Wooden Laser Cutting: A Comprehensive Guide

Introduction

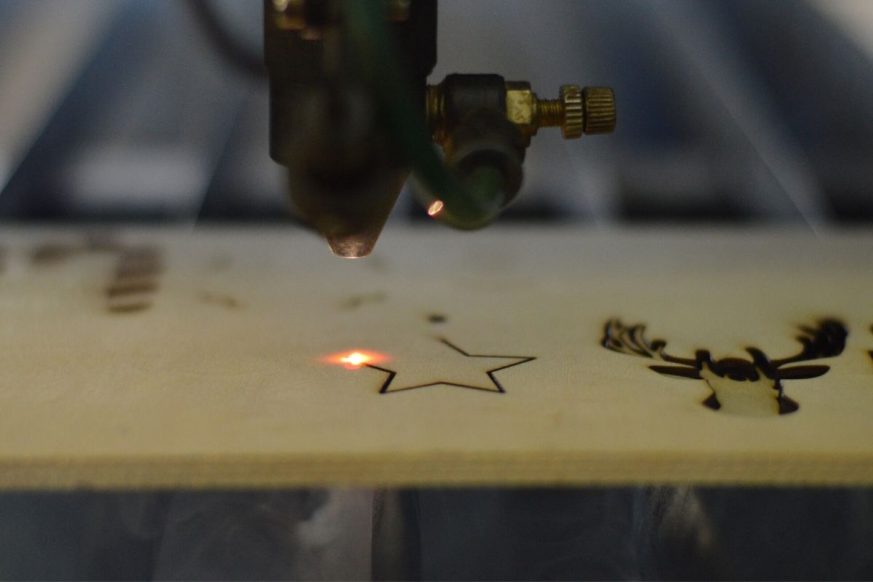

Wooden laser cutting is a cutting-edge technology that utilizes focused laser beams to precisely cut, engrave, and shape wood. This advanced process enables the creation of intricate designs, detailed engravings, and customized wood products with unmatched precision and efficiency.

Table of Content

Advantages of Wooden Laser Cutting

Speed and Efficiency: Laser cutting offers rapid processing speeds, significantly reducing production time compared to traditional cutting methods. This efficiency allows for increased productivity and cost savings.

Versatility: Laser cutters can handle a wide range of wood types and thicknesses, providing versatility for various applications. From delicate veneers to thick planks, laser cutting can accommodate diverse material requirements.

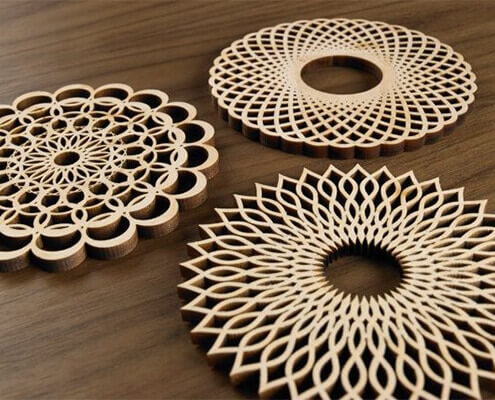

Intricate Designs: Laser cutting excels in creating complex designs that would be difficult or impossible to achieve manually. Intricate patterns, fine details, and intricate curves can be precisely cut with ease.

Engraving Capabilities: In addition to cutting, laser cutters can also engrave designs, text, and images onto wood surfaces. This engraving capability expands the creative possibilities and allows for personalized and decorative applications.

