Laser Cut Ply Wood: A Comprehensive Guide

Introduction

Laser cut plywood is a versatile material that is used in a wide variety of applications, from furniture and home décor to industrial products and signage. It is made by cutting plywood with a laser cutter, which produces precise and intricate cuts that would be difficult or impossible to achieve with traditional methods.

Table of Content

Advantages of Laser Cut Plywood

- Precision: Laser cutters can produce extremely precise cuts, with tolerances of up to 0.001 inches. This makes laser cut plywood ideal for applications where accuracy is critical.

- Intricacy: Laser cutters can cut complex and intricate designs that would be difficult or impossible to achieve with traditional methods. This makes laser cut plywood ideal for creating unique and eye-catching products.

- Versatility: Laser cut plywood can be used for a wide variety of applications, from furniture and home décor to industrial products and signage. It is also compatible with a variety of finishes, including paint, stain, and veneer.

- Durability: Laser cut plywood is a durable material that can withstand wear and tear. It is also resistant to moisture and pests.

DOWNLOAD SVG FILES FOR LASER CUTTING

Applications of Laser Cut Plywood

Laser cut plywood is used in a wide variety of applications, including:

- Furniture: Laser cut plywood can be used to create custom furniture, such as chairs, tables, and beds. It is also used to create decorative accents, such as headboards and wall art.

- Wooden Laser Cut Wooden Laser Cut: A Comprehensive Guide

- Fiber Laser On Wood Fiber Laser On Wood: A Comprehensive Guide

- Laser Wood Cutter Engraver Laser Wood Cutter Engraver: Unleash Your Creative Potential

- Cricut Wood Etching Cricut Wood Etching: A Comprehensive Guide For Beginners And Experts

- Laser Wood Signs Laser Wood Signs: A Comprehensive Guide To Crafting Custom Masterpieces

- Precision: Laser cutters can produce extremely precise cuts, with tolerances of up to 0.001 inches. This makes laser cut plywood ideal for applications where accuracy is critical.

- Intricacy: Laser cutters can cut complex and intricate designs that would be difficult or impossible to achieve with traditional methods. This makes laser cut plywood ideal for creating unique and eye-catching products.

- Home décor: Laser cut plywood can be used to create a variety of home décor items, such as lamps, picture frames, and coasters. It is also used to create custom wall art and other decorative accents.

- Industrial products: Laser cut plywood is used in a variety of industrial products, such as packaging, displays, and signage. It is also used to create custom parts and components for a variety of machines and devices.

- Signage: Laser cut plywood is a popular material for signage, as it can be used to create custom signs with intricate designs. It is also durable and resistant to fading, making it ideal for outdoor use.

