Fiber Laser Wood Cutting: A Comprehensive Guide

Introduction

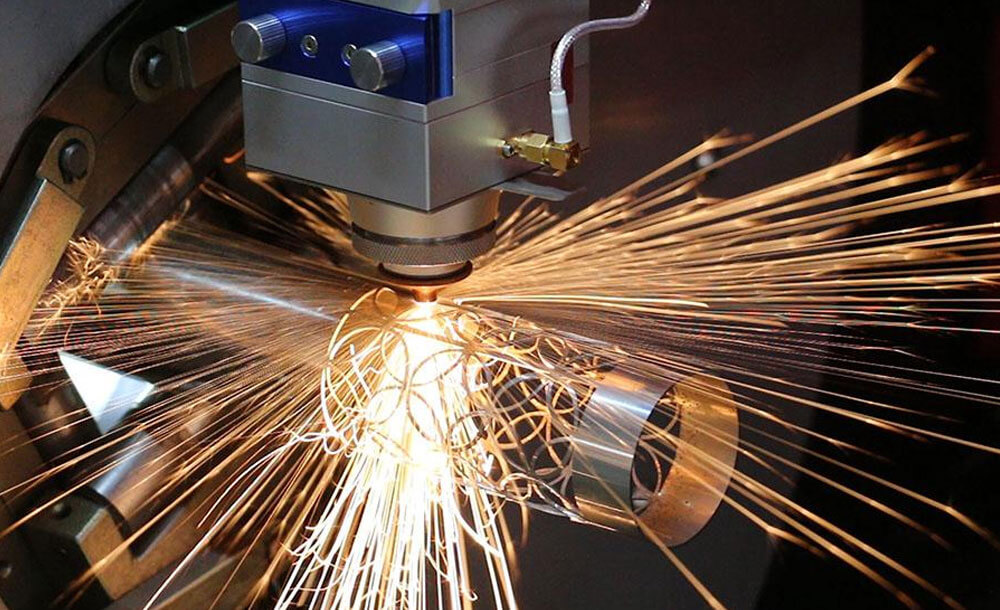

Fiber laser wood cutting has revolutionized the woodworking industry with its precision, speed, and versatility. This innovative technology utilizes a high-powered fiber laser to cut and engrave wood with unmatched accuracy and detail. In this comprehensive guide, we will delve into the world of fiber laser wood cutting, exploring its advantages, applications, and best practices.

Table of Content

H1: Advantages of Fiber Laser Wood Cutting

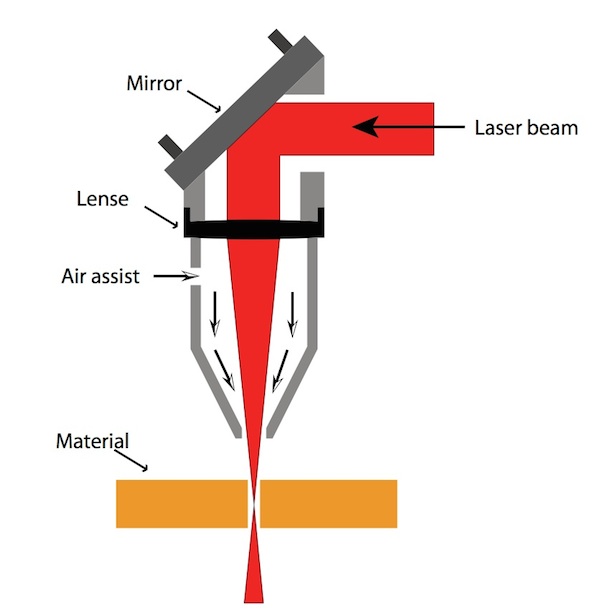

- Precision Cutting: The highly focused laser beam enables precise cuts with minimal kerf width, resulting in clean and accurate edges.

- Speed: Fiber lasers cut at lightning speeds, significantly reducing production time and increasing efficiency.

