Laser Cut Wooden Blanks: A Comprehensive Guide

H1: Introduction

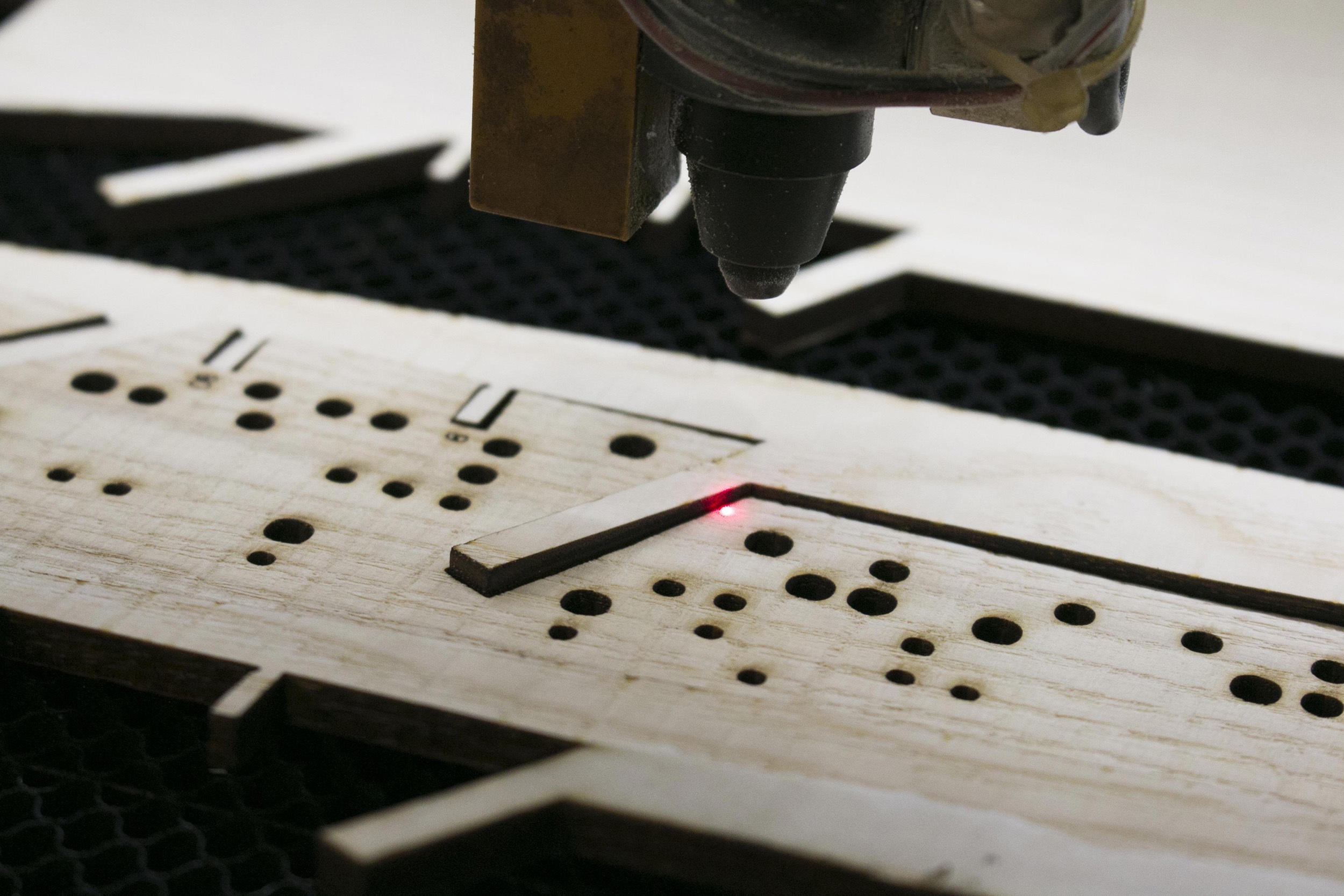

Laser cut wooden blanks are versatile materials used in a wide range of crafting and DIY projects. They are precisely cut from high-quality wood using laser technology, offering intricate designs and smooth finishes. This article explores the advantages, applications, and best practices for working with laser cut wooden blanks.

