CO2 Laser Wood Cutter: A Comprehensive Guide for Precision Cutting

Introduction

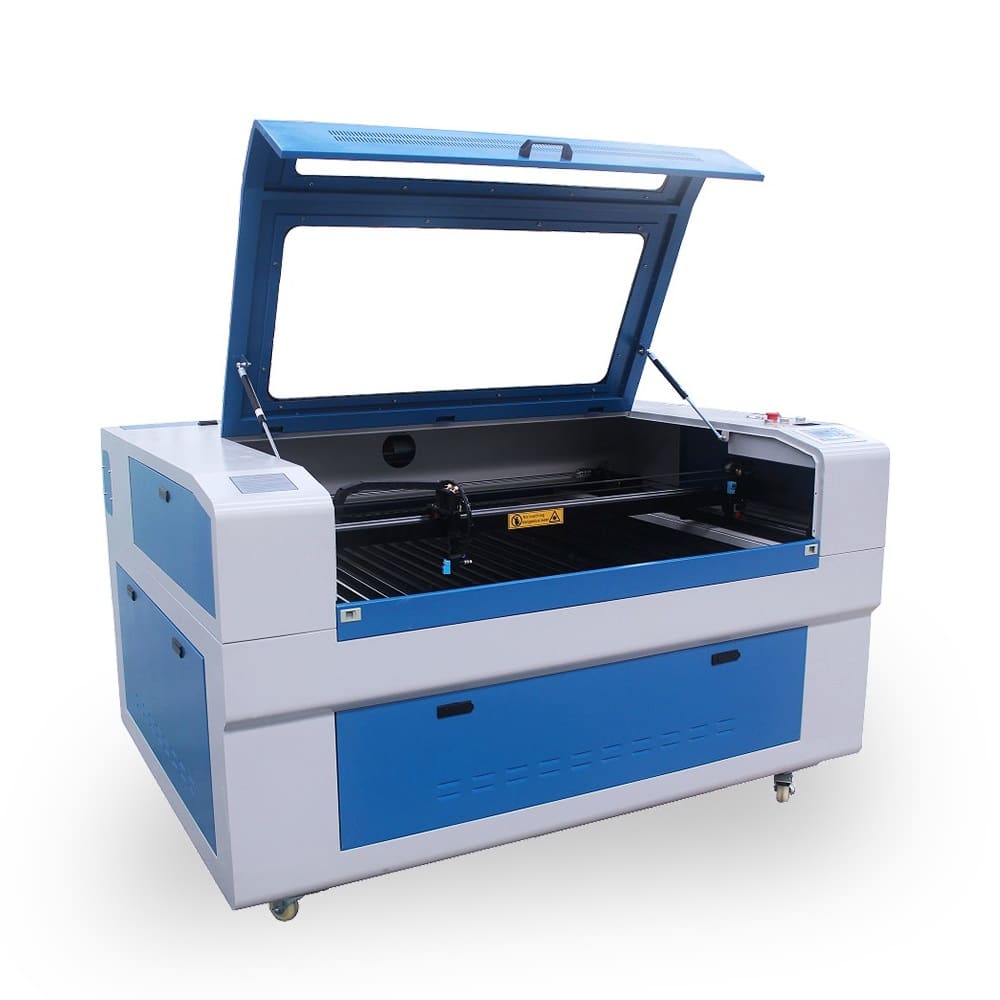

The CO2 laser wood cutter, a versatile and powerful tool, has revolutionized the woodworking industry. It utilizes a focused beam of carbon dioxide laser to precisely cut, engrave, and mark a wide range of wood materials. This article provides a comprehensive guide to CO2 laser wood cutters, covering their features, benefits, applications, and considerations for selection and operation.

