3D Laser Cut Wood: A Comprehensive Guide

Introduction

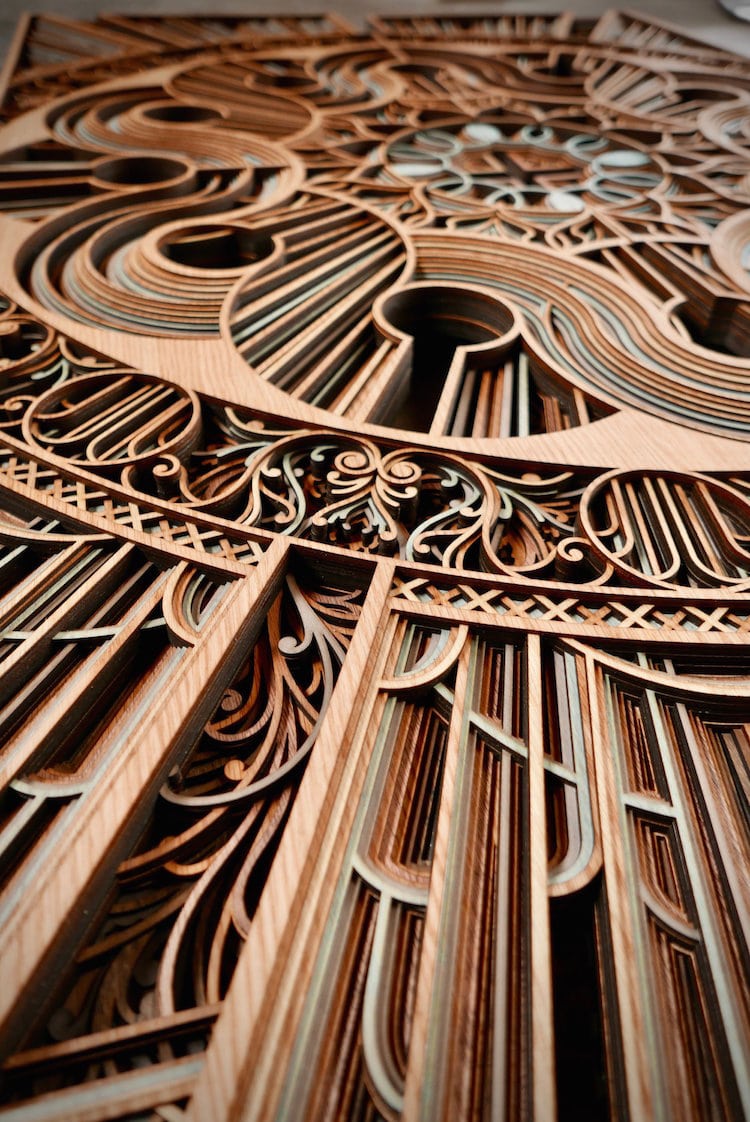

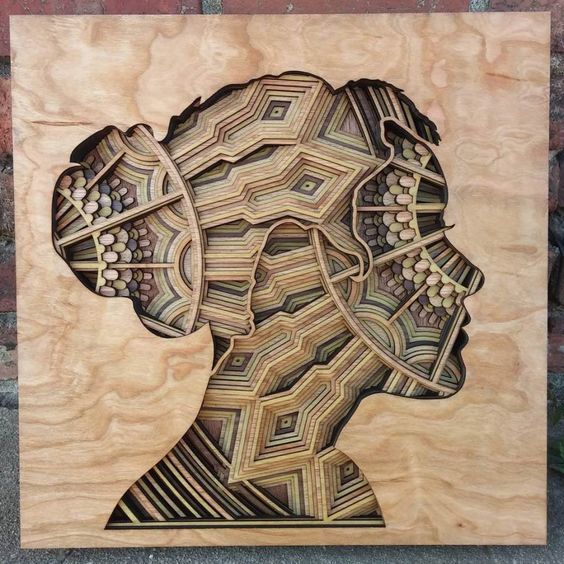

3D laser cut wood is a cutting-edge technology that has revolutionized the woodworking industry. It allows for the creation of intricate and precise three-dimensional designs from wooden materials. This article delves into the world of 3D laser cut wood, exploring its applications, advantages, and limitations.

Table of Content

- 1 3D Laser Cut Wood: A Comprehensive Guide

- 1.1 Introduction

- 1.2 How Does 3D Laser Cutting Work?

