Laser Cutting on Wood: A Comprehensive Guide for Precision and Intricacy

Introduction

Laser cutting on wood has revolutionized the woodworking industry, offering unparalleled precision and intricate design possibilities. This advanced technology has opened up new avenues for creating custom pieces, decorative accents, and functional products from a versatile and sustainable material.

Table of Content

- 1 Laser Cutting on Wood: A Comprehensive Guide for Precision and Intricacy

- 1.1 Introduction

- 1.2 H1: The Benefits of Laser Cutting on Wood

- 1.3 H2: How Laser Cutting Works

- 1.4 H3: Factors Affecting Laser Cutting Quality

- 1.5 H1: The Benefits of Laser Cutting on Wood

- 1.6 H3: Laser Cutting Applications in Woodworking

- 1.7 H3: Laser Cutting Services Near Me

- 1.8 H4: Conclusion

- 1.9 H5: FAQs

H1: The Benefits of Laser Cutting on Wood

- Precision: Laser cutters can achieve intricate cuts with tolerances of up to 0.001 inches, ensuring precise and consistent results.

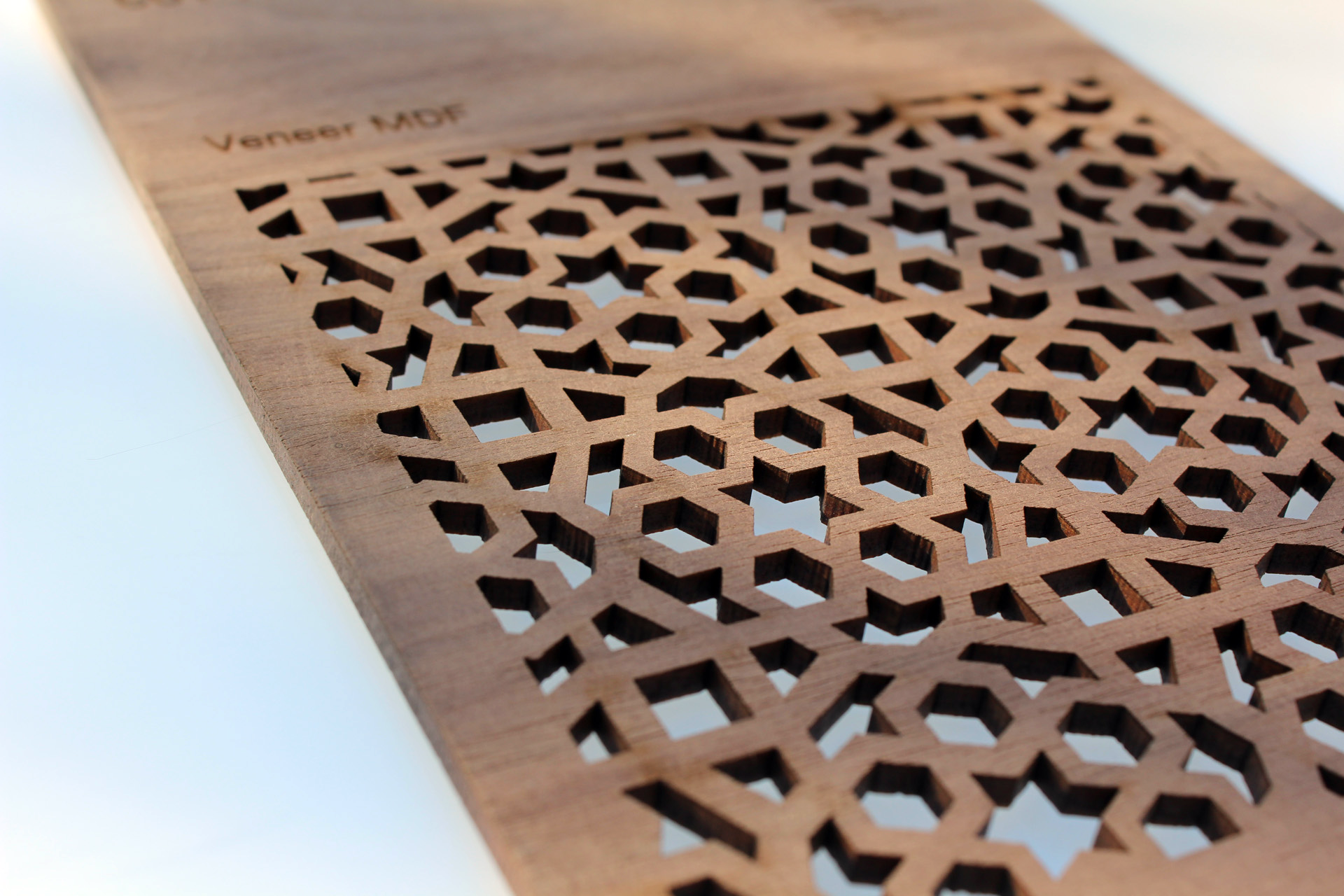

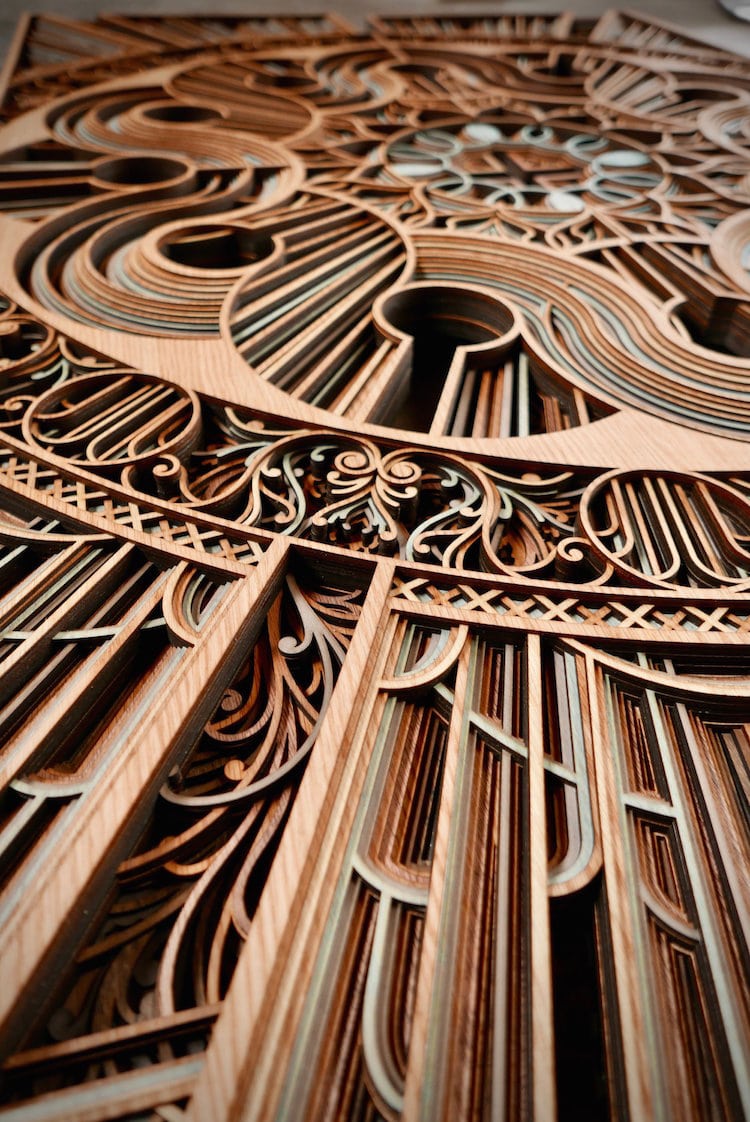

- Intricacy: Lasers enable the creation of highly detailed and complex designs, allowing for intricate patterns and fine details.

- Speed: Laser cutters operate at high speeds, significantly reducing production time compared to manual methods.

- Versatility: Laser cutting is compatible with a wide range of wood types, including hardwoods, softwoods, and plywood.

- Sustainability: Lasers minimize material waste by precisely cutting along desired lines, reducing the need for excess material.