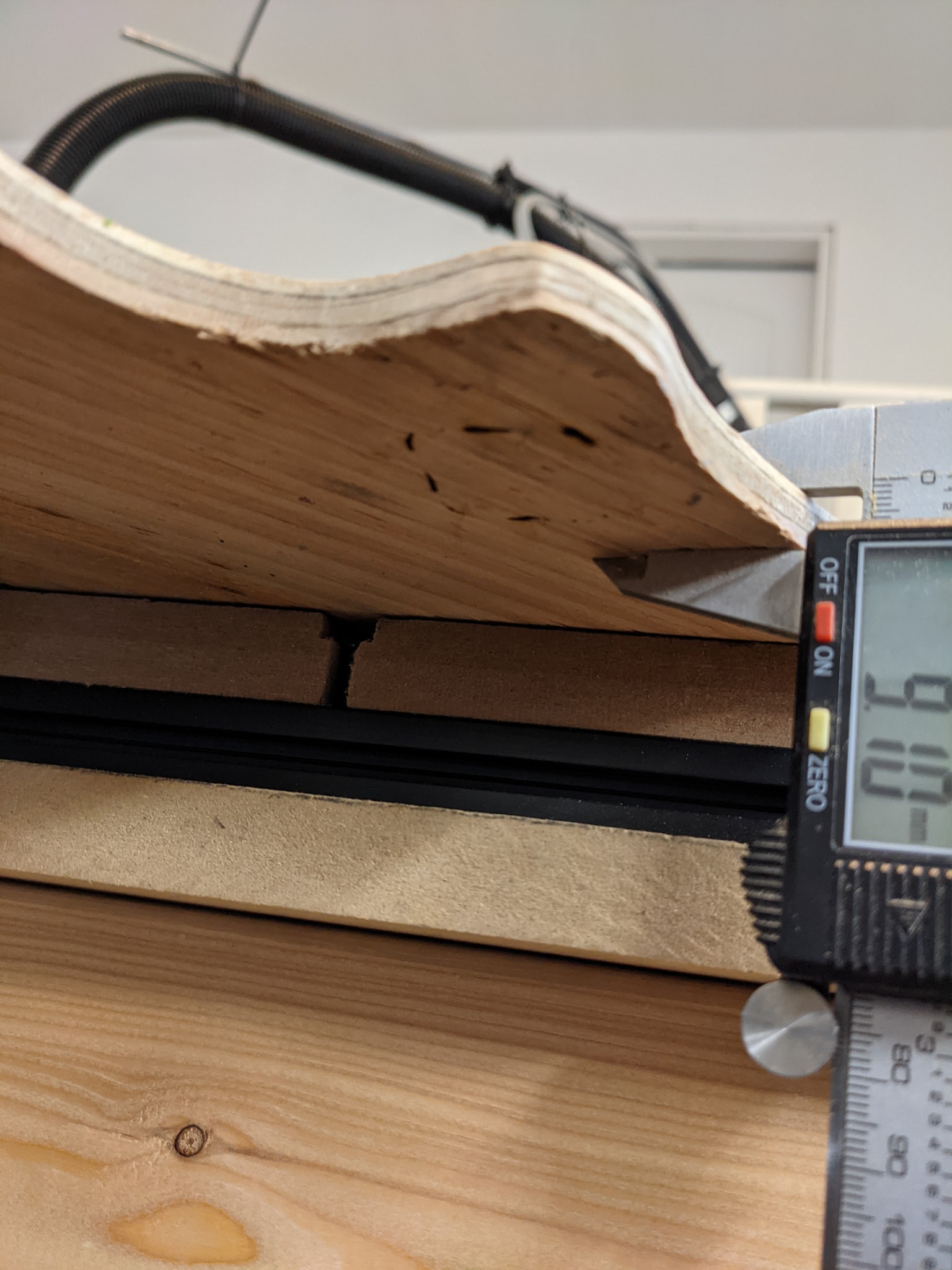

- Thickness: The thickness of the plywood will determine the type of laser cutter that is needed. Thin plywood can be cut with a CO2 laser, while thicker plywood requires a fiber laser.

- Type of plywood: The type of plywood will also affect the laser cutting process. Hardwood plywood is more difficult to cut than softwood plywood.

- Design: The design of the product will also affect the laser cutting process. Complex designs will require a laser cutter with high precision.

- Finish: The finish of the product will also affect the laser cutting process. Some finishes, such as paint, can interfere with the laser cutting process.

Laser cut plywood is a versatile material that is used in a wide variety of applications, from furniture and home décor to industrial products and signage. It is made by cutting plywood with a laser cutter, which produces precise and intricate cuts that would be difficult or impossible to achieve with traditional methods.

Advantages of Laser Cut Plywood

Laser cut plywood offers several advantages over other materials, including:

DOWNLOAD SVG FILES FOR LASER CUTTING

How Laser Cut Plywood is Made

Laser cut plywood is made by cutting plywood with a laser cutter. Laser cutters use a high-powered laser to cut through the plywood, producing precise and intricate cuts. The process is typically automated, with the laser cutter following a computer-generated design.

The type of laser used in laser cutting plywood depends on the thickness and type of plywood being cut. CO2 lasers are commonly used for cutting thin plywood, while fiber lasers are used for cutting thicker plywood.

Factors to Consider When Choosing Laser Cut Plywood

When choosing laser cut plywood, there are several factors to consider, including:

Conclusion

Laser cut plywood is a versatile material that is used in a wide variety of applications. It offers several advantages over other materials, including precision, intricacy, versatility, and durability. When choosing laser cut plywood, there are several factors to consider, including thickness, type of plywood, design, and finish.

FAQs

Q: What is the difference between laser cut plywood and CNC cut plywood?

A: Laser cut plywood is cut with a laser cutter, while CNC cut plywood is cut with a CNC router. Laser cutters use a high-powered laser to cut through the plywood, while CNC routers use a rotating bit to cut through the plywood. Laser cut plywood is typically more precise and intricate than CNC cut plywood.

Q: Can laser cut plywood be painted or stained?

A: Yes, laser cut plywood can be painted or stained. However, it is important to note that some finishes, such as paint, can interfere with the laser cutting process. It is best to test the finish on a small piece of plywood before applying it to the entire product.

Q: Is laser cut plywood durable?

A: Yes, laser cut plywood is a durable material that can withstand wear and tear. It is also resistant to moisture and pests.