Laser Wood Carving: A Comprehensive Guide to Precision and Versatility

Introduction

Laser wood carving has emerged as a revolutionary technique in the realm of woodworking and crafts, transforming the way intricate designs and personalized creations are brought to life. This technology harnesses the power of lasers to engrave, cut, and etch wood with unparalleled precision and versatility, opening up a world of possibilities for artists, makers, and hobbyists alike.

Table of Content

- 1 Laser Wood Carving: A Comprehensive Guide to Precision and Versatility

- 1.1 Introduction

- 1.2 H1: Understanding Laser Wood Carving

- 1.3 H2: Types of Laser Systems for Wood Carving

- 1.4 H1: Understanding Laser Wood Carving

- 1.5 H2: The Basics of Laser Wood Carving

- 1.6 H3: Choosing the Right Laser System

- 1.7 H1: Laser Wood Carving Techniques

- 1.8 H2: Engraving

- 1.9 H3: Cutting

- 1.10 H3: Raster Engraving vs. Vector Cutting

- 1.11 H1: Applications of Laser Wood Carving

- 1.12 H2: Artistic Creations

- 1.13 H2: Signage and Display

- 1.14 H2: Home Decor and Accessories

- 1.15 H2: Industrial Applications

- 1.16 H1: Conclusion

- 1.17 FAQs

H1: Understanding Laser Wood Carving

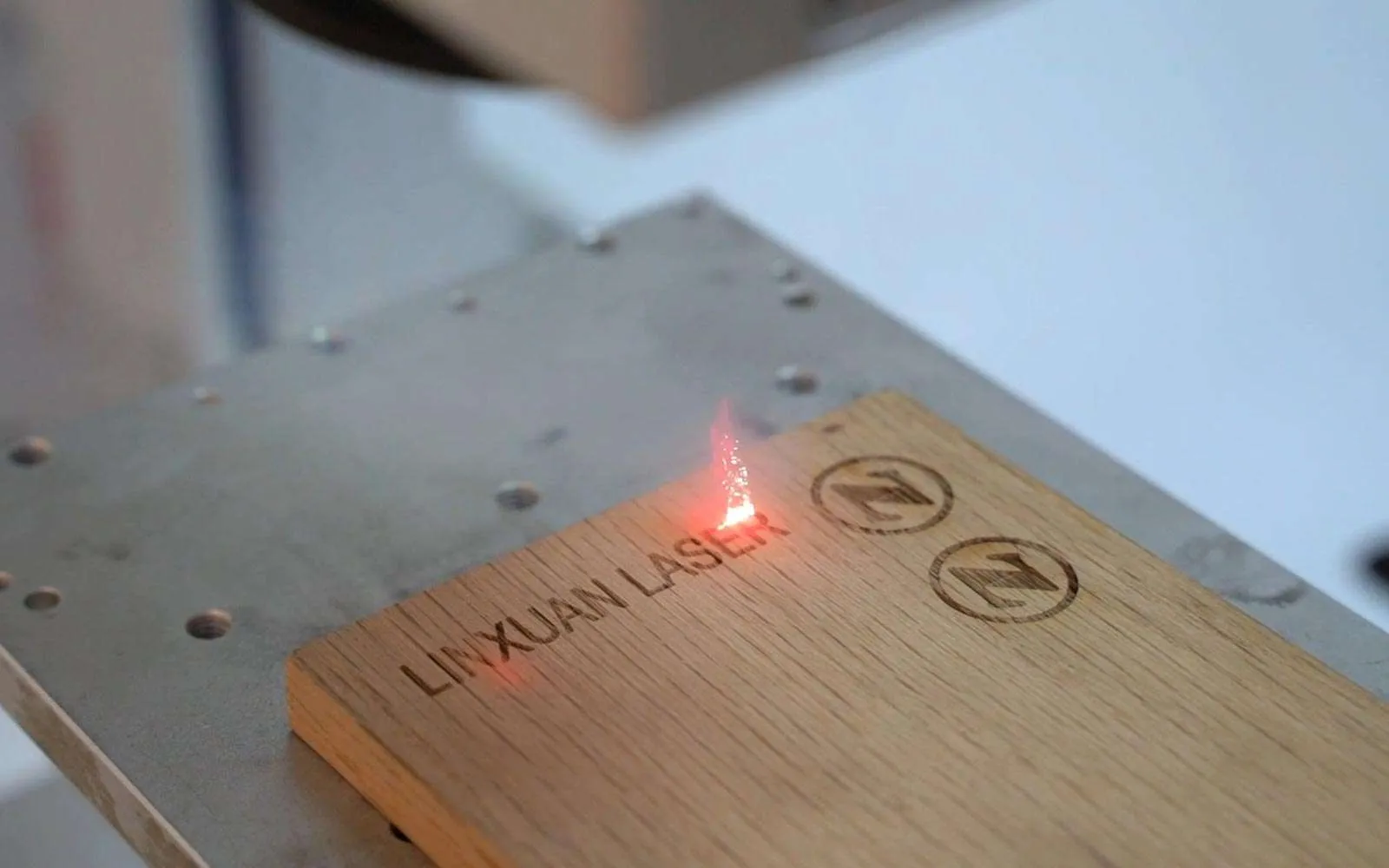

Laser wood carving involves directing a concentrated beam of laser light onto a wooden surface. The laser’s energy interacts with the wood, vaporizing or cutting it to create the desired design. This process offers several advantages over traditional carving methods:

- Precision: Lasers enable extremely precise cuts and engravings, allowing for intricate details and complex patterns.

- Speed: Laser systems operate at high speeds, making it possible to carve large or complex designs efficiently.

- Non-Contact: Laser carving does not require physical contact with the wood, eliminating the risk of damage to delicate surfaces.

- Versatility: Lasers can work with various types of wood, including hardwoods, softwoods, and plywood, offering endless creative possibilities.

H2: Types of Laser Systems for Wood Carving

There are two primary types of laser systems used for wood carving:

- Fiber Laser Wood Fiber Laser Wood: A Comprehensive Guide

- Laser Cutouts Wood Laser Cutouts Wood: A Comprehensive Guide To Precision Cutting And Customization

- Laser Cut Folding Wood Laser Cut Folding Wood: A Comprehensive Guide

- Co2 Laser Wood Engraving CO2 Laser Wood Engraving: A Comprehensive Guide To Precision And Creativity

- Custom Laser Cut Wood Shapes Custom Laser Cut Wood Shapes: Elevate Your Projects With Precision And Creativity