Table of Content

- 1 Laser Cut Wooden Blanks: A Comprehensive Guide

- 1.1 H1: Introduction

- 1.2 H2: Advantages of Laser Cut Wooden Blanks

- 1.3 H3: Applications of Laser Cut Wooden Blanks

- 1.4 H2: Advantages of Laser Cut Wooden Blanks

- 1.5 H2: Best Practices for Working with Laser Cut Wooden Blanks

- 1.6 H2: Finishing Techniques for Laser Cut Wooden Blanks

- 1.7 H3: Conclusions

- 1.8 FAQs

H2: Advantages of Laser Cut Wooden Blanks

DOWNLOAD SVG FILES FOR LASER CUTTING

H3: Applications of Laser Cut Wooden Blanks

- Home Décor: Create decorative wall art, coasters, picture frames, and other home accessories.

- Toys: Make custom toys, puzzles, and educational games for children.

- Wood Laser Printing H1: Wood Laser Printing: A Comprehensive Guide To Engraving And Etching On Wood

- Laser Wood Engraver And Cutter Laser Wood Engraver And Cutter: A Comprehensive Guide

- Laser Wood Cut Out Laser Wood Cut Out: A Comprehensive Guide To Precision Cutting And Artistic Expression

- Custom Cut Wood Shapes Custom Cut Wood Shapes: Elevate Your Projects With Precision And Creativity

- Laser Wood Carving Near Me Laser Wood Carving Near Me: An In-Depth Guide

- Precision Cutting: Laser cutting ensures precise and accurate cuts, eliminating the need for manual labor and reducing waste.

- Intricate Designs: Lasers can create complex and detailed designs that would be difficult or impossible to achieve with traditional cutting methods.

- Smooth Finishes: Laser cutting leaves a smooth and polished finish, minimizing the need for additional sanding or finishing.

- Jewelry: Design unique pendants, earrings, and bracelets.

- Craft Supplies: Use laser cut wooden blanks as embellishments for scrapbooks, greeting cards, and other crafts.

- Industrial Applications: Laser cut wooden blanks can be used in manufacturing, packaging, and other industrial settings.

- Choose High-Quality Wood: Select wood species that are suitable for your project and have a smooth, even grain.

- Use Proper Safety Equipment: Wear eye protection, gloves, and a dust mask when operating a laser cutter.

- Optimize Laser Settings: Adjust the laser power, speed, and focus to achieve the desired cut quality and depth.

- Secure the Blank: Ensure that the laser cut wooden blank is securely fastened to the cutting surface to prevent movement during the cutting process.

- Ventilate the Area: Laser cutting generates fumes, so it is important to work in a well-ventilated area.

- Sanding: Lightly sand the surface of the wooden blank to remove any rough edges or burrs.

- Staining or Painting: Apply stain or paint to enhance the appearance of the wooden blank and protect it from moisture.

- Finishing with a Clear Coat: Seal the wooden blank with a clear coat, such as polyurethane or lacquer, to protect it from damage and enhance its durability.

- What types of wood can be laser cut?

- A wide range of wood species can be laser cut, including hardwoods like oak, maple, and walnut, and softwoods like pine and cedar.

- What is the maximum thickness of wood that can be laser cut?

- The maximum thickness of wood that can be laser cut depends on the laser cutter’s power and capabilities. Most laser cutters can handle wood up to 1/4 inch thick.

- Can laser cut wooden blanks be used outdoors?

- Yes, but it is important to apply a protective finish to the wooden blank to protect it from moisture and UV rays.

- How do I clean laser cut wooden blanks?

- Use a soft cloth or brush to remove dust and debris. For deeper cleaning, use a mild soap solution and dry thoroughly.

Laser cut wooden blanks are versatile materials used in a wide range of crafting and DIY projects. They are precisely cut from high-quality wood using laser technology, offering intricate designs and smooth finishes. This article explores the advantages, applications, and best practices for working with laser cut wooden blanks.

H2: Advantages of Laser Cut Wooden Blanks

DOWNLOAD SVG FILES FOR LASER CUTTING

H2: Best Practices for Working with Laser Cut Wooden Blanks

H2: Finishing Techniques for Laser Cut Wooden Blanks

H3: Conclusions

Laser cut wooden blanks offer numerous advantages and applications for crafters and DIY enthusiasts. By choosing high-quality wood, using proper safety equipment, and optimizing laser settings, you can create precise, intricate, and durable wooden projects. With a variety of finishing techniques available, you can customize laser cut wooden blanks to suit your specific needs and preferences.

FAQs