Laser Cut Wood Pieces: Transforming Wood into Intricate Masterpieces

Laser cutting technology has revolutionized the woodworking industry, enabling the creation of intricate and precise wood pieces that were previously impossible to achieve with traditional methods. Laser cut wood pieces offer a wide range of possibilities for various applications, from decorative home décor to functional architectural components.

Advantages of Laser Cut Wood Pieces

Table of Content

- 1 Laser Cut Wood Pieces: Transforming Wood into Intricate Masterpieces

- 1.1 Advantages of Laser Cut Wood Pieces

- 1.2 Applications of Laser Cut Wood Pieces

- 1.3 Advantages of Laser Cut Wood Pieces

- 1.4 Materials for Laser Cutting Wood

- 1.5 Process of Laser Cutting Wood

- 1.6 Design Considerations for Laser Cut Wood Pieces

- 1.7 Conclusion

- 1.8 Frequently Asked Questions (FAQs)

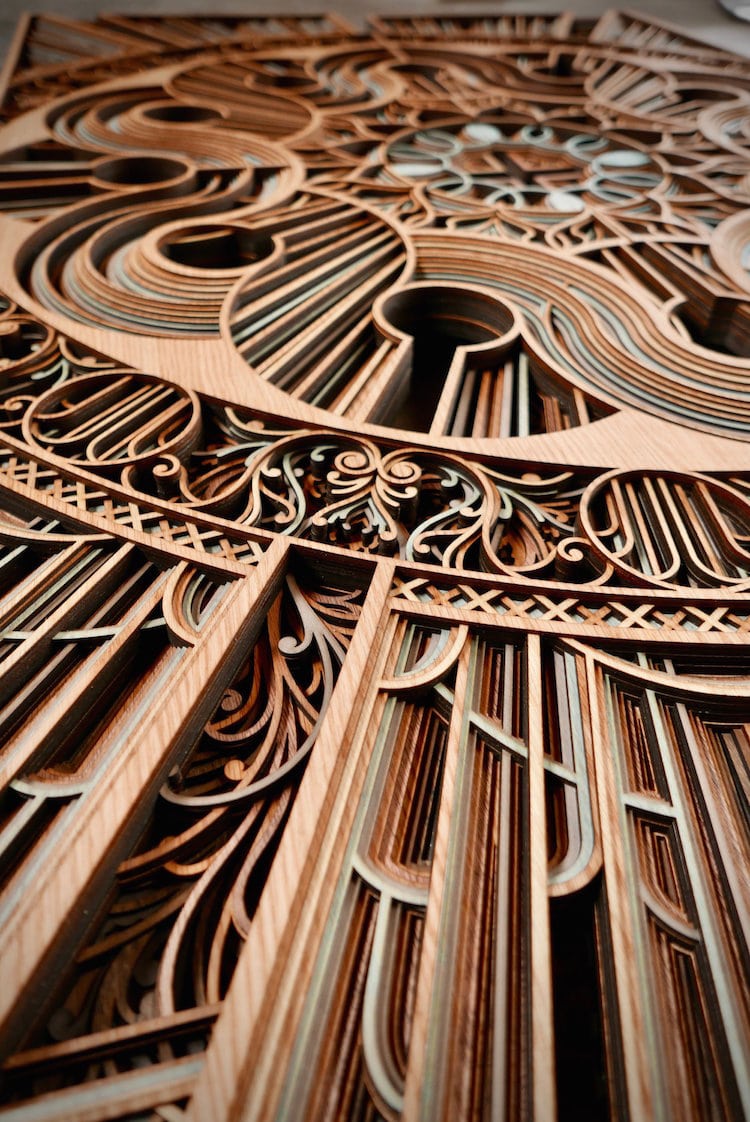

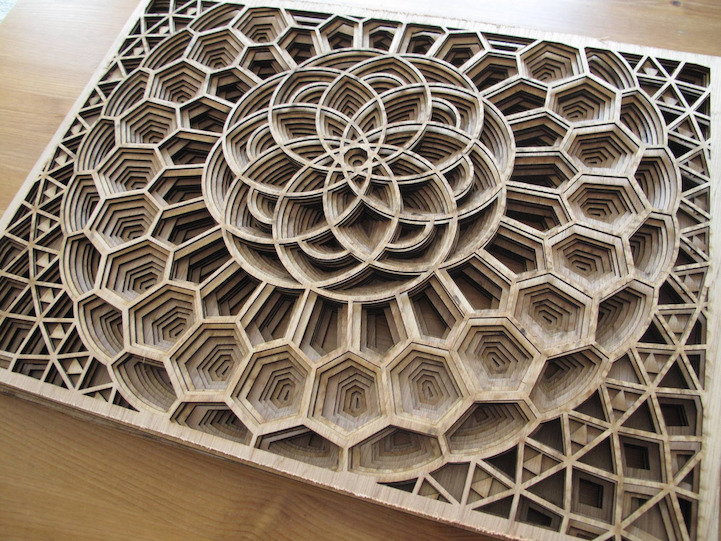

- Intricate Designs: Laser cutting allows for the creation of intricate and complex designs that would be challenging or impossible to achieve with hand tools.