Table of Content

- 1 CO2 Laser Wood Cutter: A Comprehensive Guide for Precision Cutting

- 1.1 Introduction

- 1.2 Understanding CO2 Laser Wood Cutters

- 1.3 Benefits of Using CO2 Laser Wood Cutters

- 1.4 Understanding CO2 Laser Wood Cutters

- 1.5 Applications of CO2 Laser Wood Cutters

- 1.6 Considerations for Selecting a CO2 Laser Wood Cutter

- 1.7 Operating a CO2 Laser Wood Cutter

- 1.8 Maintenance and Troubleshooting

- 1.9 Conclusion

- 1.10 FAQs

Understanding CO2 Laser Wood Cutters

CO2 laser wood cutters operate on the principle of laser ablation, where a concentrated beam of laser energy is directed onto the workpiece. The high-energy photons of the laser beam interact with the wood, causing it to vaporize or burn, resulting in precise cuts or engravings.

H2: Key Components of a CO2 Laser Wood Cutter

- Laser Tube: Generates the laser beam.

- Laser Power Supply: Provides electrical power to the laser tube.

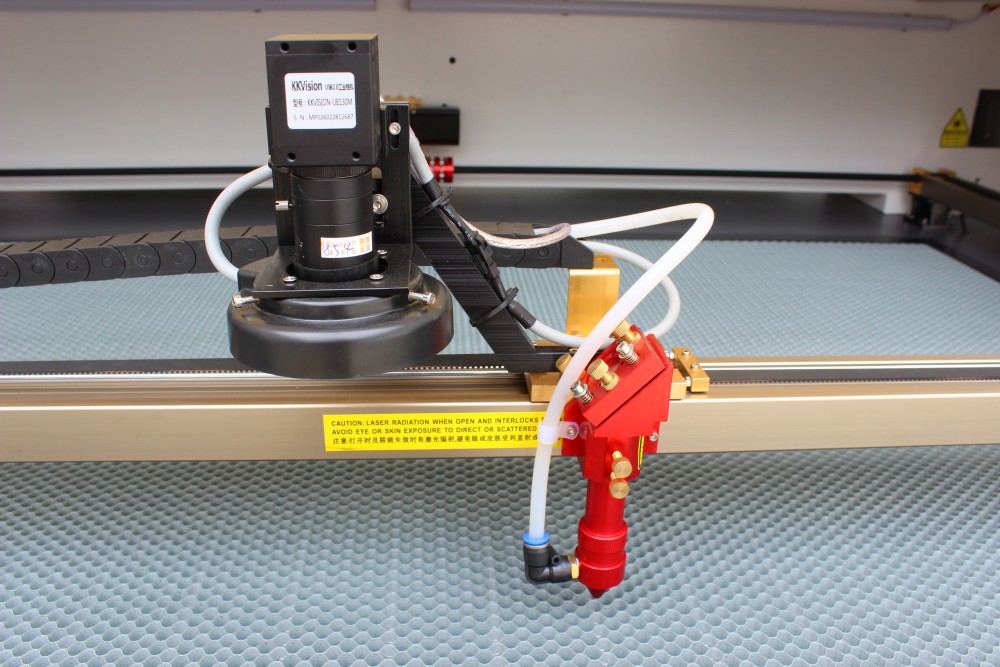

- Optics System: Focuses and directs the laser beam.

- Cutting Bed: Supports the workpiece during cutting or engraving.

- Computer Controller: Controls the laser parameters and machine movement.

DOWNLOAD SVG FILES FOR LASER CUTTING

Benefits of Using CO2 Laser Wood Cutters

The CO2 laser wood cutter, a versatile and powerful tool, has revolutionized the woodworking industry. It utilizes a focused beam of carbon dioxide laser to precisely cut, engrave, and mark a wide range of wood materials. This article provides a comprehensive guide to CO2 laser wood cutters, covering their features, benefits, applications, and considerations for selection and operation.