Types of Laser Cutters

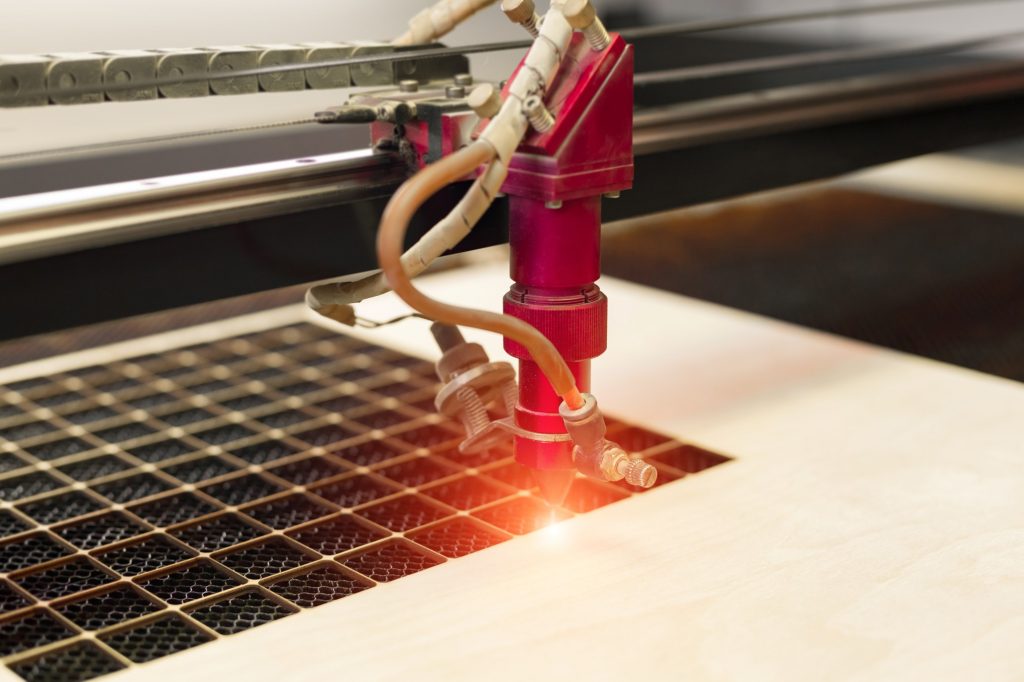

CO2 Laser Cutters: CO2 lasers are commonly used for wood cutting due to their high power and ability to achieve fine details. They are suitable for a wide range of wood materials and thicknesses.

DOWNLOAD SVG FILES FOR LASER CUTTING

Fiber Laser Cutters: Fiber lasers offer higher cutting speeds and are particularly effective for cutting thinner wood materials. They provide excellent beam quality and minimal heat-affected zones.

Applications of Wooden Laser Cutting

Signage and Display: Laser-cut wood can be used to create eye-catching signage, displays, and decorative elements for businesses and events.

Furniture and Home Decor: Laser cutting enables the production of intricate furniture pieces, decorative panels, and unique home accessories with precise details.

Wooden laser cutting is a cutting-edge technology that utilizes focused laser beams to precisely cut, engrave, and shape wood. This advanced process enables the creation of intricate designs, detailed engravings, and customized wood products with unmatched precision and efficiency.

- Laser Drawing On Wood Laser Drawing On Wood: A Comprehensive Guide To Pyrography And Laser Engraving

- Laser Cut Wood Signs Laser Cut Wood Signs: A Comprehensive Guide

- Laser Cut Wood Near Me Laser Cut Wood Near Me: A Comprehensive Guide To Finding Local Laser Cutting Services

- Laser Wood Products Laser Wood Products: A Comprehensive Guide To Innovation And Precision

- Laser Cut Wood Bookmarks Laser Cut Wood Bookmarks: A Creative And Personal Touch To Your Reading

Advantages of Wooden Laser Cutting

Precision and Accuracy: Laser cutting provides exceptional precision, delivering clean, sharp cuts with minimal distortion. This accuracy ensures consistent results and eliminates the need for extensive post-processing.

DOWNLOAD SVG FILES FOR LASER CUTTING

Speed and Efficiency: Laser cutting offers rapid processing speeds, significantly reducing production time compared to traditional cutting methods. This efficiency allows for increased productivity and cost savings.

Versatility: Laser cutters can handle a wide range of wood types and thicknesses, providing versatility for various applications. From delicate veneers to thick planks, laser cutting can accommodate diverse material requirements.

Intricate Designs: Laser cutting excels in creating complex designs that would be difficult or impossible to achieve manually. Intricate patterns, fine details, and intricate curves can be precisely cut with ease.

Toys and Games: Laser cutters can create custom toys, puzzles, and game components with intricate shapes and designs.

Packaging and Boxes: Laser cutting can be used to create custom packaging solutions, such as boxes, crates, and display cases, with precise dimensions and intricate patterns.

Considerations for Wooden Laser Cutting

Material Selection: The type of wood used will impact the cutting results. Softwoods like pine and cedar cut faster, while hardwoods like oak and mahogany require higher laser power and slower cutting speeds.

Laser Power: The laser power determines the thickness and speed at which wood can be cut. Higher laser power enables faster cutting and thicker material handling.

Cutting Speed: Cutting speed should be adjusted based on the material thickness and desired cut quality. Faster speeds may compromise precision, while slower speeds ensure cleaner cuts.

Focus: Proper focus of the laser beam is crucial for achieving optimal cutting results. Incorrect focus can lead to uneven cuts or incomplete penetration.

Safety Precautions

Laser Safety: Laser cutting requires proper safety measures, including wearing protective eyewear, ensuring adequate ventilation, and avoiding exposure to the laser beam.

Fire Hazard: Wood is a flammable material, so proper fire safety precautions should be taken during laser cutting. A fire extinguisher and smoke detector should be readily available.

Conclusion

Wooden laser cutting is a powerful technology that empowers makers, designers, and businesses to create unique and intricate wood products with unmatched precision, speed, and versatility. By understanding the advantages, applications, considerations, and safety precautions involved in wooden laser cutting, users can harness this technology to unlock a world of creative possibilities and drive innovation in various industries.

FAQs

Q: What is the best wood for laser cutting?

A: Softwoods like pine and cedar are easier to cut, while hardwoods like oak and mahogany require higher laser power.

Q: How thick of wood can a laser cutter cut?

A: The thickness of wood that can be cut depends on the laser power and type. Typically, CO2 lasers can cut up to 1/2 inch, while fiber lasers can cut thinner materials more efficiently.

Q: Can laser cutters engrave wood?

A: Yes, laser cutters can engrave designs, text, and images onto wood surfaces.

Q: Are laser cutters safe?

A: Laser cutting requires proper safety precautions, including wearing protective eyewear, ensuring adequate ventilation, and avoiding exposure to the laser beam.