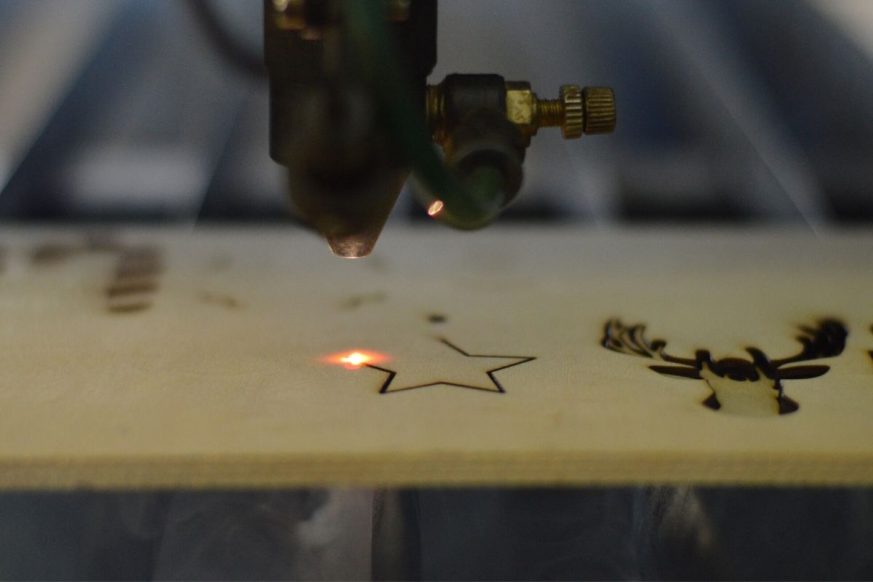

H2: How Laser Cutting Works

Laser cutting on wood involves directing a concentrated beam of light onto the wood surface. The laser’s high energy density vaporizes or burns away the material along the cutting path, creating precise and clean cuts.

H3: Factors Affecting Laser Cutting Quality

Laser cutting on wood has revolutionized the woodworking industry, offering unparalleled precision and intricate design possibilities. This advanced technology has opened up new avenues for creating custom pieces, decorative accents, and functional products from a versatile and sustainable material.

- Custom Laser Cut Wood Shapes Custom Laser Cut Wood Shapes: Elevate Your Projects With Precision And Creativity

- Best Wood For Glowforge Best Wood For Glowforge: A Comprehensive Guide To Choosing The Perfect Material

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Large Wood Laser Cutter Large Wood Laser Cutter: The Ultimate Guide For Woodworking Professionals

H1: The Benefits of Laser Cutting on Wood

Laser cutting provides numerous advantages over traditional woodworking methods, including:

DOWNLOAD SVG FILES FOR LASER CUTTING

- Precision: Laser cutters can achieve intricate cuts with tolerances of up to 0.001 inches, ensuring precise and consistent results.

- Intricacy: Lasers enable the creation of highly detailed and complex designs, allowing for intricate patterns and fine details.

- Laser Power: Higher laser power results in faster cutting speeds and cleaner cuts.

- Lens Focus: Proper lens focus ensures that the laser beam is concentrated on the desired cutting depth.

- Cutting Speed: The cutting speed determines the width and smoothness of the cut.

- Wood Type: Different wood species have varying densities and moisture content, affecting the laser cutting parameters.

- Furniture: Laser cutting enables the creation of custom furniture with intricate designs and precise joinery.

- Decorative Accents: Laser-cut wood panels, wall art, and home accessories add a touch of sophistication and elegance.

- Signage: Laser cutting produces durable and eye-catching wooden signs for businesses, organizations, and events.

- Toys and Games: Laser cutting allows for the production of intricate wooden toys and game pieces with high precision.

- Industrial Products: Laser cutting is used to create wooden components for packaging, industrial machinery, and other products.

- Online Directories: Search online directories such as Google My Business or Yelp for laser cutting businesses near your location.

- Industry Associations: Contact industry associations like the Laser Institute of America for a list of certified laser cutting service providers.

- Local Makerspaces: Many makerspaces offer laser cutting equipment and training, providing access to laser cutting services for small projects.

Several factors influence the quality of laser-cut wood products, including:

H3: Laser Cutting Applications in Woodworking

Laser cutting on wood finds diverse applications in the woodworking industry, such as:

H3: Laser Cutting Services Near Me

Finding laser cutting services near you is essential for timely and efficient project completion. Here are some tips for locating laser cutting providers in your area:

H4: Conclusion

Laser cutting on wood has become an indispensable tool for woodworkers and artisans alike. Its precision, intricacy, and speed enable the creation of exceptional wooden products that meet the demands of modern design and production. By leveraging laser cutting services near you, you can unlock the potential of this technology and elevate your woodworking projects to the next level.

H5: FAQs

Q: What is the cost of laser cutting on wood?

A: The cost varies based on factors such as the complexity of the design, material used, and quantity of cuts. Contact local laser cutting service providers for specific pricing information.

Q: Can laser cutting be used on painted or finished wood?

A: Yes, but it is important to note that the laser can burn or discolor the paint or finish. Consider masking the areas to be protected or using a laser-compatible finish.

Q: What are the safety precautions for laser cutting on wood?

A: Laser cutting involves high temperatures and hazardous fumes. Proper ventilation, protective eyewear, and appropriate clothing are essential for safety.

Q: Can laser cutting be used to engrave wood?

A: Yes, laser cutting can be used for both cutting and engraving. The laser can create shallow or deep engravings by adjusting the laser parameters.