Wood Panels for Laser Cutting: A Comprehensive Guide

Laser cutting has revolutionized the woodworking industry, offering unparalleled precision, versatility, and speed. Among the materials that excel in laser cutting, wood panels stand out for their versatility, aesthetic appeal, and ease of processing. This comprehensive guide will explore the world of wood panels for laser cutting, providing insights into the types of panels, the laser cutting process, design considerations, and best practices.

Types of Wood Panels for Laser Cutting

Table of Content

- 1 Wood Panels for Laser Cutting: A Comprehensive Guide

- 1.1 Types of Wood Panels for Laser Cutting

- 1.2 Types of Wood Panels for Laser Cutting

- 1.3 Laser Cutting Process for Wood Panels

- 1.4 Design Considerations for Laser Cutting Wood Panels

- 1.5 Best Practices for Laser Cutting Wood Panels

- 1.6 FAQs about Wood Panels for Laser Cutting

- 1.7 Conclusion

Various types of wood panels are suitable for laser cutting, each with unique characteristics and applications:

Plywood: Composed of thin layers of wood veneers glued together, plywood offers strength, stability, and a wide range of thicknesses. It is ideal for structural components, signage, and decorative applications.

Medium-Density Fiberboard (MDF): A dense, uniform material made from wood fibers, MDF provides a smooth, consistent surface. It is commonly used for cabinetry, furniture, and interior design elements.

DOWNLOAD SVG FILES FOR LASER CUTTING

High-Density Fiberboard (HDF): Similar to MDF, HDF is denser and harder, making it suitable for high-traffic areas and applications requiring durability.

Types of Wood Panels for Laser Cutting

- Cnc Laser For Wood CNC Laser For Wood: A Comprehensive Guide

- Laser Cut Wood Signs Laser Cut Wood Signs: A Comprehensive Guide

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Laser Saw For Wood Laser Saw For Wood: The Ultimate Guide To Precision Cutting

- Laser Wood Cutter Near Me Laser Wood Cutter Near Me: A Comprehensive Guide

Various types of wood panels are suitable for laser cutting, each with unique characteristics and applications:

-

Plywood: Composed of thin layers of wood veneers glued together, plywood offers strength, stability, and a wide range of thicknesses. It is ideal for structural components, signage, and decorative applications.

DOWNLOAD SVG FILES FOR LASER CUTTING

Veneered Wood Panels: These panels consist of a thin layer of real wood glued to a substrate material, offering the aesthetic appeal of natural wood with the stability of engineered panels.

Hardwood Veneers: Thin sheets of real hardwood, hardwood veneers are used to enhance the appearance of MDF or plywood, providing a luxurious and natural finish.