- Versatility: Fiber lasers can cut a wide range of wood species, from hardwoods to softwoods, and even plywood and MDF.

- Non-Contact Cutting: The laser beam does not physically touch the wood, eliminating the risk of tool wear or damage to the material.

- Low Maintenance: Fiber lasers require minimal maintenance, with a long lifespan and low operating costs.

H2: Applications of Fiber Laser Wood Cutting

Fiber laser wood cutting finds application in a vast array of industries, including:

- Laser Wood Cutting Near Me Laser Wood Cutting Near Me: A Comprehensive Guide

- Best Laser Wood Cutter For Small Business Best Laser Wood Cutter For Small Business: A Comprehensive Guide

- Cut Wood Shapes Cut Wood Shapes: A Comprehensive Guide To Precision Cutting Techniques

- Custom Cut Wood Shapes Custom Cut Wood Shapes: Elevate Your Projects With Precision And Creativity

- Wood Laser Engraver And Cutter Wood Laser Engraver And Cutter: A Comprehensive Guide

- Precision Cutting: The highly focused laser beam enables precise cuts with minimal kerf width, resulting in clean and accurate edges.

- Speed: Fiber lasers cut at lightning speeds, significantly reducing production time and increasing efficiency.

- Furniture Manufacturing: Precision cutting of intricate furniture components, such as chair legs and tabletops.

- Cabinets and Closets: Production of custom cabinets, closets, and other woodworking projects with precise joinery.

- Musical Instruments: Cutting and shaping of guitar bodies, violin scrolls, and other instrument components.

- Decorative Items: Creation of decorative wood panels, wall art, and personalized gifts with intricate designs.

- Industrial Applications: Laser cutting of wooden crates, pallets, and other industrial components.

- Material Selection: Choose high-quality wood with a consistent grain structure for best cutting results.

- Laser Parameters: Optimize laser power, speed, and focus settings to suit the specific wood species and thickness.

- Ventilation: Ensure proper ventilation to remove fumes and smoke generated during cutting.

- Safety Precautions: Wear appropriate protective gear, including safety glasses and a respirator, while operating the laser.

- Maintenance: Regularly clean and inspect the laser system to maintain its performance and longevity.

-

What is the maximum thickness of wood that can be cut with a fiber laser?

- The maximum cutting thickness depends on the laser power and beam quality, typically ranging from 10 mm to 25 mm for most fiber lasers.

-

Can fiber lasers cut metal?

- Yes, fiber lasers are also capable of cutting thin metal sheets, but they are primarily used for wood cutting.

-

How does fiber laser wood cutting compare to CNC routing?

- Fiber laser cutting offers superior precision and speed, while CNC routing provides versatility in cutting complex shapes and profiles.

-

What is the cost of a fiber laser wood cutting machine?

- The cost of a fiber laser wood cutting machine varies depending on its size, power, and features, ranging from tens of thousands of dollars to hundreds of thousands of dollars.

Fiber laser wood cutting has revolutionized the woodworking industry with its precision, speed, and versatility. This innovative technology utilizes a high-powered fiber laser to cut and engrave wood with unmatched accuracy and detail. In this comprehensive guide, we will delve into the world of fiber laser wood cutting, exploring its advantages, applications, and best practices.

H1: Advantages of Fiber Laser Wood Cutting

Fiber laser wood cutting offers numerous advantages over traditional methods, including:

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Best Practices for Fiber Laser Wood Cutting

To achieve optimal results with fiber laser wood cutting, it is essential to follow best practices:

H2: Conclusion

Fiber laser wood cutting has emerged as a game-changer in the woodworking industry. Its precision, speed, and versatility make it an ideal solution for a wide range of applications. By understanding the advantages, applications, and best practices of fiber laser wood cutting, businesses and hobbyists alike can unlock the full potential of this transformative technology.

FAQs