- Precision: Lasers enable extremely precise cuts and engravings, allowing for intricate details and complex patterns.

- CO2 Lasers: These lasers produce a beam of infrared light that is well-suited for engraving and cutting wood. They are known for their power and speed.

- Fiber Lasers: Fiber lasers emit a high-energy beam of light that is ideal for fine and detailed engraving. They offer high precision and a wide range of marking options.

- Power: Higher power lasers can cut thicker wood and engrave deeper designs.

- Speed: Laser speed determines the efficiency of the carving process.

- Precision: Fiber lasers offer the highest precision for detailed engraving.

- Budget: Laser systems vary in cost, so it’s important to consider your budget and project requirements.

- Raster Engraving: This method involves scanning the laser beam over the surface, creating a bitmap image. It is suitable for engraving photographs or images with varying shades.

- Vector Cutting: This method follows a precise path defined by vector graphics. It is used for cutting precise shapes and patterns.

- Prototyping: Creating precise wooden prototypes for product development.

- Manufacturing: Producing custom wooden components and parts.

- Packaging: Designing and cutting custom wooden boxes and packaging solutions.

Laser wood carving has emerged as a revolutionary technique in the realm of woodworking and crafts, transforming the way intricate designs and personalized creations are brought to life. This technology harnesses the power of lasers to engrave, cut, and etch wood with unparalleled precision and versatility, opening up a world of possibilities for artists, makers, and hobbyists alike.

H1: Understanding Laser Wood Carving

H2: The Basics of Laser Wood Carving

DOWNLOAD SVG FILES FOR LASER CUTTING

Laser wood carving involves directing a concentrated beam of laser light onto a wooden surface. The laser’s energy interacts with the wood, vaporizing or cutting it to create the desired design. This process offers several advantages over traditional carving methods:

H3: Choosing the Right Laser System

Selecting the appropriate laser system depends on the specific application and desired results. Consider the following factors:

H1: Laser Wood Carving Techniques

H2: Engraving

Laser engraving involves etching designs or text into the surface of the wood without cutting through it. It is commonly used for personalization, branding, or creating decorative patterns.

