Wood to Laser Cut: A Comprehensive Guide

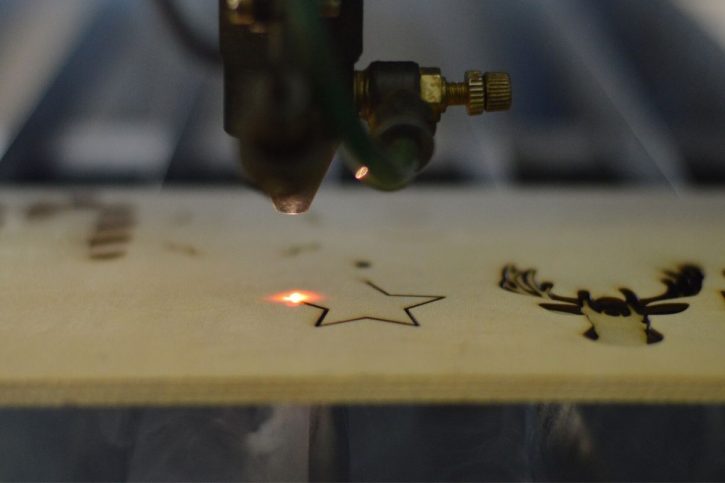

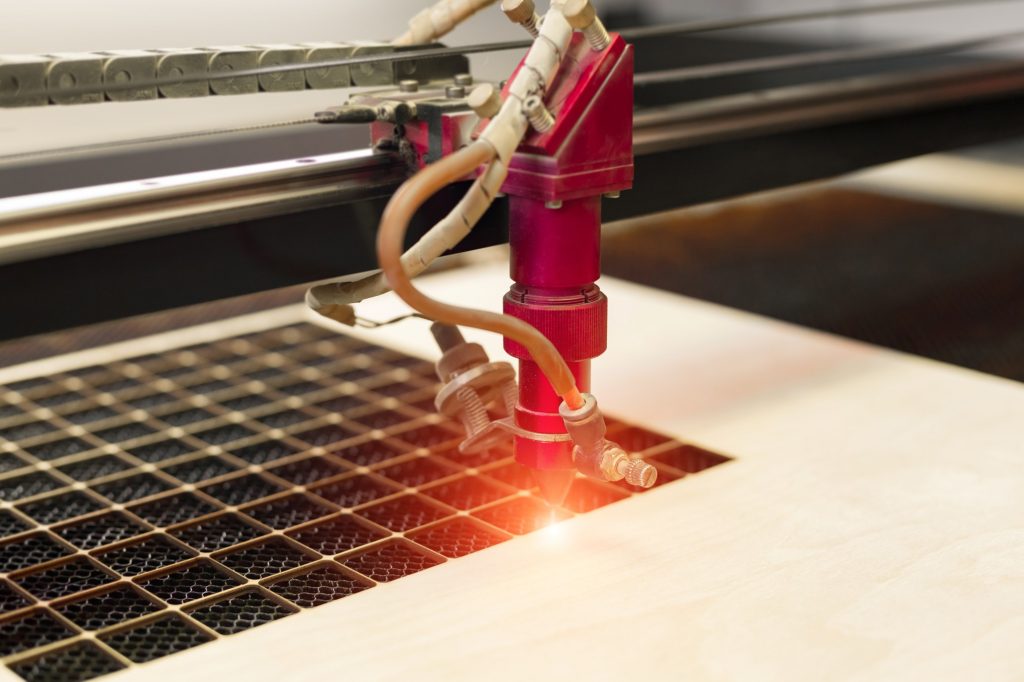

Laser cutting has revolutionized the woodworking industry, enabling intricate designs, precision cuts, and mass production. This article delves into the various types of wood suitable for laser cutting, their advantages and disadvantages, and tips for optimizing the process.

Types of Wood for Laser Cutting

Table of Content

1. Hardwoods

2. Softwoods

- Pine: Lightweight, affordable, and easy to cut. Suitable for simple designs and decorative applications.

