Laser Wood Panels: A Comprehensive Guide to Cutting-Edge Woodworking Technology

Introduction

Laser wood panels, a revolutionary advancement in woodworking, have transformed the industry with their unparalleled precision and versatility. These panels are engineered to be compatible with laser cutting machines, enabling intricate designs, precise cuts, and customizable creations. This article delves into the world of laser wood panels, exploring their benefits, applications, and the latest advancements in this cutting-edge technology.

Table of Content

H1: Benefits of Laser Wood Panels

1. High Precision and Accuracy:

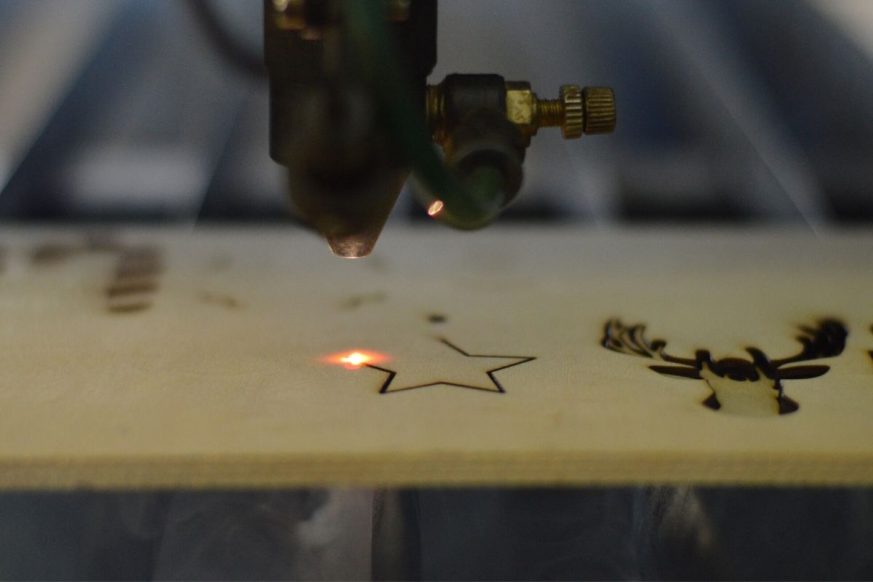

Laser cutters utilize a focused beam of light to etch or cut through materials with exceptional precision. This results in clean, crisp lines and precise shapes, ensuring intricate designs and seamless joints.

2. Versatility:

Laser wood panels can be used to create a wide range of projects, from intricate jewelry and home décor to architectural models and industrial applications. Their versatility makes them suitable for a vast array of industries and applications.

3. Speed and Efficiency:

Laser cutting machines operate at high speeds, significantly reducing production time compared to traditional woodworking methods. This efficiency allows for rapid prototyping, mass production, and quick turnaround times.

DOWNLOAD SVG FILES FOR LASER CUTTING

4. Cost-Effectiveness:

Despite the advanced technology involved, laser wood panels are cost-effective compared to traditional woodworking methods. The automated process minimizes labor costs and material waste, resulting in overall cost savings.

H2: Applications of Laser Wood Panels

Laser wood panels find applications in numerous industries and sectors, including:

Laser wood panels, a revolutionary advancement in woodworking, have transformed the industry with their unparalleled precision and versatility. These panels are engineered to be compatible with laser cutting machines, enabling intricate designs, precise cuts, and customizable creations. This article delves into the world of laser wood panels, exploring their benefits, applications, and the latest advancements in this cutting-edge technology.

- Cheap Laser Wood Cutter Cheap Laser Wood Cutter: A Comprehensive Guide

- Cut Wood Shapes Cut Wood Shapes: A Comprehensive Guide To Precision Cutting Techniques

- 3d Wood Laser Cutter 3D Wood Laser Cutter: Revolutionizing Woodworking With Precision And Efficiency

- Wood Laser Cut Wood Laser Cut: A Comprehensive Guide To Precision Crafting

- Laser Cut Timber Signs Laser Cut Timber Signs: A Comprehensive Guide

H1: Benefits of Laser Wood Panels

Laser wood panels offer a myriad of advantages that have made them a favorite among woodworkers and hobbyists alike:

DOWNLOAD SVG FILES FOR LASER CUTTING

1. High Precision and Accuracy:

Laser cutters utilize a focused beam of light to etch or cut through materials with exceptional precision. This results in clean, crisp lines and precise shapes, ensuring intricate designs and seamless joints.

