Multi-Layered Laser Cut Wood: A Comprehensive Guide

Introduction

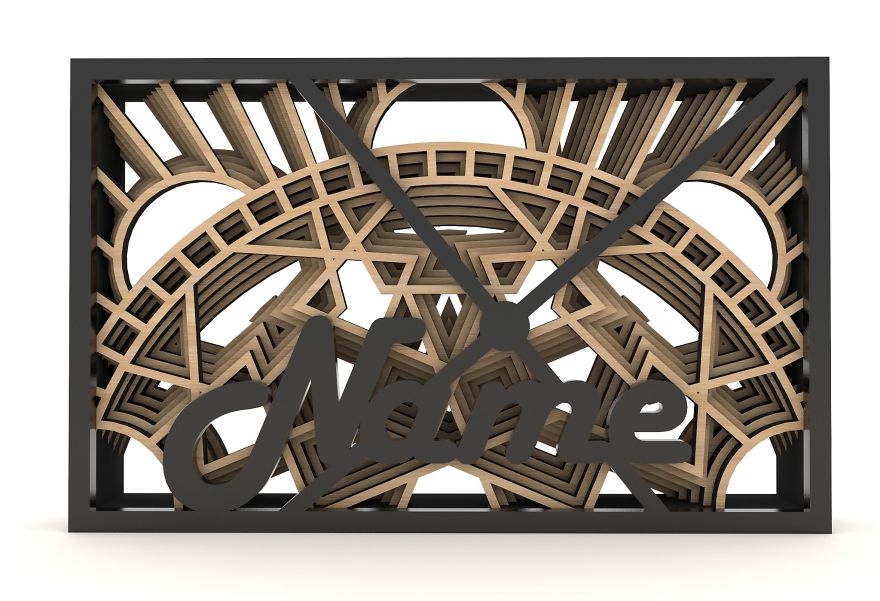

Multi-layered laser cut wood is a versatile and visually stunning material that has gained popularity in various applications, from art and décor to furniture and architectural elements. This article provides a comprehensive guide to multi-layered laser cut wood, covering its benefits, techniques, and design considerations.

Table of Content

- 1 Multi-Layered Laser Cut Wood: A Comprehensive Guide

- 1.1 Introduction

- 1.2 Benefits of Multi-Layered Laser Cut Wood

- 1.3 Techniques for Creating Multi-Layered Laser Cut Wood

- 1.4 Benefits of Multi-Layered Laser Cut Wood

- 1.5 Design Considerations for Multi-Layered Laser Cut Wood

- 1.6 Applications of Multi-Layered Laser Cut Wood

- 1.7 Conclusion

- 1.8 FAQs

Benefits of Multi-Layered Laser Cut Wood

Techniques for Creating Multi-Layered Laser Cut Wood

DOWNLOAD SVG FILES FOR LASER CUTTING

1. Design: Using a computer-aided design (CAD) software, create the desired design, taking into account the thickness and number of wood layers.

2. Material Selection: Choose the appropriate type of wood based on the desired aesthetic, strength, and budget. Common choices include plywood, MDF, and hardwoods.

3. Laser Cutting: Utilize a laser cutter to precisely cut the design into each layer of wood. Ensure proper settings for laser power, speed, and focus to achieve clean and accurate cuts.

4. Assembly: Glue or join the individual layers together to create the multi-layered structure. Use clamps or weights to ensure a strong bond.

Multi-layered laser cut wood is a versatile and visually stunning material that has gained popularity in various applications, from art and décor to furniture and architectural elements. This article provides a comprehensive guide to multi-layered laser cut wood, covering its benefits, techniques, and design considerations.

- Custom Laser Cut Wood Custom Laser Cut Wood: A Comprehensive Guide To Precision And Creativity

- Laser Cut Wood Shapes Laser Cut Wood Shapes: Unleashing Creativity And Precision

- Best Laser Wood Engraver Best Laser Wood Engraver: A Comprehensive Guide For Precision And Creativity

- Laser Wood Cut Out Laser Wood Cut Out: A Comprehensive Guide To Precision Cutting And Artistic Expression

- Laser Cutter For Balsa Wood Laser Cutter For Balsa Wood: A Comprehensive Guide

Benefits of Multi-Layered Laser Cut Wood

- Aesthetic Appeal: Multi-layered wood creates a unique and visually striking effect, adding depth and dimension to any project.

- Customization: The ability to cut intricate designs with precision allows for highly customized and personalized projects.

- Structural Strength: By layering multiple pieces of wood, the material gains increased strength and durability.

- Depth and Dimension: Determine the number of layers to create the desired depth and dimension. Experiment with different thicknesses and spacing between layers.

- Color and Texture: Consider the color and texture of the wood species used to create visual interest and contrast.

- Light Diffusion: Use laser cut patterns to allow light to pass through the wood, creating beautiful effects when used in lighting fixtures.

- Structural Integrity: Ensure that the design is structurally sound by considering the weight and load-bearing capacity of the wood.

- Tables and chairs

- Cabinets and shelves

- Headboards and accent pieces

-

Lamps and chandeliers

-

Pendant lights and sconces

-

Architectural Elements

-

Wall panels and ceiling tiles

-

Decorative moldings and trim

-

Custom architectural features

DOWNLOAD SVG FILES FOR LASER CUTTING

Design Considerations for Multi-Layered Laser Cut Wood

Applications of Multi-Layered Laser Cut Wood

Art and Décor:

Furniture:

Lighting:

Conclusion

Multi-layered laser cut wood is an innovative and versatile material that offers endless possibilities for design and application. By understanding the techniques and design considerations involved, you can create stunning and functional projects that add depth, dimension, and visual appeal to any space.

FAQs

Q: What is the best type of wood for multi-layered laser cutting?

A: The choice of wood depends on the desired aesthetic and strength. Plywood, MDF, and hardwoods are common options.

Q: Can I cut different materials with a laser cutter?

A: Yes, laser cutters can cut a variety of materials, including acrylic, fabric, leather, and metal.

Q: How can I ensure a strong bond between layers?

A: Use a high-quality wood glue and apply clamps or weights to maintain pressure during the drying process.

Q: Can I paint or stain multi-layered laser cut wood?

A: Yes, you can paint or stain the wood to achieve the desired finish. However, it’s recommended to seal the wood first to protect it from moisture and wear.