Laser Cutouts Wood: A Comprehensive Guide to Precision Cutting and Customization

Laser cutouts wood is a versatile material that offers endless possibilities for creating intricate and precise designs. With its ability to cut through wood with precision, lasers have revolutionized the woodworking industry, enabling the creation of unique and personalized items.

H2: Benefits of Laser Cutouts Wood

Table of Content

- 1 Laser Cutouts Wood: A Comprehensive Guide to Precision Cutting and Customization

- 1.1 H2: Benefits of Laser Cutouts Wood

- 1.2 H2: Applications of Laser Cutouts Wood

- 1.3 H2: Benefits of Laser Cutouts Wood

- 1.4 H2: Choosing the Right Laser for Wood Cutting

- 1.5 H2: Tips for Laser Cutting Wood

- 1.6 H2: Conclusion

- 1.7 H3: Frequently Asked Questions (FAQs)

Laser cutouts wood offers several advantages over traditional woodworking methods:

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Applications of Laser Cutouts Wood

Laser cutouts wood has a wide range of applications, including:

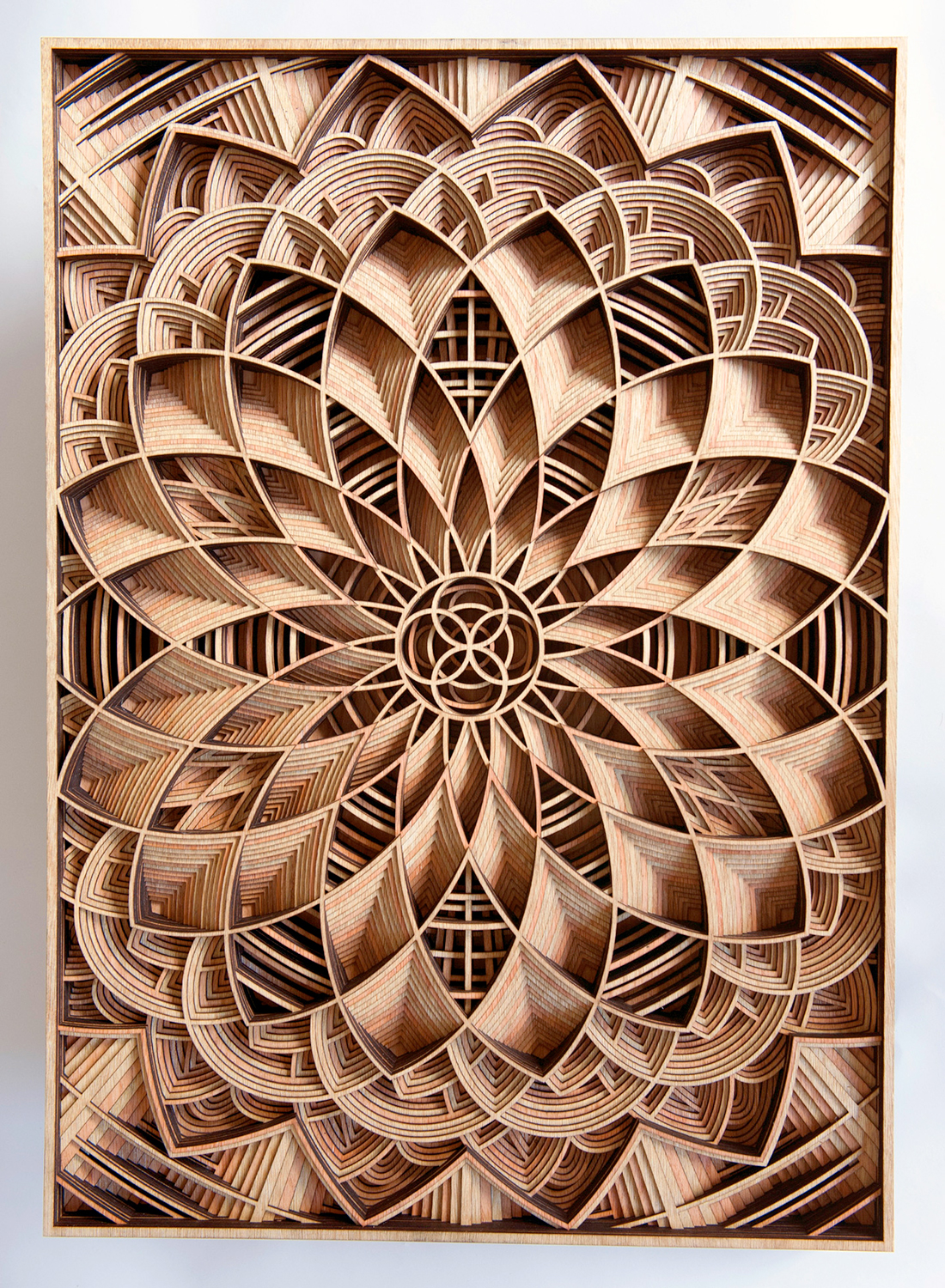

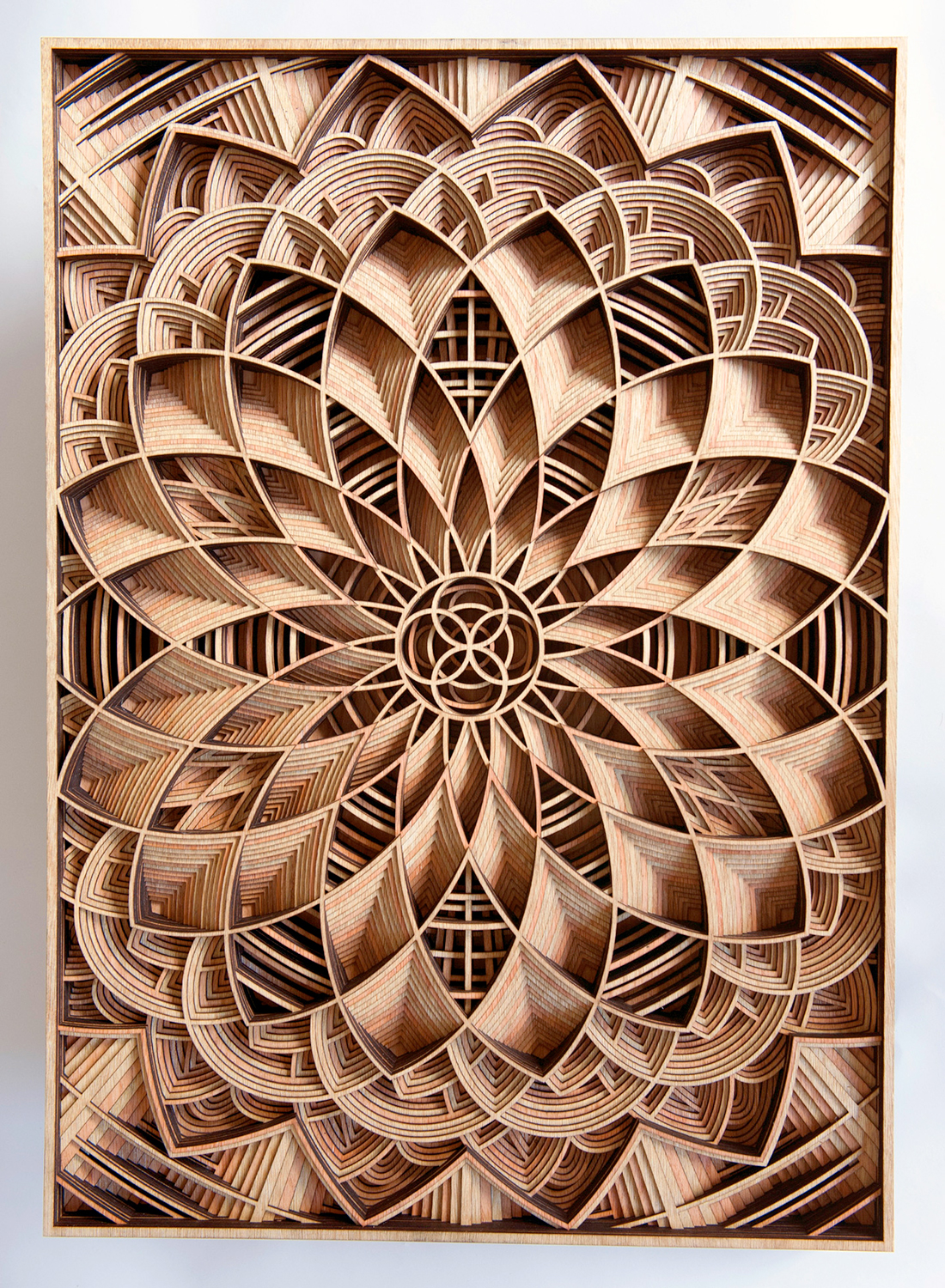

- Decorative Arts: Laser-cut wood can be used to create decorative items such as wall art, sculptures, and home décor.