2. Versatility:

1. Home Décor:

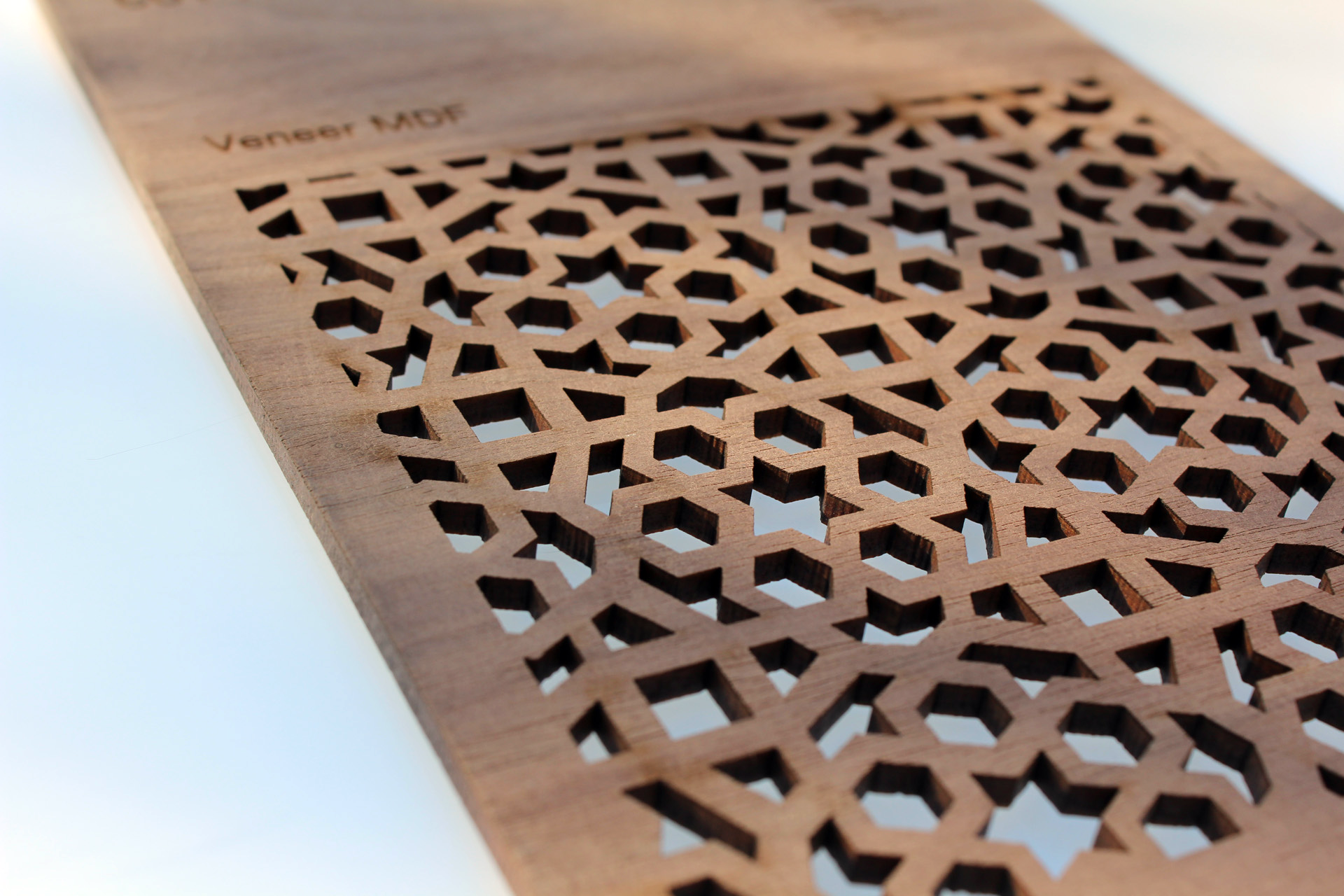

Laser-cut wood panels are widely used in creating decorative items such as wall art, furniture, and home accessories. Their intricate designs and customizable nature add a touch of elegance and sophistication to any space.

2. Jewelry and Accessories:

Laser cutters are employed to craft delicate jewelry pieces, earrings, necklaces, and fashion accessories. The precision cutting capabilities allow for intricate designs and precise shapes, resulting in unique and eye-catching creations.

3. Architectural Models:

Laser wood panels are essential for creating architectural models and prototypes. Their accuracy and detail enable the precise representation of buildings, landscapes, and interior designs.

4. Industrial Applications:

Laser-cut wood panels are utilized in various industrial applications, such as packaging, prototyping, and manufacturing. Their durability and customizable nature make them suitable for a range of industrial needs.

H3: Advanced Laser Wood Panel Technology

Recent advancements in laser wood panel technology have further enhanced their capabilities and applications:

1. 3D Laser Cutting:

3D laser cutting machines can create three-dimensional structures and objects from laser wood panels. This opens up new possibilities for architectural models, prototypes, and complex designs.

2. Engraving and Etching:

Laser wood panels can be engraved or etched with intricate designs, logos, and patterns. This technique is widely used for personalization, branding, and decorative purposes.

3. Laser Marking:

Laser markers are used to create permanent markings on laser wood panels for identification, tracking, and traceability purposes. This technology is essential in industrial applications and product manufacturing.

Conclusion

Laser wood panels have revolutionized woodworking with their exceptional precision, versatility, and efficiency. They have enabled the creation of intricate designs, precise cuts, and customizable projects in a wide range of industries and applications. As laser technology continues to advance, the possibilities with laser wood panels are boundless, promising even more innovative and creative possibilities in the future.

FAQs

1. What types of wood are suitable for laser cutting?

A variety of woods can be used for laser cutting, including hardwoods like oak and maple, and softwoods like pine and basswood. The choice depends on the desired application and aesthetic preferences.

2. What are the maintenance requirements for laser wood panels?

Regular cleaning and occasional lubrication are essential to maintain the optimal performance of laser wood panels and the laser cutting machine.

3. How to ensure safety when working with laser wood panels?

Always wear appropriate safety gear, including safety glasses, gloves, and a respirator when operating laser cutting machines. Ensure adequate ventilation and follow all manufacturer guidelines.