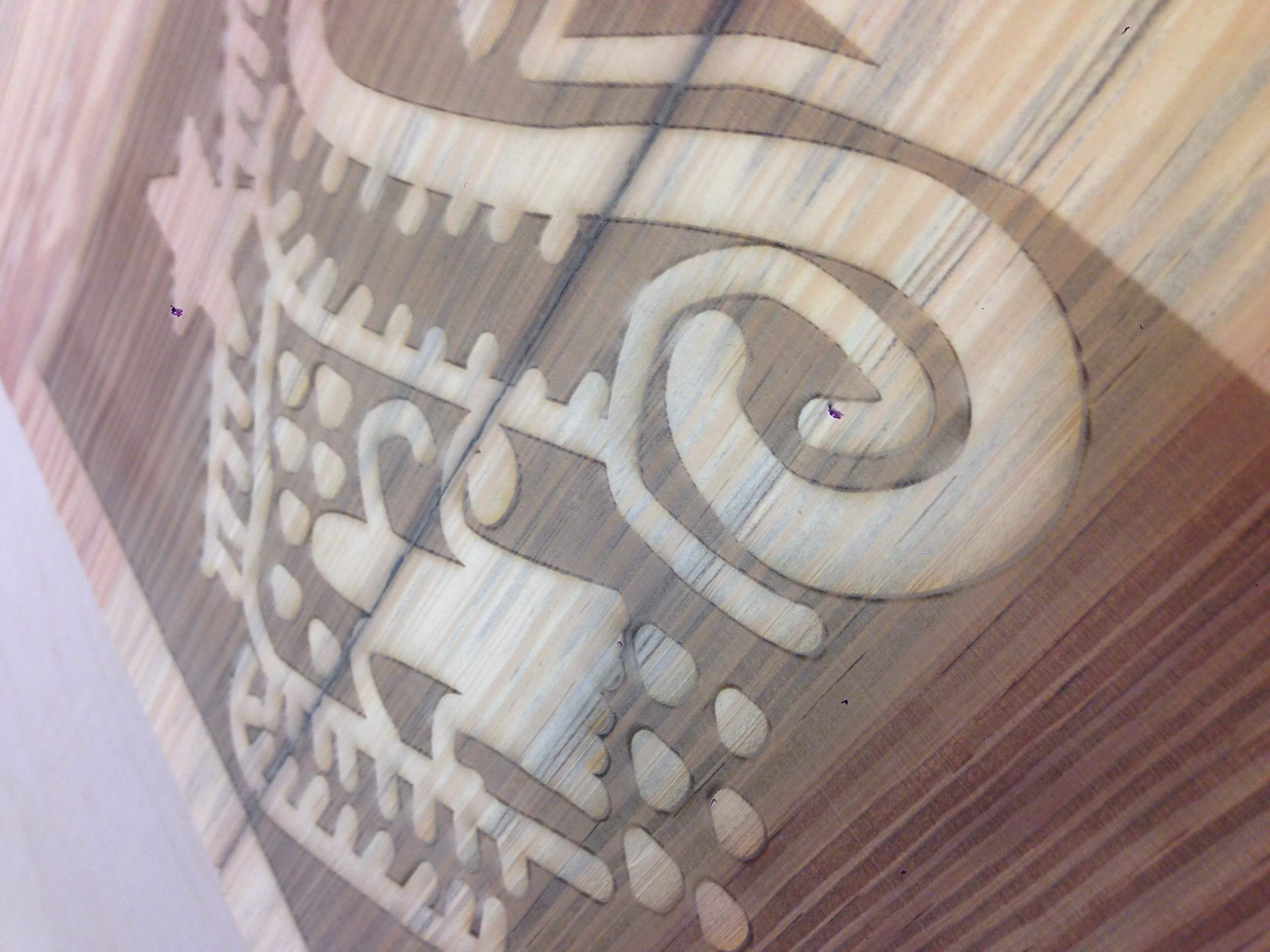

Laser engraving on wood has become an increasingly popular technique for creating intricate and precise designs on various wooden surfaces. This technology offers a wide range of possibilities for artists, crafters, and businesses alike. This comprehensive guide will delve into the intricacies of laser engraving on wood, providing detailed information on the process, techniques, and applications.

Table of Content

- 1 Laser Engraving on Wood: A Comprehensive Guide to Crafting Precision Designs

- 1.1 Introduction

- 1.2 H1: Understanding Laser Engraving Technology

- 1.3 H1: Preparing the Wood for Engraving

- 1.4 H1: Understanding Laser Engraving Technology

- 1.5 H1: Designing and Setting Up the Laser Engraver

- 1.6 H1: Engraving the Wood

- 1.7 H1: Applications of Laser Engraving on Wood

- 1.8 H2: Advantages and Limitations of Laser Engraving on Wood

- 1.9 H1: Conclusion

- 1.10 FAQs

H1: Understanding Laser Engraving Technology

H2: Types of Lasers Used in Wood Engraving

- CO2 Lasers: Commonly used for wood engraving due to their high power and long wavelength, which allows for deep engraving.