- Laser Cut Wood Suppliers Laser Cut Wood Suppliers: A Comprehensive Guide

- Laser Cut Wood Pieces Laser Cut Wood Pieces: Transforming Wood Into Intricate Masterpieces

- Laser Cut Wood Wreath Laser Cut Wood Wreath: A Guide To Creating A Stunning Statement Piece

- Laser Cut Wood Design Laser Cut Wood Design: Transforming Woodworking With Precision And Innovation

- Laser Cutter For Acrylic And Wood Laser Cutter For Acrylic And Wood: A Comprehensive Guide

- Precision: Lasers cut with extreme accuracy, ensuring sharp edges and intricate details.

- Customization: Laser cutting allows for the creation of custom designs, making it ideal for personalized products and prototypes.

- Speed: Laser cutting is a fast process, significantly reducing production time compared to manual methods.

- Personalized Gifts: Custom laser-cut wood products make thoughtful and unique gifts for any occasion.

- Toys and Games: Laser-cut wood can be used to create educational toys, puzzles, and board games.

- Architectural Elements: Laser-cut wood can be used to create architectural elements such as moldings, panels, and screens.

- Industrial Applications: Laser-cut wood is used in various industrial applications, including packaging, displays, and prototyping.

- Power: The power of the laser determines the thickness of wood that can be cut.

- Wavelength: The wavelength of the laser affects the precision and cut quality.

- Beam Quality: The beam quality determines the accuracy and sharpness of the cut.

- Cutting Speed: The cutting speed determines the production efficiency.

- Software: The software used to control the laser should be user-friendly and allow for precise design input.

- Use high-quality wood: The quality of the wood used will directly affect the cut quality.

- Properly secure the wood: Secure the wood firmly in place to prevent movement during cutting.

- Set appropriate laser settings: Adjust the laser power, speed, and focus to suit the wood type and thickness.

- Use proper ventilation: Laser cutting wood releases fumes, so ensure adequate ventilation in the work area.

- Clean the laser regularly: Regular cleaning of the laser lens and mirrors will maintain optimal performance.

H2: Benefits of Laser Cutouts Wood

Laser cutouts wood offers several advantages over traditional woodworking methods:

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Choosing the Right Laser for Wood Cutting

When choosing a laser for wood cutting, consider the following factors:

H2: Tips for Laser Cutting Wood

To achieve optimal results when laser cutting wood, follow these tips:

H2: Conclusion

Laser cutouts wood offers a combination of precision, customization, and efficiency, making it an ideal material for a wide range of applications. By choosing the right laser and following the recommended tips, you can create stunning and unique laser-cut wood products.

H3: Frequently Asked Questions (FAQs)

Q: Can any type of wood be laser cut?

A: Most types of wood can be laser cut, including hardwood, softwood, and plywood. However, some woods may require different laser settings to achieve optimal results.

Q: What is the maximum thickness of wood that can be laser cut?

A: The maximum thickness of wood that can be laser cut depends on the power of the laser. Typically, lasers can cut through wood up to 1 inch thick.

Q: Can lasers cut through painted or stained wood?

A: Yes, lasers can cut through painted or stained wood, but the laser settings may need to be adjusted to account for the additional material.

Q: Is laser cutting wood safe?

A: Laser cutting wood is generally safe if proper safety precautions are followed. These include using proper ventilation, wearing protective gear, and operating the laser in a controlled environment.

Q: How can I design my own laser cutouts wood products?

A: You can design your own laser cutouts wood products using a variety of software programs, such as Adobe Illustrator or CorelDRAW. These programs allow you to create precise designs that can be exported to the laser cutting machine.