Laser Cutting Process for Wood Panels

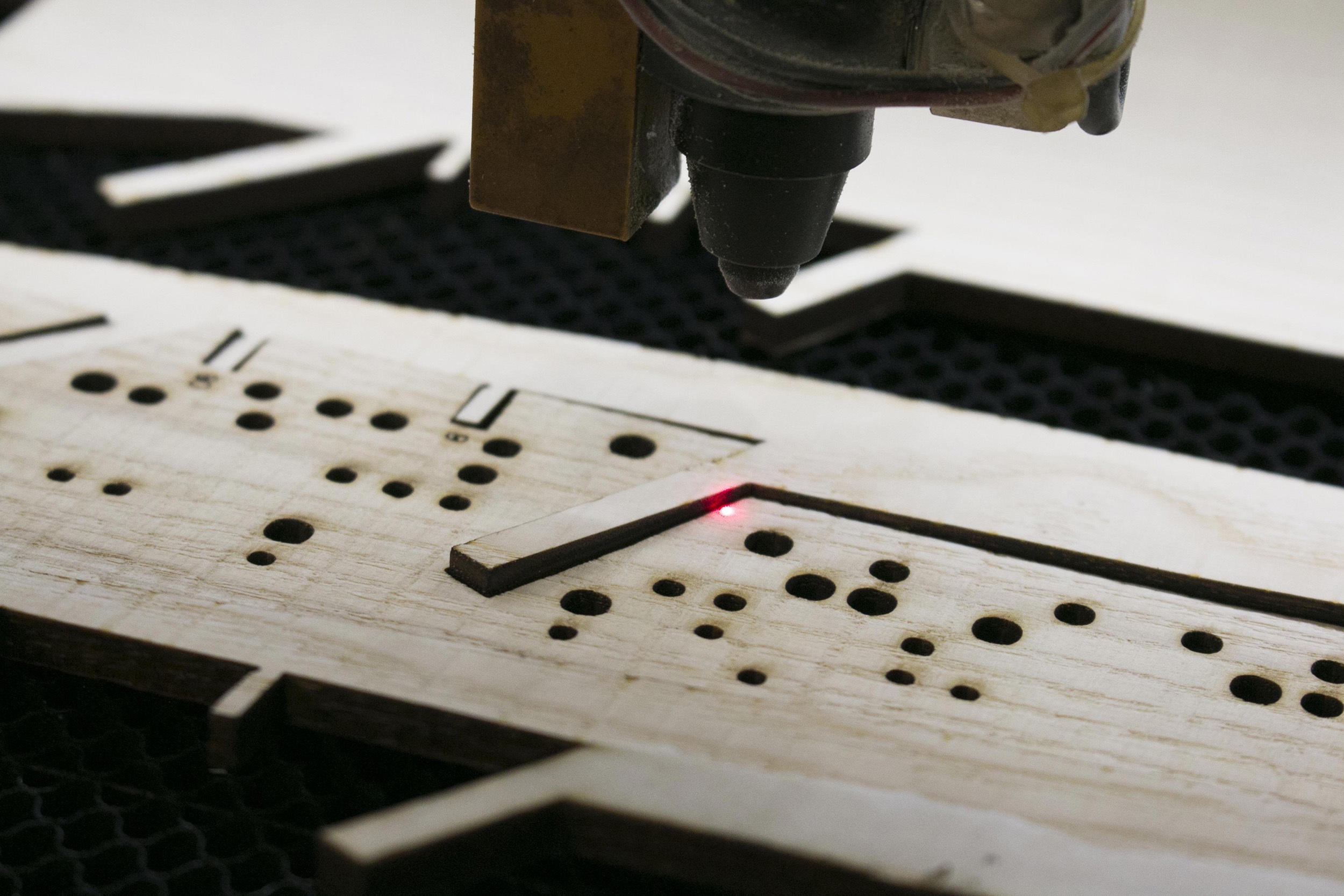

The laser cutting process involves directing a high-powered laser beam onto the wood panel, vaporizing the material and creating precise cuts. The following steps outline the general process:

-

Design Preparation: The desired design is created using a computer-aided design (CAD) software.

-

Material Selection: The appropriate type of wood panel is selected based on the desired properties and application.

-

Laser Setup: The laser cutter is calibrated to the desired cutting parameters, including power, speed, and focus.

-

Cutting: The laser beam is directed onto the wood panel, following the design path. The laser vaporizes the material, creating the desired cuts.

-

Post-Processing: After cutting, the workpiece may require additional processing, such as sanding, finishing, or assembly.

Design Considerations for Laser Cutting Wood Panels

When designing for laser cutting wood panels, several factors should be taken into account:

-

Cut Width: The laser beam has a finite width, which determines the minimum cut width achievable.

-

Kerf: The material removed during cutting is known as the kerf. It is essential to consider the kerf when designing interlocking or fitting parts.

-

Grain Direction: The grain direction of the wood can affect the cutting speed and the appearance of the cut edges.

-

Hole Size: The minimum hole size that can be cut depends on the laser power and the material thickness.