- Versatility: Laser cutters can process various types of wood, including hardwoods, softwoods, and engineered wood products.

- Customization: Laser cutting enables the customization of wood pieces to meet specific requirements and design preferences.

- Speed and Efficiency: Laser cutting is a highly efficient process that can produce a large volume of wood pieces in a relatively short amount of time.

Applications of Laser Cut Wood Pieces

DOWNLOAD SVG FILES FOR LASER CUTTING

The applications of laser cut wood pieces are vast and include:

- Home Décor: Decorative wall art, coasters, table centerpieces, picture frames, and custom lighting fixtures.

- Architectural Components: Wall panels, ceiling tiles, stair treads, and decorative moldings.

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Best Wood For Glowforge Best Wood For Glowforge: A Comprehensive Guide To Choosing The Perfect Material

- Laser Cutter And Engraver For Wood Laser Cutter And Engraver For Wood: A Comprehensive Guide

- Laser Engraver For Wood Laser Engraver For Wood: A Comprehensive Guide

- Precision and Accuracy: Laser cutters utilize laser beams to cut wood with exceptional precision, resulting in clean and accurate cuts with minimal waste.

- Intricate Designs: Laser cutting allows for the creation of intricate and complex designs that would be challenging or impossible to achieve with hand tools.

- Versatility: Laser cutters can process various types of wood, including hardwoods, softwoods, and engineered wood products.

- Customization: Laser cutting enables the customization of wood pieces to meet specific requirements and design preferences.

- Toys and Games: Puzzles, building blocks, and educational toys.

- Industrial Products: Precision components, packaging materials, and custom signage.

- Art and Craft: Jewelry, sculptures, and intricate designs for various artistic projects.

- Hardwoods: Oak, mahogany, walnut, and maple offer durability and a rich grain pattern.

- Softwoods: Pine, fir, and cedar are more affordable and easier to cut, but they may have a less distinct grain.

- Engineered Wood Products: Plywood, MDF, and HDF provide dimensional stability and a smooth surface.

- Design: The desired design is created using computer-aided design (CAD) software.

- Laser Setup: The laser cutter is configured with the appropriate laser parameters, such as power, speed, and focus.

- Material Placement: The wood material is placed on the laser cutter’s bed.

- Cutting: The laser beam is directed onto the wood, cutting the material according to the design.

- Post-Processing: The cut wood pieces may undergo additional processing, such as sanding or staining, to enhance their appearance.

- Line Thickness: The thickness of the laser cut lines should be considered to ensure the structural integrity of the piece.

- Kerf Width: The kerf width, or the width of the material removed by the laser, should be taken into account when designing interlocking or fitted components.

- Material Grain: The grain pattern of the wood can affect the laser cutting process and the appearance of the finished piece.

- Laser Parameters: Adjusting laser parameters, such as power and speed, can influence the cutting quality and the efficiency of the process.

Advantages of Laser Cut Wood Pieces

DOWNLOAD SVG FILES FOR LASER CUTTING

Materials for Laser Cutting Wood

The type of wood used for laser cutting depends on the desired application and aesthetic preferences. Common materials include:

Process of Laser Cutting Wood

The laser cutting process involves several steps:

Design Considerations for Laser Cut Wood Pieces

Conclusion

Laser cut wood pieces offer a versatile and innovative way to create intricate and precise wood components for various applications. With its advantages of precision, versatility, and speed, laser cutting technology has become an essential tool for woodworkers, designers, and manufacturers. By carefully considering design factors, material selection, and laser parameters, it is possible to produce high-quality laser cut wood pieces that meet specific requirements and add value to any project.

Frequently Asked Questions (FAQs)

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness of wood that can be laser cut depends on the laser cutter’s power and the type of wood being used. Typically, most laser cutters can cut wood up to 1/2 inch in thickness.

Q: Can laser cut wood pieces be stained or painted?

A: Yes, laser cut wood pieces can be stained or painted to enhance their appearance and protect them from the elements.

Q: How do I clean laser cut wood pieces?

A: Laser cut wood pieces can be cleaned using a soft cloth or brush. Avoid using harsh chemicals or abrasive cleaners, as they may damage the surface of the wood.

Q: Can laser cut wood pieces be used outdoors?

A: Laser cut wood pieces can be used outdoors, but they should be treated with a weather-resistant sealant to protect them from moisture and UV damage.

Q: Where can I find laser cutting services?

A: Laser cutting services are offered by a variety of companies, including commercial laser cutting businesses, makerspaces, and some hardware stores.