- Best Wood For Glowforge Best Wood For Glowforge: A Comprehensive Guide To Choosing The Perfect Material

- Cnc Wood Laser Engraver CNC Wood Laser Engraver: Revolutionizing Woodworking With Precision And Creativity

- Wood Laser Printing H1: Wood Laser Printing: A Comprehensive Guide To Engraving And Etching On Wood

- Lasercutter Wood Lasercutter Wood: A Comprehensive Guide To Materials And Applications

- Small Wood Laser Cutter For Sale Small Wood Laser Cutter For Sale: A Comprehensive Guide

Understanding CO2 Laser Wood Cutters

H2: How CO2 Laser Wood Cutters Work

DOWNLOAD SVG FILES FOR LASER CUTTING

CO2 laser wood cutters operate on the principle of laser ablation, where a concentrated beam of laser energy is directed onto the workpiece. The high-energy photons of the laser beam interact with the wood, causing it to vaporize or burn, resulting in precise cuts or engravings.

H2: Key Components of a CO2 Laser Wood Cutter

- Cutting and engraving signs, logos, and promotional materials

- Producing display stands and fixtures

- Creating scale models, architectural components, and intricate latticework

- Precision cutting for woodworking projects

- Wear appropriate safety gear (laser safety glasses, gloves, etc.).

- Ensure proper ventilation and fume extraction.

- Never leave the laser unattended during operation.

- Calibrate the laser beam to ensure accurate cutting and engraving.

- Adjust laser parameters (power, speed, etc.) based on the material being processed.

- Securely fix the workpiece to the cutting bed using clamps or a vacuum table.

- Avoid touching the workpiece with bare hands to prevent burn marks.

- Start the laser cutter and monitor the cutting or engraving process.

- Adjust laser parameters as needed to optimize the results.

- Clean the laser tube and optics system regularly to maintain optimal performance.

- Inspect the laser power supply and other components for any signs of damage or wear.

- Poor Cut Quality: Check laser calibration, laser power, or workpiece material compatibility.

- Laser Not Firing: Inspect laser tube, power supply, and control software.

- Fume Accumulation: Ensure proper ventilation and clean the fume extraction system regularly.

H2: Precision Cutting and Engraving

CO2 laser wood cutters offer unmatched precision, enabling intricate cuts and engravings with fine details and smooth edges.

H2: High Speed and Efficiency

The laser beam can cut or engrave at high speeds, resulting in increased productivity and reduced production time.

H2: Versatility

CO2 laser wood cutters can handle a wide range of wood materials, including plywood, MDF, hardwoods, and softwoods.

H2: No Contact Cutting

Unlike traditional cutting tools, the laser beam does not make physical contact with the workpiece, eliminating the risk of damage or distortion.

Applications of CO2 Laser Wood Cutters

H2: Woodworking and Crafts

H2: Signage and Displays

H2: Architectural and Model Making

Considerations for Selecting a CO2 Laser Wood Cutter

H2: Laser Power

Determines the thickness and type of wood that can be cut or engraved. Higher power lasers can handle thicker and denser materials.

H2: Cutting Area

The size of the cutting bed determines the maximum workpiece size that can be processed.

H2: Software and Controls

Intuitive software and user-friendly controls ensure ease of use and efficient operation.

H2: Safety Features

Laser cutters should be equipped with safety features such as enclosed work areas, fume extraction systems, and emergency stop buttons.

Operating a CO2 Laser Wood Cutter

H2: Safety Precautions

H2: Setting Up the Laser

H2: Loading and Securing the Workpiece

H2: Running the Laser

Maintenance and Troubleshooting

H2: Regular Maintenance

H2: Troubleshooting Common Issues

Conclusion

CO2 laser wood cutters are powerful and versatile tools that offer exceptional precision, speed, and versatility in woodworking applications. By understanding the technology, benefits, and considerations involved, users can make informed choices and operate their laser cutters safely and effectively to achieve optimal results.

FAQs

Q: What is the difference between CO2 and fiber laser wood cutters?

A: CO2 lasers are suitable for a wide range of wood materials, while fiber lasers excel at cutting metals and certain plastics.

Q: Can CO2 laser wood cutters cut non-wood materials?

A: Yes, some CO2 laser cutters can cut or engrave materials such as acrylic, leather, and fabric, depending on the laser power and material compatibility.

Q: How thick of wood can a CO2 laser cutter cut?

A: The cutting thickness depends on the laser power. Typically, CO2 laser cutters can cut wood up to 1/2 inch (12.7 mm) thick or more.