- Fiber Lasers: Newer technology that offers higher precision and faster engraving speeds.

- Diode Lasers: Smaller and more affordable lasers suitable for shallow engraving.

DOWNLOAD SVG FILES FOR LASER CUTTING

H1: Preparing the Wood for Engraving

H2: Choosing the Right Wood

- Hardwoods (e.g., oak, mahogany) are more durable and produce finer details.

- Cnc Laser Wood Cutter CNC Laser Wood Cutter: A Comprehensive Guide

- Best Wood For Glowforge Best Wood For Glowforge: A Comprehensive Guide To Choosing The Perfect Material

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

- Laser Wood Signs Laser Wood Signs: A Comprehensive Guide To Crafting Custom Masterpieces

- Laser Ready Wood Laser Ready Wood: A Comprehensive Guide

- CO2 Lasers: Commonly used for wood engraving due to their high power and long wavelength, which allows for deep engraving.

- Softwoods (e.g., pine, fir) are easier to engrave but may not offer the same level of precision.

- Sand the surface to remove any imperfections or unevenness.

- Clean the surface thoroughly to remove dirt or debris.

- Use masking tape to protect areas that should not be engraved.

- Use software to create the desired design.

- Consider the grain direction of the wood when designing.

- Convert the design to a file format compatible with the laser engraver.

- Determine the appropriate laser power and speed for the type of wood being engraved.

- Focus the laser beam to ensure precise engraving.

- Set the engraving depth and any other relevant parameters.

- Wear appropriate safety gear, including laser safety glasses.

- Place the wood in the laser engraver and secure it firmly.

- Initiate the engraving process and monitor it closely.

- Use multiple passes to achieve deeper engraving.

- Apply a wood stain or finish to highlight the engraved areas.

- Create 3D effects by varying the engraving depth.

- Create intricate wall art, sculptures, and home accessories.

- Engrave personalized photo frames, cutting boards, and coasters.

- Mark and identify wooden products for inventory control.

- Create prototypes and patterns for manufacturing.

- Engrave logos and designs on wooden packaging.

- Precision and accuracy

- Versatility in design

- Permanent and durable results

- Wide range of applications

- Can produce smoke and odor during engraving

- May require multiple passes for deep engraving

- Can be more expensive than other engraving methods

Laser engraving on wood has become an increasingly popular technique for creating intricate and precise designs on various wooden surfaces. This technology offers a wide range of possibilities for artists, crafters, and businesses alike. This comprehensive guide will delve into the intricacies of laser engraving on wood, providing detailed information on the process, techniques, and applications.

H1: Understanding Laser Engraving Technology

Laser engraving is a non-contact process that utilizes a focused beam of light to etch or cut into a material. In the case of wood engraving, a laser is used to vaporize or burn away portions of the wood surface, creating a permanent design.

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Types of Lasers Used in Wood Engraving

H2: Preparing the Wood Surface

H1: Designing and Setting Up the Laser Engraver

H2: Creating the Design

H2: Setting Up the Laser Engraver

H1: Engraving the Wood

H2: Operating the Laser Engraver

H2: Techniques for Enhancing Engraved Designs

H1: Applications of Laser Engraving on Wood

H2: Home Decor and Art

H2: Industrial Applications

H2: Advantages and Limitations of Laser Engraving on Wood

Advantages:

Limitations:

H1: Conclusion

Laser engraving on wood offers a powerful and versatile technique for creating stunning and precise designs. By understanding the technology, preparing the wood, designing and setting up the engraver, and employing appropriate techniques, artists and businesses can harness the full potential of this innovative process. From home decor to industrial applications, laser engraving on wood continues to inspire creativity and enhance the beauty and functionality of wooden surfaces.

FAQs

Q: What is the best type of laser for wood engraving?

A: CO2 lasers are the most common and versatile option. Fiber lasers offer higher precision and faster speeds, while diode lasers are suitable for shallow engraving.

Q: Can I engrave on any type of wood?

A: Yes, but hardwoods produce finer details and are more durable than softwoods.

Q: How deep can I engrave into wood?

A: The engraving depth depends on the laser power, speed, and number of passes. Typically, depths of up to 0.25 inches can be achieved.

Q: Is laser engraving on wood safe?

A: Yes, but it’s important to wear proper safety gear, including laser safety glasses. The engraving process can produce smoke and odor, so adequate ventilation should be ensured.