-

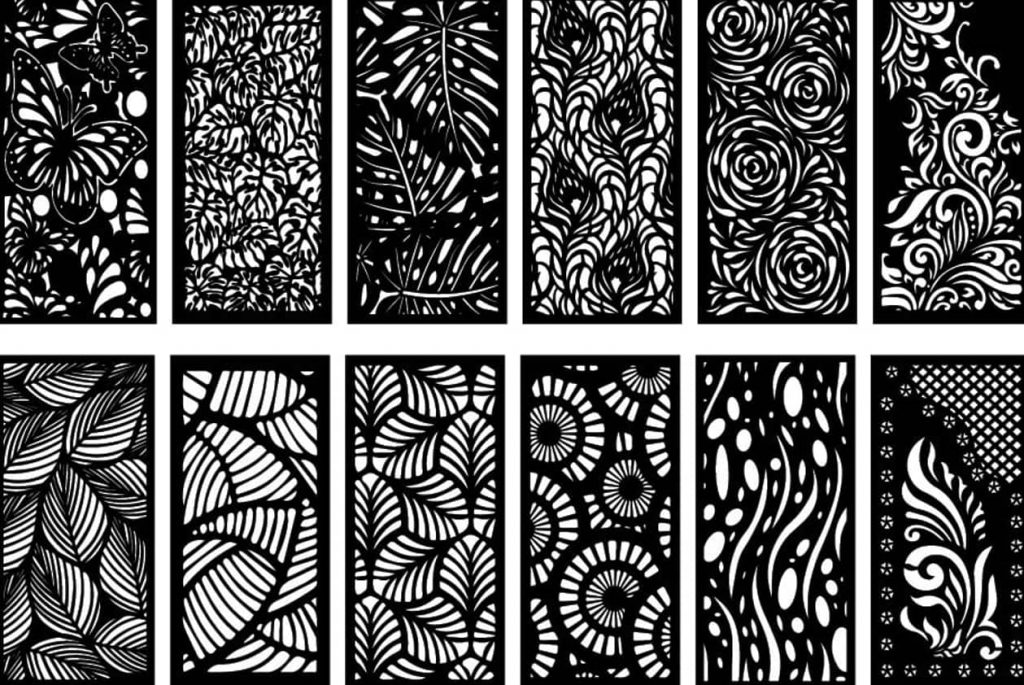

Intricate Designs: Laser cutting allows for highly intricate designs, but it is crucial to ensure that the design is compatible with the laser cutter’s capabilities.

Best Practices for Laser Cutting Wood Panels

To achieve optimal results when laser cutting wood panels, follow these best practices:

-

Use Sharp Optics: Clean and well-maintained laser optics ensure precise cuts and minimize burn marks.

-

Set Appropriate Parameters: Adjust the laser power, speed, and focus based on the material thickness and desired cut quality.

-

Control Airflow: Proper airflow helps remove debris and prevent heat buildup, resulting in cleaner cuts.

-

Test Cut: Always perform test cuts on scrap material to verify the settings and ensure desired results.

-

Secure the Material: Clamp or hold the wood panel securely to prevent movement during cutting.

-

Consider Post-Processing: Plan for any necessary post-processing steps, such as sanding, finishing, or assembling.

FAQs about Wood Panels for Laser Cutting

1. What is the best type of wood for laser cutting?

The best wood for laser cutting depends on the specific application. Plywood offers strength and stability, MDF provides a smooth surface, and hardwood veneers add aesthetic appeal.

2. What are the advantages of laser cutting wood panels?

Laser cutting offers precision, speed, versatility, and the ability to create intricate designs.

3. Can I laser cut wood panels at home?

Yes, it is possible to laser cut wood panels at home with a hobby-grade laser cutter. However, it is essential to follow safety precautions and ensure proper ventilation.

4. How thick of wood panels can I laser cut?

The maximum thickness of wood panels that can be laser cut depends on the laser power and the type of wood. Typically, laser cutters can handle thicknesses up to 0.5 inches (12.7 mm).

5. What are the applications of laser-cut wood panels?

Laser-cut wood panels are used in various applications, including furniture, cabinetry, signage, interior design, and prototyping.

Conclusion

Wood panels offer a wide range of possibilities for laser cutting, enabling the creation of intricate designs, functional components, and visually stunning pieces. By understanding the types of wood panels, the laser cutting process, design considerations, and best practices, woodworkers and designers can harness the power of laser cutting to transform their creative ideas into reality.