H3: Cutting

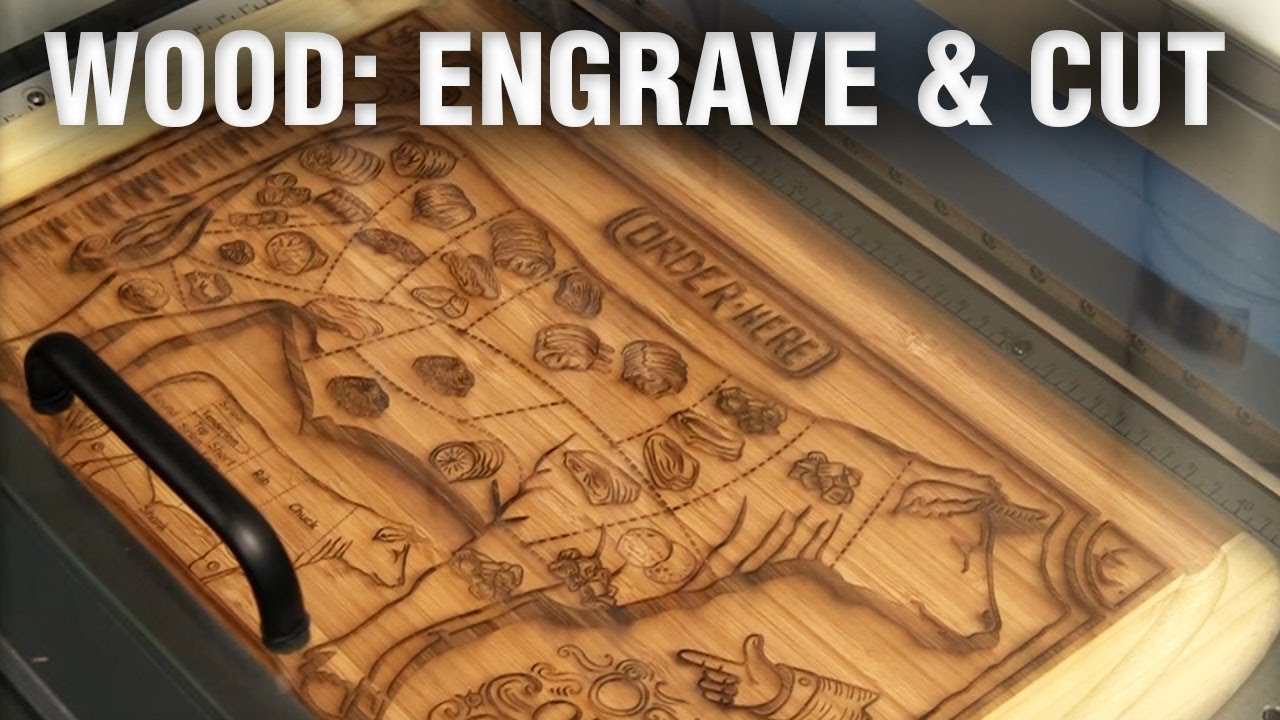

Laser cutting involves directing the laser beam through the wood, creating precise and intricate cutouts. This technique is ideal for making custom shapes, components, and intricate designs.

H3: Raster Engraving vs. Vector Cutting

H1: Applications of Laser Wood Carving

H2: Artistic Creations

Laser wood carving has become a popular medium for artists and makers to create unique and personalized works of art. It allows for intricate designs, 3D carvings, and even the production of small-scale sculptures.

H2: Signage and Display

Laser-carved wood signs and displays offer a sophisticated and durable solution for businesses, organizations, and individuals. They can be customized with logos, branding, or decorative elements.

H2: Home Decor and Accessories

Laser wood carving opens up a world of possibilities for home decor and accessories. It can be used to create custom coasters, furniture embellishments, picture frames, and more.

H2: Industrial Applications

Laser wood carving has found applications in various industries, including:

H1: Conclusion

Laser wood carving has revolutionized the art of woodworking and opened up a world of creative possibilities. Its precision, versatility, and efficiency make it an ideal tool for artists, makers, and industries alike. With the right laser system and techniques, you can create intricate designs, personalized creations, and functional objects that will leave a lasting impression.

FAQs

Q: What types of wood can be laser carved?

A: Lasers can work with various types of wood, including hardwoods, softwoods, and plywood.

Q: Is laser wood carving safe?

A: Yes, laser wood carving is generally safe when operated properly. However, it is important to follow safety precautions such as wearing protective eyewear and using a well-ventilated area.

Q: How long does it take to laser carve wood?

A: The time it takes depends on the size, complexity, and depth of the design. Small and simple designs can be completed in a few minutes, while larger and more intricate designs may take several hours.

Q: Can I laser carve wood at home?

A: Yes, it is possible to laser carve wood at home using a small desktop laser system. However, it is important to consider safety precautions and ensure proper ventilation.