- Fir: Similar to pine, but slightly harder and more durable. Produces clean, precise cuts.

- Cedar: Naturally rot-resistant and weather-resistant. Ideal for outdoor projects.

DOWNLOAD SVG FILES FOR LASER CUTTING

Types of Wood for Laser Cutting

- Modern Laser Cut Wood Panels Modern Laser Cut Wood Panels: Revolutionizing Interior Design And Architecture

- Desktop Wood Laser Cutter Desktop Wood Laser Cutter: An In-Depth Guide

- Laser Wood Cut Outs Laser Wood Cut Outs: A Comprehensive Guide To Precision And Versatility

- Laser Cut Wood Shapes Laser Cut Wood Shapes: Unleashing Creativity And Precision

- Laser Wood Cutouts Laser Wood Cutouts: A Comprehensive Guide To Crafting Precision And Intricacy

1. Hardwoods

- Oak: Durable, dense, and resistant to wear and tear. Produces intricate cuts with a smooth finish.

- Mahogany: Rich, reddish-brown color. Known for its durability and resistance to rot.

- Walnut: Deep, dark color with a fine grain. Offers high strength and dimensional stability.

- Birch Plywood: Made from thin layers of birch veneer. Strong, durable, and resistant to warping.

- Baltic Birch Plywood: Similar to birch plywood, but with a higher grade and more uniform grain.

- Marine Plywood: Water-resistant and highly durable. Suitable for outdoor applications exposed to moisture.

- Precision Cuts: Lasers provide precise and repeatable cuts, eliminating the need for manual labor.

- Intricate Designs: Lasers can cut intricate patterns and designs, which would be difficult or impossible to achieve with traditional methods.

- Mass Production: Laser cutting allows for mass production of identical parts with consistent quality.

- Reduced Waste: Laser cutting minimizes waste by cutting only the necessary material, reducing material costs.

- Cost: Laser cutting machines can be expensive to purchase and maintain.

- Smoke and Fumes: Laser cutting wood produces smoke and fumes, which require proper ventilation.

- Burn Marks: If the laser settings are not optimized, burn marks can appear on the cut edges.

- Charring: High-power lasers can char the wood, affecting the aesthetic appearance.

DOWNLOAD SVG FILES FOR LASER CUTTING

3. Plywood

Advantages of Laser Cutting Wood

Disadvantages of Laser Cutting Wood

Tips for Optimizing Laser Cutting Wood

1. Choose the Right Wood Type: Select wood based on the desired properties and application.

2. Prepare the Wood: Ensure the wood is clean, dry, and free from knots or blemishes.

3. Set the Laser Parameters: Adjust the laser power, speed, and focus to optimize the cut quality.

4. Use a Raster Pattern: For complex designs, use a raster pattern to prevent burn marks.

5. Ventilate the Area: Ensure proper ventilation to remove smoke and fumes.

6. Clean the Machine: Regularly clean the laser machine to maintain optimal performance.

Conclusion

Laser cutting wood offers numerous advantages for woodworking projects. By understanding the different types of wood and optimizing the laser parameters, you can achieve precise, intricate, and efficient cuts. Whether you’re a hobbyist or a professional, laser cutting wood can enhance your creativity and productivity.

FAQs

1. What is the best type of wood for laser cutting?

The best wood type depends on the desired properties and application. Oak, mahogany, and walnut are popular hardwoods, while pine, fir, and cedar are suitable softwoods.

2. How can I prevent burn marks when laser cutting wood?

Use a raster pattern, reduce the laser power, or increase the cutting speed.

3. How can I minimize smoke and fumes when laser cutting wood?

Ensure proper ventilation by using an exhaust system or working in an open area.

4. What are the safety precautions for laser cutting wood?

Wear appropriate safety gear, including eye protection, gloves, and a respirator. Keep the work area clean and clear.

5. Can I laser cut wood that has been stained or painted?

Yes, but it’s important to adjust the laser parameters accordingly to prevent damage to the finish.