Laser Cut Out Wood: A Comprehensive Guide to Precision Cutting and Engraving

Introduction

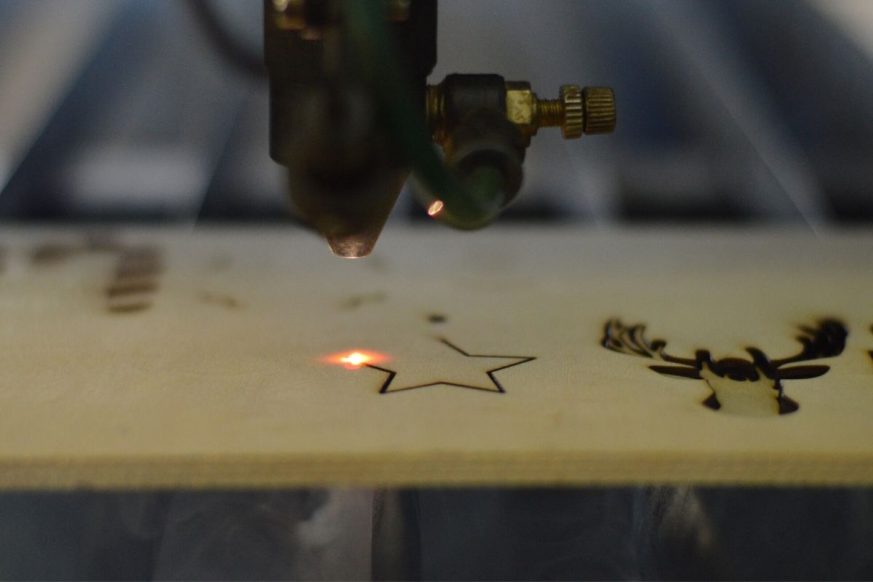

Laser cut out wood is a versatile material that offers endless possibilities for creative projects and industrial applications. By utilizing the precision and accuracy of laser technology, wood can be transformed into intricate designs, detailed engravings, and functional components. This comprehensive guide will delve into the world of laser cut out wood, exploring its benefits, applications, techniques, and best practices.

Table of Content

- 1 Laser Cut Out Wood: A Comprehensive Guide to Precision Cutting and Engraving

- 1.1 Introduction

- 1.2 Benefits of Laser Cut Out Wood

- 1.3 Applications of Laser Cut Out Wood

- 1.4 Benefits of Laser Cut Out Wood

- 1.5 Techniques for Laser Cutting Wood

- 1.6 Best Practices for Laser Cutting Wood

- 1.7 Conclusion

- 1.8 FAQs

Benefits of Laser Cut Out Wood

- Precision and Accuracy: Lasers produce highly precise cuts with minimal deviation, ensuring consistent and intricate designs.

- Intricate Detailing: Laser technology allows for the creation of intricate patterns and details that would be difficult or impossible to achieve manually.

- Speed and Efficiency: Lasers cut through wood quickly and efficiently, reducing production time and increasing productivity.

- Non-Contact Cutting: Lasers do not physically touch the wood during cutting, eliminating the risk of damage or deformation.

- Versatile Material: Laser cut out wood can be used for a wide range of applications, from decorative items to industrial components.

Applications of Laser Cut Out Wood

Laser cut out wood finds applications in various industries and creative endeavors, including:

- Laser On Wood Engraving Laser Engraving On Wood: A Comprehensive Guide To Crafting Precision Designs

- Etsy Laser Cut Wood Etsy Laser Cut Wood: A Comprehensive Guide

- 3d Laser Cut Wood 3D Laser Cut Wood: A Comprehensive Guide

- Laser Wood Carving Near Me Laser Wood Carving Near Me: An In-Depth Guide

- Wood Laser Printing H1: Wood Laser Printing: A Comprehensive Guide To Engraving And Etching On Wood

- Precision and Accuracy: Lasers produce highly precise cuts with minimal deviation, ensuring consistent and intricate designs.

- Intricate Detailing: Laser technology allows for the creation of intricate patterns and details that would be difficult or impossible to achieve manually.

- Arts and Crafts: Laser cut out wood is used to create decorative items such as wall art, jewelry, and home décor.

- Industrial: Laser cut out wood is used in industrial applications such as prototyping, manufacturing, and packaging.

- Architecture: Laser cut out wood is used in architectural models, building components, and decorative panels.

- Musical Instruments: Laser cut out wood is used to create acoustic panels, guitar bodies, and other musical instrument components.

- Signage: Laser cut out wood is used to create custom signs, logos, and displays.

- Vector Cutting: This technique uses a laser beam to follow a defined path, cutting through the wood along the specified lines.

- Raster Engraving: This technique uses a laser beam to scan the wood surface, creating patterns or images by varying the intensity and speed of the laser.

- Compound Cutting: This technique combines vector cutting and raster engraving to create complex designs that include both cutouts and engravings.

- Perforation: This technique uses a laser beam to create small holes or perforations in the wood, creating decorative effects or reducing weight.

- Choose the Right Wood: Different types of wood have varying properties that affect laser cutting results. Select wood that is suitable for the desired application and laser cutting technique.

- Prepare the Wood: Ensure that the wood is clean, dry, and free of any contaminants. Sanding or smoothing the surface can improve cutting accuracy.

- Set the Correct Laser Parameters: Determine the optimal laser power, speed, and focus settings for the specific wood type and cutting technique.

- Use Proper Ventilation: Laser cutting wood produces fumes and smoke, so adequate ventilation is crucial for safety and to prevent damage to the laser equipment.

- Clean the Laser Lens: Regular cleaning of the laser lens is essential to maintain optimal performance and prevent damage.

Laser cut out wood is a versatile material that offers endless possibilities for creative projects and industrial applications. By utilizing the precision and accuracy of laser technology, wood can be transformed into intricate designs, detailed engravings, and functional components. This comprehensive guide will delve into the world of laser cut out wood, exploring its benefits, applications, techniques, and best practices.

Benefits of Laser Cut Out Wood

Laser cutting wood provides several advantages over traditional cutting methods, including:

DOWNLOAD SVG FILES FOR LASER CUTTING

Techniques for Laser Cutting Wood

The process of laser cutting wood involves several techniques to achieve desired results:

Best Practices for Laser Cutting Wood

To ensure optimal results when laser cutting wood, it is essential to follow these best practices:

Conclusion

Laser cut out wood has revolutionized the way we work with wood, enabling the creation of intricate designs, detailed engravings, and functional components with precision and efficiency. Its versatility and wide range of applications make it an indispensable material for both creative and industrial endeavors. By understanding the benefits, techniques, and best practices of laser cutting wood, individuals and businesses can harness its full potential to bring their projects to life.

FAQs

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness of wood that can be laser cut depends on the type of laser used and the power of the laser. Generally, CO2 lasers can cut wood up to 1 inch thick, while fiber lasers can cut wood up to 0.5 inches thick.

Q: Can laser cut out wood be painted or stained?

A: Yes, laser cut out wood can be painted or stained to enhance its appearance or protect it from the elements. However, it is important to note that painting or staining may affect the laser-cut edges.

Q: How do I prevent burning or charring when laser cutting wood?

A: To prevent burning or charring, use the correct laser parameters, ensure proper ventilation, and avoid cutting through knots or other imperfections in the wood.