- 1.3 Applications of 3D Laser Cut Wood

- 1.4 Advantages of 3D Laser Cut Wood

- 1.5 How Does 3D Laser Cutting Work?

- 1.6 Applications of 3D Laser Cut Wood

- 1.7 Limitations of 3D Laser Cut Wood

- 1.8 Conclusion

- 1.9 FAQs

How Does 3D Laser Cutting Work?

Applications of 3D Laser Cut Wood

3D laser cut wood finds applications in a wide range of industries, including:

- Architecture: Creating custom architectural elements such as decorative panels, screens, and furniture.

- Interior Design: Designing unique wall art, lighting fixtures, and room dividers.

- Product Design: Prototyping and manufacturing products with complex geometries, such as toys, puzzles, and home accessories.

- Signage: Producing eye-catching and durable signs, logos, and branding materials.

- Jewelry and Accessories: Crafting intricate jewelry pieces, watch bands, and other accessories.

DOWNLOAD SVG FILES FOR LASER CUTTING

Advantages of 3D Laser Cut Wood

3D laser cut wood is a cutting-edge technology that has revolutionized the woodworking industry. It allows for the creation of intricate and precise three-dimensional designs from wooden materials. This article delves into the world of 3D laser cut wood, exploring its applications, advantages, and limitations.

- Cnc Laser Wood Cutter CNC Laser Wood Cutter: A Comprehensive Guide

- Small Wood Laser Cutter For Sale Small Wood Laser Cutter For Sale: A Comprehensive Guide

- Best Laser Wood Cutter For Small Business Best Laser Wood Cutter For Small Business: A Comprehensive Guide

- Cut Mdf Wooden Laser Cut H1: Cut MDF Wooden Laser Cut: A Comprehensive Guide

- Large Wood Laser Cutter Large Wood Laser Cutter: The Ultimate Guide For Woodworking Professionals

How Does 3D Laser Cutting Work?

3D laser cutting involves using a computer-controlled laser to cut wood along three axes (X, Y, and Z). The laser beam, focused through a lens, generates intense heat that vaporizes or burns away the wood, resulting in precise and clean cuts.

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of 3D Laser Cut Wood

3D laser cut wood finds applications in a wide range of industries, including:

- Precision and Detail: Laser cutting allows for precise and intricate cuts, enabling the creation of highly detailed and complex designs.

- Versatility: 3D laser cutters can work with various wood species, including hardwoods, softwoods, and engineered wood.

- Speed and Efficiency: The laser cutting process is fast and efficient, reducing production time and costs.

- Environmental Sustainability: Laser cutting is a low-waste process that minimizes material consumption and reduces environmental impact.

- Customization: 3D laser cutting allows for the customization of products to meet specific requirements and preferences.

- Material Thickness: The thickness of wood that can be cut with a laser is limited by the power of the laser and the type of wood being used.

- Charring and Discoloration: Laser cutting can cause charring or discoloration on the edges of the cut, which may require additional finishing.

- Dust and Fumes: The laser cutting process generates dust and fumes, requiring proper ventilation and dust collection systems.

- Cost: 3D laser cutting equipment and materials can be expensive, affecting the overall production costs.

Limitations of 3D Laser Cut Wood

Conclusion

3D laser cut wood is a transformative technology that offers numerous advantages for woodworking applications. Its precision, versatility, speed, and sustainability make it an ideal choice for creating intricate and unique products. While there are some limitations to consider, the benefits of 3D laser cutting outweigh the challenges, making it an indispensable tool for designers, manufacturers, and artists alike.

FAQs

Q: What is the difference between 2D and 3D laser cutting?

A: 2D laser cutting involves cutting along a flat plane, while 3D laser cutting adds the ability to cut along the Z-axis, allowing for the creation of three-dimensional objects.

Q: What file formats are compatible with 3D laser cutters?

A: Common file formats used for 3D laser cutting include STL, OBJ, and DXF.

Q: Can 3D laser cutters cut other materials besides wood?

A: Yes, 3D laser cutters can also cut a variety of other materials, including acrylic, leather, fabric, and some metals.

Q: How do I maintain a 3D laser cutter?

A: Regular maintenance of a 3D laser cutter involves cleaning the optics, adjusting the laser alignment, and replacing filters as needed.